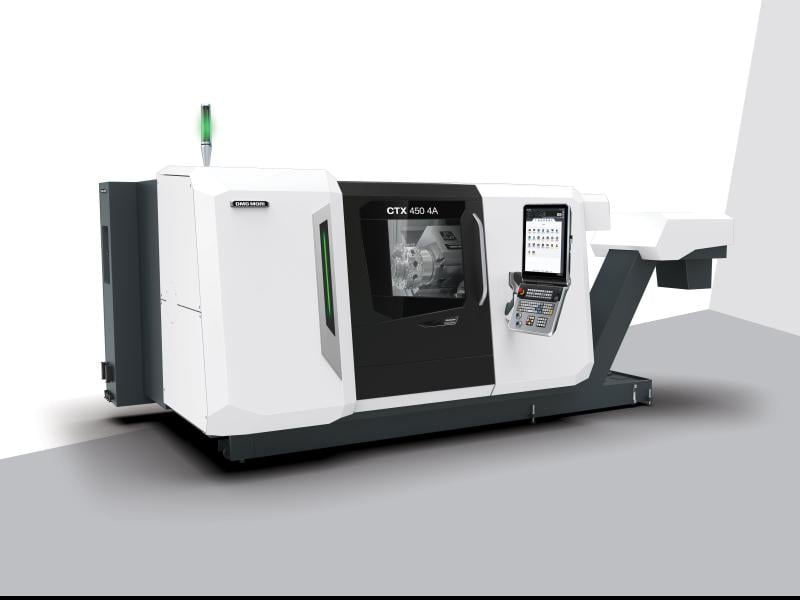

World premiere: CTX 450 4A: Universal turning center for complete 6-sided machining

Munich. DMG MORI is expanding its latest generation of universal turning centers with the new CTX 450 4A. A total of up to 36 tool positions on two tool carriers, which can work individually or together on the two spindles, give it maximum flexibility. The highly rigid machine design, the integrated cooling concept, Magnescale position measuring systems in both X-axes, the Y-axis and optionally also in the Z-axis ensure precise machining. The positioning accuracy is 6 µm or 12", enabling even small and medium-sized companies to meet the requirements of demanding industries.

Large working space, versatile spindle range, and powerful turrets

Measuring just 10.8 m², the CTX 450 4A is a versatile turning center that paves the way for the future of manufacturing. The two spindles and multiple turrets enable efficient 6-sided complete machining of workpieces up to ø 430 x 700 mm. The Y-axis travels +/- 65 mm. Even in the standard configuration, the spindles guarantee powerful and efficient turning. On the left, an ISM 80 with 4,500 rpm and 280 Nm is at work, and on the right, an ISM 65 with 5,500 rpm and 171 Nm. An ISM 102 with 3,500 rpm and 620 Nm and an ISM 80 with 4,500 rpm and 280 Nm are available as options, supporting heavy-duty machining applications. The bar passage of up to ø 102 mm is the best in its class. Performance and flexibility continue with the turrets. The upper turret offers space for either 12 or 16 VDI 40 tools, while the lower turret accommodates 12 stations. Both mill or drill at 12,000 rpm and 38 Nm. DMG MORI can optionally equip the CTX 450 4A with VDI-30 turrets—the upper one with up to 20 tool stations and the lower one with 16 tools.

More productive manufacturing through automation and digitization

DMG MORI combines efficient complete machining on the CTX 450 4A with customized automation solutions. An unloading device is integrated ex works, which removes workpieces up to ø 100 x 350 mm and 4 kg. In addition, workpiece handling can be further expanded with the help of Robo2Go Turning. Automated production plays a key role in optimizing machine utilization and increasing overall production productivity. At the same time, the machine's perfect connectivity and the app-based CELOS X control platform—both on a Siemens SINUMERIK ONE or MAPPS with —ensure a quick start to the digitization of entire manufacturing processes. DMG MORI technology cycles such as the tool balancing assistant and Multi-Threading Pro reduce the effort required for programming, for example.

Sustainability as a competitive advantage

Sustainable manufacturing offers enormous competitive advantages for both ecological and economic reasons. With various measures—summarized under GREENMODE—DMG MORI is specifically increasing the resource efficiency and productivity of its machines. Thanks to innovative hardware components and software, energy consumption can be reduced by more than 30% depending on the machine, for example with low-friction linear guides, highly efficient coolers, the demand-based supply of cooling lubricants with "Adaptive Coolant Flow" or automatic air leakage monitoring with "Air Leakage Monitoring."

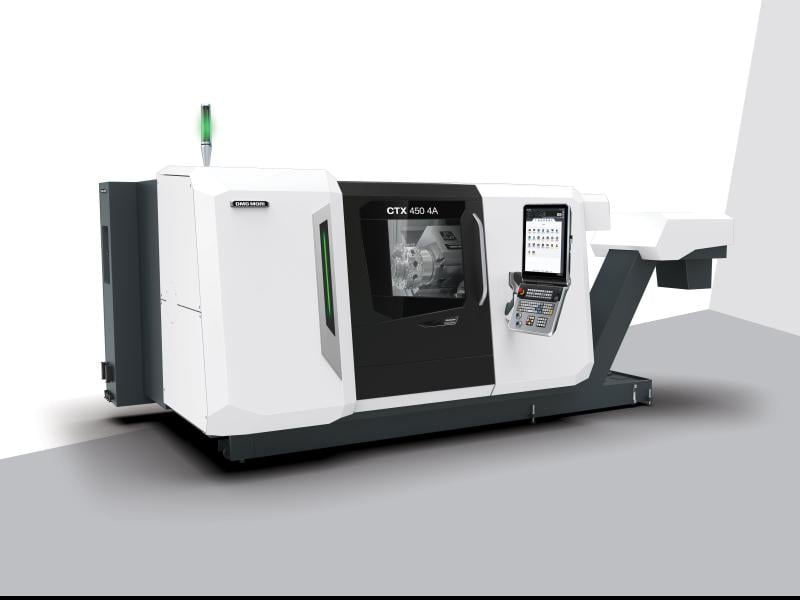

Munich. DMG MORI is expanding its latest generation of universal turning centers with the new CTX 450 4A. A total of up to 36 tool positions on two tool carriers, which can work individually or together on the two spindles, give it maximum flexibility. The highly rigid machine design, the integrated cooling concept, Magnescale position measuring systems in both X-axes, the Y-axis and optionally also in the Z-axis ensure precise machining. The positioning accuracy is 6 µm or 12", enabling even small and medium-sized companies to meet the requirements of demanding industries.

Large working space, versatile spindle range, and powerful turrets

Measuring just 10.8 m², the CTX 450 4A is a versatile turning center that paves the way for the future of manufacturing. The two spindles and multiple turrets enable efficient 6-sided complete machining of workpieces up to ø 430 x 700 mm. The Y-axis travels +/- 65 mm. Even in the standard configuration, the spindles guarantee powerful and efficient turning. On the left, an ISM 80 with 4,500 rpm and 280 Nm is at work, and on the right, an ISM 65 with 5,500 rpm and 171 Nm. An ISM 102 with 3,500 rpm and 620 Nm and an ISM 80 with 4,500 rpm and 280 Nm are available as options, supporting heavy-duty machining applications. The bar passage of up to ø 102 mm is the best in its class. Performance and flexibility continue with the turrets. The upper turret offers space for either 12 or 16 VDI 40 tools, while the lower turret accommodates 12 stations. Both mill or drill at 12,000 rpm and 38 Nm. DMG MORI can optionally equip the CTX 450 4A with VDI-30 turrets—the upper one with up to 20 tool stations and the lower one with 16 tools.

More productive manufacturing through automation and digitization

DMG MORI combines efficient complete machining on the CTX 450 4A with customized automation solutions. An unloading device is integrated ex works, which removes workpieces up to ø 100 x 350 mm and 4 kg. In addition, workpiece handling can be further expanded with the help of Robo2Go Turning. Automated production plays a key role in optimizing machine utilization and increasing overall production productivity. At the same time, the machine's perfect connectivity and the app-based CELOS X control platform—both on a Siemens SINUMERIK ONE or MAPPS with —ensure a quick start to the digitization of entire manufacturing processes. DMG MORI technology cycles such as the tool balancing assistant and Multi-Threading Pro reduce the effort required for programming, for example.

Sustainability as a competitive advantage

Sustainable manufacturing offers enormous competitive advantages for both ecological and economic reasons. With various measures—summarized under GREENMODE—DMG MORI is specifically increasing the resource efficiency and productivity of its machines. Thanks to innovative hardware components and software, energy consumption can be reduced by more than 30% depending on the machine, for example with low-friction linear guides, highly efficient coolers, the demand-based supply of cooling lubricants with "Adaptive Coolant Flow" or automatic air leakage monitoring with "Air Leakage Monitoring."