Innovation: Robo2Go 3. Generation: Greater autonomy through increased capacity

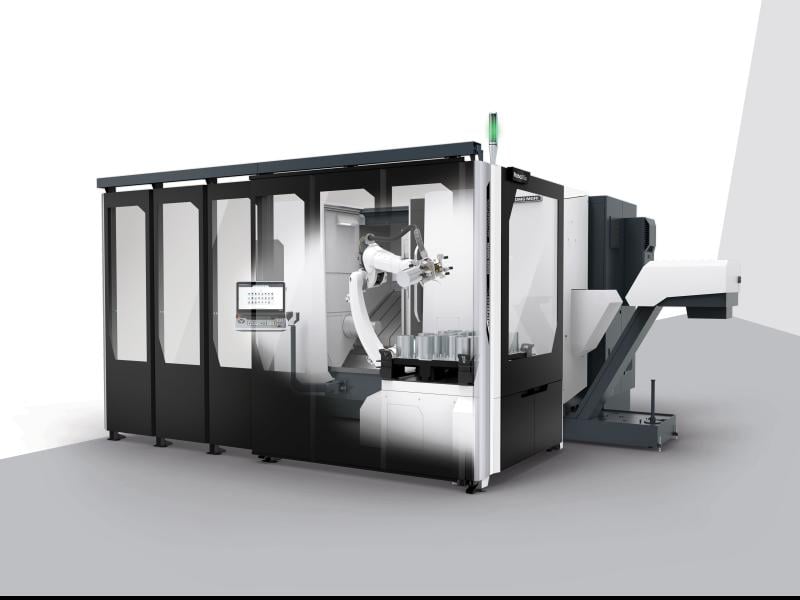

Munich. The automation of machining centers and lathes is a quick way to optimize production capacity utilization—especially with the help of workpiece handling systems that are easy to install and intuitive to operate. DMG MORI's Robo2Go Milling and Robo2Go Turning have proven themselves in this category for many years. At its in-house exhibition in Pfronten, the machine tool manufacturer is presenting the third generation of its flexible robot solution for small to medium batch sizes. The expansion of the workpiece storage capacity by up to 50 percent, well-thought-out installation layouts, and easy handling make this innovation a valuable upgrade for any production facility.

Redesigned storage solutions and optimal accessibility

DMG MORI has redesigned its storage solutions in particular to enable the Robo2Go 3. Generation to work even more autonomously. A standard Euro pallet increases capacity by twelve percent, while drawer storage has been expanded by 32 percent. In addition, a pallet station with three Euro pallets is available, which expands storage capacity by 50 percent. The increased capacity allows employees to significantly increase automated operation periods, giving them more time for demanding tasks in work preparation. With the new 70 kg module, larger and heavier workpieces weighing up to 40 kg can also be handled safely in a single grip. The Robo2Go 3. Generation thus closes the gap between the 35 kg module of the Robo2Go Turning and the 210 kg handling capacity of the Robo2Go Max, significantly expanding the range of applications.

To maintain accessibility to the machining centers and turn-mill machines, DMG MORI can position the Robo2Go 3. Generation on the right. This ensures that the working area, control panel, and tool magazine remain easily accessible. The left-hand installation option remains ideal for turret lathes in the CTX and NLX series when using the Robo2Go Turning.

Intuitive operation via machine control

The Robo2Go 3. Generation is intuitively operated via the Robo2Go app. No programming knowledge is required to create the process, as predefined program modules are used via drag & drop. The app is integrated into the machine control system, so NC programs do not need to be adapted separately. The Robo2Go Jobs app also allows you to manage your orders clearly. In combination with the drawer storage, the Robo2Go 3. Generation features the new Automation Control Station. The 19'' touchscreen in a robust aluminum housing offers maximum user-friendliness directly at the drawer storage.

Munich. The automation of machining centers and lathes is a quick way to optimize production capacity utilization—especially with the help of workpiece handling systems that are easy to install and intuitive to operate. DMG MORI's Robo2Go Milling and Robo2Go Turning have proven themselves in this category for many years. At its in-house exhibition in Pfronten, the machine tool manufacturer is presenting the third generation of its flexible robot solution for small to medium batch sizes. The expansion of the workpiece storage capacity by up to 50 percent, well-thought-out installation layouts, and easy handling make this innovation a valuable upgrade for any production facility.

Redesigned storage solutions and optimal accessibility

DMG MORI has redesigned its storage solutions in particular to enable the Robo2Go 3. Generation to work even more autonomously. A standard Euro pallet increases capacity by twelve percent, while drawer storage has been expanded by 32 percent. In addition, a pallet station with three Euro pallets is available, which expands storage capacity by 50 percent. The increased capacity allows employees to significantly increase automated operation periods, giving them more time for demanding tasks in work preparation. With the new 70 kg module, larger and heavier workpieces weighing up to 40 kg can also be handled safely in a single grip. The Robo2Go 3. Generation thus closes the gap between the 35 kg module of the Robo2Go Turning and the 210 kg handling capacity of the Robo2Go Max, significantly expanding the range of applications.

To maintain accessibility to the machining centers and turn-mill machines, DMG MORI can position the Robo2Go 3. Generation on the right. This ensures that the working area, control panel, and tool magazine remain easily accessible. The left-hand installation option remains ideal for turret lathes in the CTX and NLX series when using the Robo2Go Turning.

Intuitive operation via machine control

The Robo2Go 3. Generation is intuitively operated via the Robo2Go app. No programming knowledge is required to create the process, as predefined program modules are used via drag & drop. The app is integrated into the machine control system, so NC programs do not need to be adapted separately. The Robo2Go Jobs app also allows you to manage your orders clearly. In combination with the drawer storage, the Robo2Go 3. Generation features the new Automation Control Station. The 19'' touchscreen in a robust aluminum housing offers maximum user-friendliness directly at the drawer storage.