DMG MORI Open House Pfronten 2020

“We’re still going full speed ahead!” And DMG MORI keeps its word! The world market leader will be presenting the first full speed results of the new year at the Open House in Pfronten. In focus: integrated digitalization concepts, pioneering shop floor technologies and intelligent automation solutions.

Stable and innovative in challenging times

- Integrated digitization: from DMG MORI Connectivity and CELOS update to end-to-end service optimization

- my DMG MORI: unique customer portal for automated service and spare parts management – with WERKBLiQ upgrade also for third-party products

- TULIP – the easy entry to digitalization

- 15 integrated automation solutions – directly ex works, everything from a single source

- World premieres: DMC 65 H monoBLOCK – the revolution in universal horizontal machining

- World premieres: PH CELL – modular automation for up to 40 pallets

- World premieres: LASERTEC 400 Shape – laser structuring of XXL molds

- ADDITIVE MANUFACTURING: End-to-end expertise – from drawing to finished part

- DMG MORI Economic Stimulus Program: strong partner for every economic situation with attractive financing concepts

“We’re still going full speed ahead!” Christian Thönes, Chairman of the Executive Board of DMG MORI AKTIENGESELLSCHAFT, gave an impressive signal during EMO 2019 in September with this promise. And DMG MORI keeps its word! At the traditional Open House from February 11th to 15th, 2020, DMG MORI will present itself as a driver of innovation in the areas of digitalization and automation. The focus will be on end-to-end connectivity as the standard for all machines, the CELOS update of all existing versions, the new customer portal my DMG MORI and TULIP as an ideal entry into digitalization. The majority of the exhibits demonstrate the automation expertise that the machine tool manufacturer offers with integral solutions from a single source. DMG MORI will show pioneering manufacturing concepts in machining and ADDITIVE MANUFACTURING on a space of more than 7,500 m². Three world premieres will round off the exhibition portfolio: the DMC 65 H monoBLOCK, a revolutionary universal horizontal machining center, the modular PH CELL pallet system and the LASERTEC 400 Shape for laser texturing.

Integrated digitization: from DMG MORI Connectivity and CELOS update to end-to-end service optimization

Few companies have been as successful as DMG MORI in digitally enhancing and expanding its traditional business with machine tools and services for many years. In this context, the APP-based operating and control system CELOS, which was first presented to the worldwide trade public at EMO in 2013, is regarded as groundbreaking for the branch. Since then, many pioneering innovations have been launched into the future. Today, CELOS alone is used in the control systems of more than 20,000 DMG MORI machines worldwide. DMG MORI PLANNING & CONTROL and the manufacturer-independent maintenance and repair platform WERKBLiQ are also are also shining success stories. As a founding member of ADAMOS GmbH, DMG MORI set the course early on for networked value creation in times of platform economy. On top of this come the latest EMO highlights:

- DMG MORI Connectivity is ensuring the secure networking of DMG MORI machines and selected third-party products.

- Moreover, CELOS customers can now perform a PLC-independent CELOS update to their current version. This applies to all existing CELOS versions over the past six years.

- The new DMG MORI MESSENGER uses configurable dashboards to display the current status of the machines at a glance and can now also be used for all machines and devices networked with DMG MORI Connectivity in production.

my DMG MORI: Unique customer portal for automated service and spare parts management – with WERKBLiQ upgrade also for third-party products

Since its world premiere at the EMO, the new customer portal my DMG MORI has been offering unique efficiency, with visible success. 4,000 customers had already registered their machinery free of charge after just a few weeks. The target is 20,000 users by the end of 2020. The reason for the lightning-fast start: my DMG MORI offers the shop floor a seamless range of innovative functions for integrated control, monitoring and documentation of all machine-oriented service processes.

Service requests are thus able to be started and sent virtually at the press of a button via my DMG MORI. Whereby the interactive request form prevents any misunderstandings. Specific service requests and optionally attached photos or videos directly reach the right DMG MORI service expert. Moreover, the “Tracking & Tracing” function ensures transparency for all service processes and procedures. Even orders for spare parts can be tracked down to the exact minute. Moreover, the unique functionality of my DMG MORI doesn’t need to be limited to DMG MORI. With a barrier-free upgrade to the maintenance and servicing platform WERKBLiQ, customers can access the full range of my DMG MORI services for their entire fleet of machines – including the optimization of all maintenance processes.

TULIP – the easy entry to digitalization

The cooperation between DMG MORI and the US software provider TULIP is also celebrating its Pfronten premiere. Several hundred networked TULIP workstations will be in use by then and ready to be presented at the Open House. Above all, this applies to live insights into TULIP use case examples in spindle manufacturing at the production site in Pfronten.

The core idea behind the TULIP solutions is simplicity itself: Manual workflows when operating the machinery or assembly processes are visualized step by step via TULIP apps and augmented with the relevant data. The system guides the operator through every individual process step and records all relevant (digital) data on the status “along the way”. A large number of representative use cases are available to the customer in an app library as adaptable “samples” to “record” the process. Users can also make use of the no-code platform of TULIP to independently create manufacturing apps without any IT know-how or special programming skills. DMG MORI thus places people right at the center of digitalization and leaves full personal responsibility on the shop floor. This is another reason why DMG MORI is convinced that TULIP solutions will make it significantly easier for small- and medium-sized customers in particular to gain entry to digital manufacturing.

15 integral automation solutions – directly ex works, everything from a single source

In the future DMG MORI will offer all machine tools in its portfolio with automation solutions in order to meet the hugely increasing demand. Rapid growth in the three-digit range is expected. DMG MORI will be demonstrating 15 automation solutions at their Open House, including the new PH CELL on a DMU 65 monoBLOCK, a DMC 90U duoBLOCK with PH-AGV 50 and a CTX beta 1250 TC with Robo2Go Vision.

The PH-AGV 50 (automated guided vehicle) is an autonomous system for pallet automation. This innovative solution offers a flexible automation layout with free access to the machine and an intelligent safety concept for human-machine collaboration. The Robo2Go Vision is a further development of flexible robot automation and enables direct loading of Euro pallets and, thanks to the new 3D-camera, achieves robust recognition without the need of any specific workpiece racks – there is therefore no need to restack the workpieces.

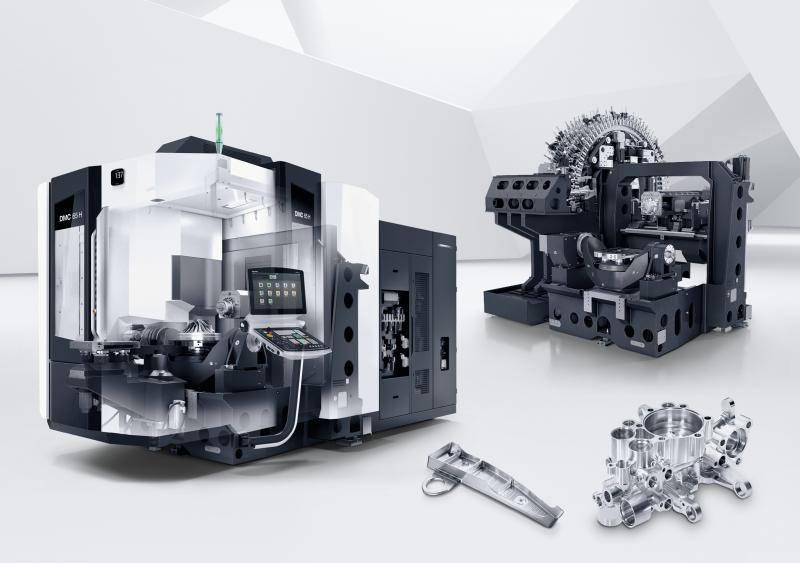

World premieres: DMC 65 H monoBLOCK – the revolution in universal horizontal machining

With the DMC 65 H monoBLOCK, DMG MORI presents a new highlight in horizontal machining. The unique machine concept unites the flexibility and ergonomics of a 5-axis vertical machine with the productivity and process reliability of a horizontal machining center. The optimal chip fall makes the world-premiere machine particularly suitable for process-reliable machining of aerospace structural components. People working in the area of dies and molds benefit from the possibility of machining components directly with deep hole bores of up to 550 mm on one machine. Contract manufacturers in particular value the flexibility provided by the swivel rotary table mounted on both sides and the ingenious workspace. This makes it possible to machine both high clamping towers and 5-axis components weighing up to 600 kg. The thermo-symmetric construction of the inherently rigid machine bed, including 3-point support, ensures maximum long-term accuracy.

World premieres: PH CELL – modular automation for up to 40 pallets

A new PH CELL pallet system with a footprint of 10.7 m² will be presented by DMG MORI on a DMU 65 monoBLOCK. The side loading into the machine tool guarantees optimal ergonomics and accessibility to the workspace. The pallet system has a modular design and offers the highest flexibility. The basic version with one shelf module can accommodate up to 12 500 x 500 mm pallets, 16 400 x 400 mm pallets or up to 20 320 x 320 mm pallets distributed over three or four shelves. The system can also be expanded by a second shelf module, making up to 40 pallet storage spaces available. The second shelf module can be retrofitted without the need for any additional space. A separate and optionally rotatable setup station allows ergonomic setup while machining. The PH Cell is an attractively priced automation unit in the DMG MORI VERTICO design and, with a defined interface and a modular principle, is able to be put into operation very quickly.

World premieres: LASERTEC 400 Shape – laser structuring of XXL molds

The new LASERTEC 400 Shape expands the DMG MORI portfolio in 5-axis laser structuring into the range of large molds up to

3,350 x 1,350 x 1,000 mm with a workpiece weight of up to 20,000 kg. The newly developed laser head swivels from -100° to +135° and has a rotation range of +/-200°, which makes it possible to produce undercuts. The ergonomic and thermo-symmetric gantry design of the LASERTEC 400 Shape ensures maximum precision and outstanding texturing quality. The new top model works up to three times faster at this level of quality, thanks to high-performance texturing. The LASERTEC 400 Shape thus opens up the possibility of an infinite number of textures in reproducible quality and with functional features such as scratch resistance, water-repellent properties or gloss.

ADDITIVE MANUFACTURING: end-to-end expertise – from drawing to finished part

As a global partner in the additive manufacturing of metal components, DMG MORI provides the rapidly expanding technology field with innovative developments and a holistic advisory service. Additive manufacturing is becoming increasingly established as a pioneering procedure for industrial use. The demands placed on the technology are therefore also changing. DMG MORI consistently takes this into consideration in the further development of its LASERTEC 3D hybrid, LASERTEC 3D and LASERTEC SLM model series. The main topics are the technical availability of the machines, their productivity, the component quality and occupational safety. As a highlight in Pfronten, the innovator is presenting the new LASERTEC 125 3D hybrid – introduced for the first time at the formnext 2019 in Frankfurt am Main. With this latest model, users can now also clamp large parts and molds. Based on the sturdy monoBLOCK series, it is designed for parts measuring up to ø 1,250 x 745 mm and a workpiece weight of up to 2,000 kg. The rigid machine construction and high dynamics of the LASERTEC 125 3D hybrid enable accurate, reliable and, at the same time, cost-effective complete machining of complex 3D parts. A key unique selling point of laser deposition welding is the possibility it offers of changing between two materials quickly and CNC-controlled. Hard welding to reduce wear can be specifically carried out in one area while at the same time corrosion-resistant welding for the prevention of environmental impacts is carried out in another area.

DMG MORI Economic Stimulus Program: strong partner for every economic situation with attractive financing concepts

After years of growth, many DMG MORI customers now face uncertain economic times. The machine tool manufacturer is taking advantage of its global presence and unique and wide range of services and products to position itself as a reliable partner especially in this situation. Based on a

comprehensive five-point Economic Stimulus Program, DMG MORI is able to provide its customers on the economic level with long-term support in the area of further training as well as service and machine technology. All measures perfectly complement one another and are all from a single source. The DMG MORI Economic Stimulus Program includes buy back, i.e. a machine buy back for more liquidity, attractive financing concepts without risk such as renting, buying or leasing by DMG MORI Finance as well as training courses at the DMG MORI Academy to increase manufacturing expertise. Moreover, DMG MORI Full Service enables carefree production, while DMG MORI Used Machines offers machine overhaul as an interesting alternative to new purchases.

Germany

Germany