GRINDTEC 2018

With ULTRASONIC-technology and a diverse laser machining portfolio DMG MORI will be presenting its entire range for grinding applications at the GRINDTEC 2018.

Holistic production of precision tools

- Laser machining in PKD, CVD-D and CBN

- ULTRASONIC machining of carbide tool bodies

- Highly stable vertical multi-process grinding

- Complex 3D components using selective laser melting

- Holistic and integral software solutions

DMG MORI will be demonstrating its expertise and innovative manufacturing solutions for applications in grinding technology at the GRINDTEC from 14. to 17. March 2018. The 5-axis manufacturing solutions from the machine tool manufacturer include ultrasonic machining on the ULTRASONIC 20 linear and the laser machining of precision tools on the LASERTEC 20 PrecisionTool. In addition DMG MORI will be showcasing its VERTICAL MATE series for vertical multi-process grinding and in the field of additive manufacturing the LASERTEC 30 SLM, a system that produces complex 3D components using selective laser melting in a powder bed. Integral software solutions round off the exhibition programme in Hall 5 (booth 5069).

ULTRASONIC 20 linear:

Complete machining of carbide tool bodies using ULTRASONIC technology

For many years now DMG MORI has been offering high-performance machine tools with ULTRASONIC technology for the high-precision 5-axis machining of complex workpieces made of advanced materials. With the new ULTRASONIC 20 linear this series now captures an entirely new class. Spindle speeds of optionally up to 60,000 rpm, more powerful drive motors, an even smaller footprint plus CELOS with apps developed specifically for ULTRASONIC are among the innovations that users from the precision tool, optical, clock and watch, medical and high-precision mould construction sectors will benefit in future.

LASERTEC 30 SLM:

Complete solution for ADDITIVE MANUFACTURING in a powder bed

On the market for additive systems for selective laser melting the LASERTEC 30 SLM impresses with its flexibility, efficiency and process reliability. Its flexible powder module, for example, enables a powder change in under two hours. With its CELOS SLM DMG MORI also offers an integral software solution for CAM programming and machine control from a single source and with a uniform user interface. Thanks to the coordinated and uniform user interface components can be programmed and the data immediately transferred to the machine in the shortest possible of times – regardless of the complexity of the parts.

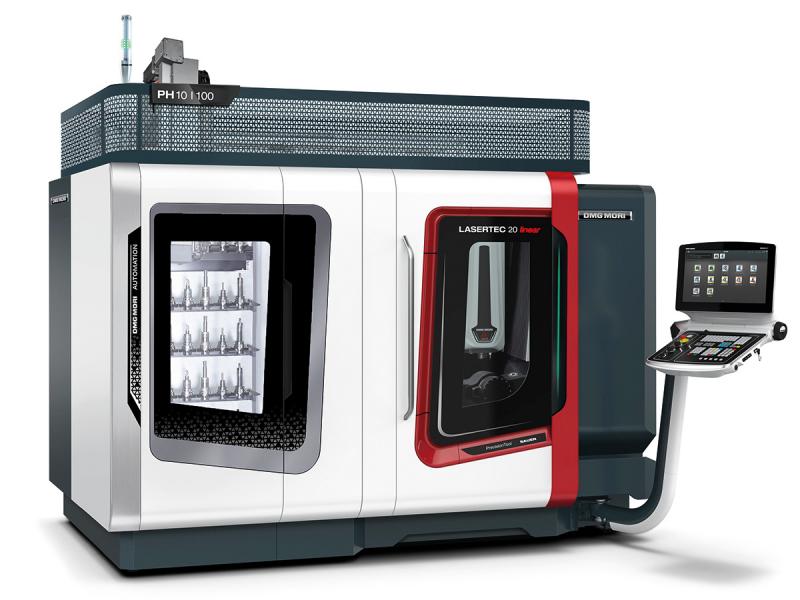

LASERTEC 20 PrecisionTool:

Perfect tools thanks to laser machining

The continuously rising demand for ultra-hard precision tools means that all tool producers are confronted with the challenge of ensuring the continuous, sustainable and cost-effective optimisation of their production processes. What is more, conventional, mechanical machining processes such as grinding and EDM can have a negative impact on the quality of the cutting edges. Innovative laser technology has proved to be the most efficient and most reliable solution in both cases. As a pioneer and market leader in the machining of ultra-hard materials DMG MORI has many years of experience in the laser machining of PKD, CVD-D and CBN as well as carbide. Its LASERTEC 20 PrecisionTool, for example, creates perfect cutting edges, whereby the tools produced in this way have a service life that is up to two and a half times that of conventionally produced tools.

VERTICAL MATE:

Highly stable vertical multi-process grinding

With the biggest share of the market in Japan, the VERTICAL MATE series from DMG MORI ranks as the most popular manufacturing solution there in the field of vertical multi-process grinding. Vertical clamping ensures high concentricity, shape and position tolerance as well as cylindrical dimensional accuracy. Maximum 1 µm concentricity. Grinding of inner and outer diameters and face grinding are also possible in a single setup. Depending on size the successful models have a swing diameter of ø 350 mm up to ø 1,250 mm and are designed for workpieces weighing from 200 kg to 2,500 kg. The highly stable grinding spindle is equipped with a 6x grinding disc changer, while in-process data enable automatic correction and the GriPS II dialogue programming software facilitates simple shopfloor programming.

Germany

Germany