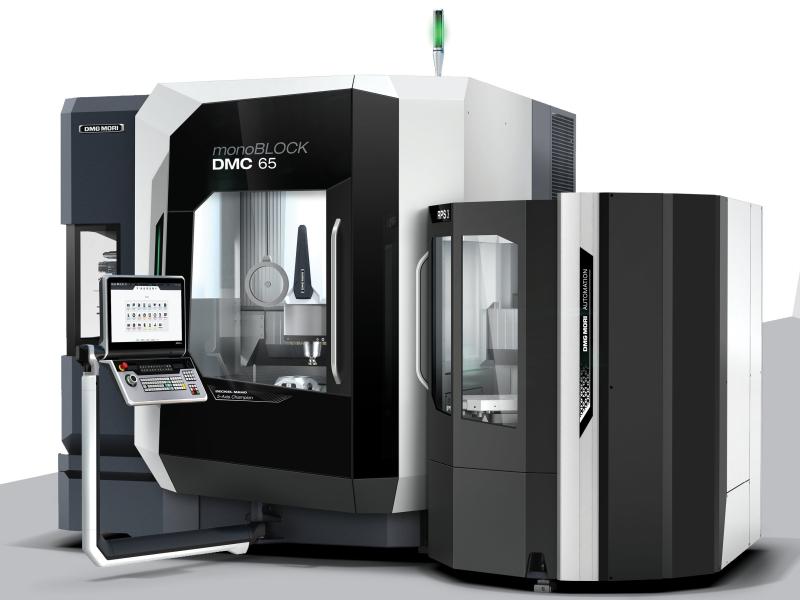

World Premiere: DMC 65/75 monoBLOCK 2. Generation: Precision and process integration in the smallest

Munich. Aviation & Space, Die & Mold or Mobility - the versatility of the DMC monoBLOCK series from DMG MORI has always proven itself in numerous industries. The DMC 65 monoBLOCK 2. Generation and DMC 75 monoBLOCK 2. Generation will continue this success story. The two 5-axis simultaneous machining centers produce complex workpieces up to ø 630 x 500 mm and 600 kg on a footprint of just 8 m². The key to even more efficient machining is the integration of several processes in one clamping. The DMC 65 monoBLOCK 2. Generation combines six technologies on request: Milling, turning at up to 1,200 min-1, grinding, gear cutting, in-process measuring and Ultrasonic.

„Ready for Automation“

DMG MORI has taken the challenges of modern production into account and developed successors that work even more precisely, flexibly and economically and can be used both as a standalone variant and automated at the same time. In keeping with the motto "Ready for Automation", the work area door opens to the left, enabling perfect automation integration. The DMC series consistently implements unrestricted access to the work area, tool magazine and set-up station from the front - the only machine concept of its kind.

Depending on the application, customers can choose from a wide range of automation solutions. In addition to the RPS 3 rotary storage system or the PH Cell pallet handling system, the Robo2Go Milling workpiece handling system or the MATRIS WPH combined workpiece and pallet handling system can also be connected, depending on the application. Driverless transport systems from the AMR series are also ideal for automation.

4 µm positioning accuracy

The DMC 65/75 monoBLOCK 2. Generation is characterized by its outstanding accuracy and reliability. The 3-point support ensures optimum stability and maximum machining performance. Thanks to the stable design with a large-volume slide and 45 mm wide roller guides in all axes, excellent long-term accuracy is guaranteed.

Large ball screws with a diameter of up to 50 mm also contribute to the high precision of the machine. Extensive cooling measures in the basic machine, multi-sensor compensation, and thermosymmetrical ram cooling result in higher accuracy and better surface quality. Overall, a positioning accuracy of 4 µm is achieved, making the DMC 65/75 monoBLOCK 2. Generation an ideal choice for demanding machining tasks.

Wide range of MASTER spindles and up to 240 tools integrated into the machine

The wide range of spindles allows the DMC 65 monoBLOCK 2. Generation to be equipped for specific applications. The range extends from speeds of up to 30,000 rpm to torques of up to 200 Nm. All MASTER spindles come with a 36-month warranty with no limit on operational hours and technical availability of over 96 percent. A machine-integrated tool magazine with up to 240 pockets ensures minimal non-productive times on the

DMC 65/75 monoBLOCK 2. Generation, even in high-mix single-part and small-batch production.The DMC 75 monoBLOCK 2. Generation is preconfigured with a 20,000 speedMASTER spindle (35 kW, 130 Nm) and offers top equipment at the best price. A tool magazine with 60 pockets and the Machine Protection Control (MPC) technology cycle are also part of the package.

Digitized production thanks to CELOS X

Ergonomic operation is also a key issue on the control side. The app-based CELOS X runs either on the modern SINUMERIK ONE from Siemens or a current TNC 7 from HEIDENHAIN. The app-based user interface and the UMATI standard create a basis for the digitized production of the future. A wide range of exclusive DMG MORI technology cycles facilitates workshop-oriented programming on the DMC 65/75 monoBLOCK 2. Generation. In addition, GREENMODE supports resource-saving production. Energy-efficient components and intelligent machine monitoring reduce energy consumption by over 30 percent, enabling the DMC 65/75 monoBLOCK 2. Generation to take a step toward more sustainable production.

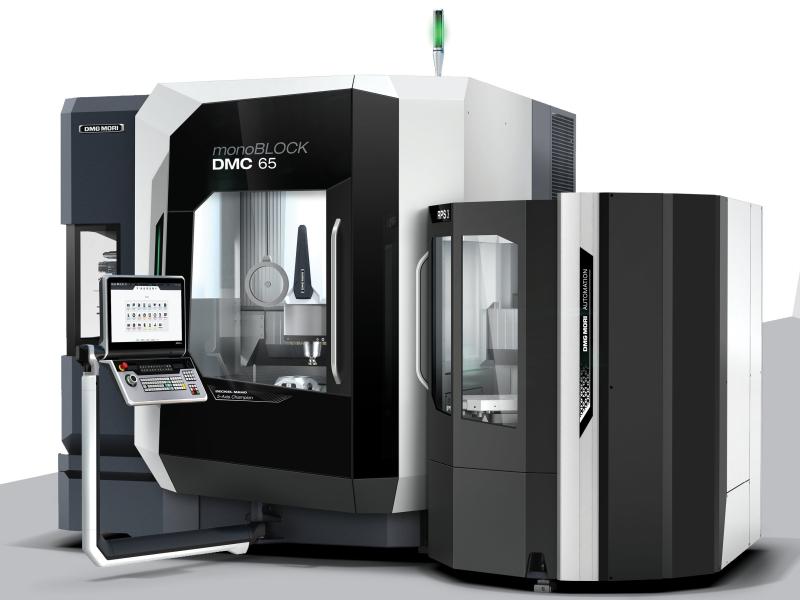

Munich. Aviation & Space, Die & Mold or Mobility - the versatility of the DMC monoBLOCK series from DMG MORI has always proven itself in numerous industries. The DMC 65 monoBLOCK 2. Generation and DMC 75 monoBLOCK 2. Generation will continue this success story. The two 5-axis simultaneous machining centers produce complex workpieces up to ø 630 x 500 mm and 600 kg on a footprint of just 8 m². The key to even more efficient machining is the integration of several processes in one clamping. The DMC 65 monoBLOCK 2. Generation combines six technologies on request: Milling, turning at up to 1,200 min-1, grinding, gear cutting, in-process measuring and Ultrasonic.

„Ready for Automation“

DMG MORI has taken the challenges of modern production into account and developed successors that work even more precisely, flexibly and economically and can be used both as a standalone variant and automated at the same time. In keeping with the motto "Ready for Automation", the work area door opens to the left, enabling perfect automation integration. The DMC series consistently implements unrestricted access to the work area, tool magazine and set-up station from the front - the only machine concept of its kind.

Depending on the application, customers can choose from a wide range of automation solutions. In addition to the RPS 3 rotary storage system or the PH Cell pallet handling system, the Robo2Go Milling workpiece handling system or the MATRIS WPH combined workpiece and pallet handling system can also be connected, depending on the application. Driverless transport systems from the AMR series are also ideal for automation.

4 µm positioning accuracy

The DMC 65/75 monoBLOCK 2. Generation is characterized by its outstanding accuracy and reliability. The 3-point support ensures optimum stability and maximum machining performance. Thanks to the stable design with a large-volume slide and 45 mm wide roller guides in all axes, excellent long-term accuracy is guaranteed.

Large ball screws with a diameter of up to 50 mm also contribute to the high precision of the machine. Extensive cooling measures in the basic machine, multi-sensor compensation, and thermosymmetrical ram cooling result in higher accuracy and better surface quality. Overall, a positioning accuracy of 4 µm is achieved, making the DMC 65/75 monoBLOCK 2. Generation an ideal choice for demanding machining tasks.

Wide range of MASTER spindles and up to 240 tools integrated into the machine

The wide range of spindles allows the DMC 65 monoBLOCK 2. Generation to be equipped for specific applications. The range extends from speeds of up to 30,000 rpm to torques of up to 200 Nm. All MASTER spindles come with a 36-month warranty with no limit on operational hours and technical availability of over 96 percent. A machine-integrated tool magazine with up to 240 pockets ensures minimal non-productive times on the

DMC 65/75 monoBLOCK 2. Generation, even in high-mix single-part and small-batch production.The DMC 75 monoBLOCK 2. Generation is preconfigured with a 20,000 speedMASTER spindle (35 kW, 130 Nm) and offers top equipment at the best price. A tool magazine with 60 pockets and the Machine Protection Control (MPC) technology cycle are also part of the package.

Digitized production thanks to CELOS X

Ergonomic operation is also a key issue on the control side. The app-based CELOS X runs either on the modern SINUMERIK ONE from Siemens or a current TNC 7 from HEIDENHAIN. The app-based user interface and the UMATI standard create a basis for the digitized production of the future. A wide range of exclusive DMG MORI technology cycles facilitates workshop-oriented programming on the DMC 65/75 monoBLOCK 2. Generation. In addition, GREENMODE supports resource-saving production. Energy-efficient components and intelligent machine monitoring reduce energy consumption by over 30 percent, enabling the DMC 65/75 monoBLOCK 2. Generation to take a step toward more sustainable production.