DMG MORI

Products

Grinding centres

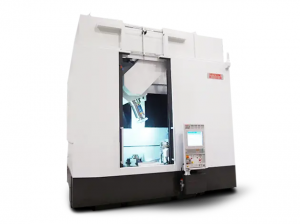

TGN 30/30

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 90 mm | |

| 20 kg | |

| 250 mm | |

| Machine characteristics |

|

| 300 mm | |

| Tool properties |

|

| 405 mm | |

| Machine control |

|

| Fanuc | |

CNC Thread Grinding Machine

High-accuracy thread grinding machine with excellent operability having distance between centers 300mm

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

Improvement in stability of pitch diameter of thread

Easier replacement of the grinding wheel and the dresser

High-accuracy thread grinding machine with excellent operability having distance between centers 300mm

- Numerical-controlled swivel of wheelhead enables helix angle change by easy numerical input.

- It provides high-accuracy thread grinding for various workpieces such as thread gauge, worm shaft, etc.

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

- Rotary encoder with 0.0001°control on work spindle, and optical scale feedback control on X & Z-axis are equipped as standard.

- By equipping built-in type grinding spindle as standard, machine vibration is minimized to achieve high-accuracy thread grinding even with small-diameter thread.

Improvement in stability of pitch diameter of thread

- Locating the dresser on the back of the work spindle enables minimizing error in X-axis travel and improves diameter accuracy.

Easier replacement of the grinding wheel and the dresser

- Easy access from a side door, and a top door available for crane operation.

TGN 30/80

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 150 mm | |

| 80 kg | |

| 750 mm | |

| Machine characteristics |

|

| 800 mm | |

| Tool properties |

|

| 455 mm | |

| Machine control |

|

| Fanuc | |

CNC Thread Grinding Machine

High-accuracy thread grinding machine with excellent operability having distance between centers 800mm

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

Improvement in stability of pitch diameter of thread

Easier replacement of the grinding wheel and the dresser

High-accuracy thread grinding machine with excellent operability having distance between centers 800mm

- Numerical-controlled swivel of wheelhead enables helix angle change by easy numerical input.

- It provides high-accuracy thread grinding for various workpieces such as spindle, worm shaft, thread gauge, ball screw, etc.

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

- Rotary encoder with 0.0001°control on work spindle, and optical scale feedback control on X & Z-axis are equipped as standard.

- By equipping built-in type grinding spindle as standard, machine vibration is minimized to achieve high-accuracy thread grinding even with small-diameter thread.

Improvement in stability of pitch diameter of thread

- Locating the dresser on the back of the work spindle enables minimizing error in X-axis travel and improves diameter accuracy.

Easier replacement of the grinding wheel and the dresser

- Easy access from a side door, and a top door available for crane operation.

TGN 45/125

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 200 mm | |

| 100 kg | |

| 1200 mm | |

| Machine characteristics |

|

| 1250 mm | |

| Tool properties |

|

| 510 mm | |

| Machine control |

|

| Fanuc | |

CNC Thread Grinding Machine

High-accuracy thread grinding machine with excellent operability having distance between centers 1250mm

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

Improvement in stability of pitch diameter of thread

Easier replacement of the grinding wheel and the dresser

High-accuracy thread grinding machine with excellent operability having distance between centers 1250mm

- Numerical-controlled swivel of wheelhead enables helix angle change by easy numerical input.

- It provides high-accuracy thread grinding for various workpieces such as spindle, worm shaft, ball screw, etc.

Closed loop positional feedback for each axis providing the highest accuracy thread grinding results

- Rotary encoder with 0.0001°control on work spindle, and optical scale feedback control on X & Z-axis are equipped as standard.

- By equipping built-in type grinding spindle as standard, machine vibration is minimized to achieve high-accuracy thread grinding even with small-diameter thread.

Improvement in stability of pitch diameter of thread

- Locating the dresser on the back of the work spindle enables minimizing error in X-axis travel and improves diameter accuracy.

Easier replacement of the grinding wheel and the dresser

- Easy access from a side door, and a top door available for crane operation.

Vertical Mate 55

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 550 mm | |

| 500 mm | |

| 450 mm | |

| 325 mm | |

| Machine characteristics |

|

| 350 min⁻¹ | |

| 15000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Multi-process grinding capability

Wheel spindle

High-accuracy result example with TAIYO's standard test piece

Other Features

Multi-process grinding capability

- Grinding ID, OD and face by one-time chucking

- ATC unit with storage capacity of 6 tools

Wheel spindle

- Single spindle type : HSK-E63

- 2-position turret with indexing angle 0° and 22.5°

High-accuracy result example with TAIYO's standard test piece

- Roundness 1.0µm

- Concentricity, Cylindricity, Squareness 2.0µm

- Surface roughness Ra 0.2µm

Other Features

- Touch sensor for measuring ID, OD and face (option)

- Scale feedback control for X-axis (One for Z-axis available as an option)

- Single point dresser (Rotary dresser available as an option)

- Work spindle fixed-position stop

Vertical Mate 85

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 850 mm | |

| 800 mm | |

| 600 mm | |

| 500 mm | |

| Machine characteristics |

|

| 200 min⁻¹ | |

| 9000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Multi-process grinding capability

Wheel spindle

High-accuracy result example with TAIYO's standard test piece

Other Features

Multi-process grinding capability

- Grinding ID, OD and face by one-time chucking

- ATC unit with storage capacity of 6 tools

Wheel spindle

- Single spindle type : HSK-E100

- 2-position turret with indexing angle 0° and 22.5°

High-accuracy result example with TAIYO's standard test piece

- Roundness 1.0µm

- Concentricity, Cylindricity, Squareness 2.0µm

- Surface roughness Ra 0.2µm

Other Features

- Touch sensor for measuring ID, OD and face (option)

- Scale feedback control for X-axis (One for Z-axis available as an option)

- Single point dresser (Rotary dresser available as an option)

- Work spindle fixed-position stop

Vertical Mate 125

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 1250 mm | |

| 1200 mm | |

| 600 mm | |

| 500 mm | |

| Machine characteristics |

|

| 100 min⁻¹ | |

| 9000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Multi-process grinding capability

Wheel spindle

Other Features

Multi-process grinding capability

- Grinding ID, OD and face by one-time chucking

- ATC unit with storage capacity of 6 tools

Wheel spindle

- Single spindle type : HSK-E100

- 2-position turret with indexing angle 0° and 22.5°

- Roundness, Concentricity, Cylindricity, Squareness 2.0µm

- Surface roughness Ra 0.2µm

Other Features

- Touch sensor for measuring ID, OD and face (option)

- Scale feedback control for X-axis (One for Z-axis available as an option)

- Single point dresser (Rotary dresser available as an option)

- Work spindle fixed-position stop

CVG 6

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 650 mm | |

| 600 mm | |

| 550 mm | |

| 500 mm | |

| Machine characteristics |

|

| 350 min⁻¹ | |

| 9000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

2-Pallet APC (Auto. Pallet Change) option

Wheel spindle B-axis option

Work spindle C-axis option

Other features

2-Pallet APC (Auto. Pallet Change) option

- Reduction of non-grinding time by allowing workpiece change and set-up during grinding operation.

- Significant improvement of productivity by making unattended operation time longer.

- Work spindle swing φ650 mm / Table size φ550 mm

Wheel spindle B-axis option

- Standard is turret type with 3-position indexing at 0° / 22.5° / 180°.

- Turret type with continuous indexing function can be selected as an option. Minimum indexing unit is 0.0001°, between the range of ±30° for ID spindle, ±45° for OD spindle.

Work spindle C-axis option

- Continuous indexing of work spindle is available by equipping Direct Drive motor, at minimum indexing unit 0.0001°.

- Allows profile grinding of curvic coupling and cam shape, etc.

Other features

- ATC unit with 6-tool storage for internal grinding spindle

- Touch sensor for measuring ID, OD and face (option)

- Rotary dresser (Single point dresser available as an option)

- Linear scale for X-axis (One for Z-axis available as an option)

CVG 9

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 950 mm | |

| 900 mm | |

| 700 mm | |

| 600 mm | |

| Machine characteristics |

|

| 250 min⁻¹ | |

| 9000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

2-Pallet APC (Auto. Pallet Change) option

Wheel spindle B-axis option

Work spindle C-axis option

Other features

2-Pallet APC (Auto. Pallet Change) option

- Reduction of non-grinding time by allowing workpiece change and set-up during grinding operation.

- Significant improvement of productivity by making unattended operation time longer.

- Work spindle swing φ950 mm / Table size φ850 mm

Wheel spindle B-axis option

- Standard is turret type with 3-position indexing at 0° / 22.5° / 180°.

- Turret type with continuous indexing function can be selected as an option. Minimum indexing unit is 0.0001°, between the range of ±30° for ID spindle, ±45° for OD spindle.

Work spindle C-axis option

- Continuous indexing of work spindle is available by equipping Direct Drive motor, at minimum indexing unit 0.0001°.

- Allows profile grinding of curvic coupling and cam shape, etc.

Other features

- ATC unit with 6-tool storage for internal grinding spindle

- Touch sensor for measuring ID, OD and face (option)

- Rotary dresser (Single point dresser available as an option)

- Linear scale for X-axis (One for Z-axis available as an option)

CVG 13

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 1350 mm | |

| 1300 mm | |

| 700 mm | |

| 600 mm | |

| Machine characteristics |

|

| 100 min⁻¹ | |

| 9000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

2-Pallet APC (Auto. Pallet Change) option

Wheel spindle B-axis option

Work spindle C-axis option

Other features

2-Pallet APC (Auto. Pallet Change) option

- Reduction of non-grinding time by allowing workpiece change and set-up during grinding operation.

- Significant improvement of productivity by making unattended operation time longer.

- Work spindle swing ø1350 mm / Table size ø1250 mm

Wheel spindle B-axis option

- Standard is turret type with 3-position indexing at 0° / 22.5° / 180°.

- Turret type with continuous indexing function can be selected as an option. Minimum indexing unit is 0.0001°, between the range of ±30° for ID spindle, ±45° for OD spindle.

Work spindle C-axis option

- Continuous indexing of work spindle is available by equipping Direct Drive motor, at minimum indexing unit 0.0001°.

- Allows profile grinding of curvic coupling and cam shape, etc.

Other features

- ATC unit with 6-tool storage for internal grinding spindle

- Touch sensor for measuring ID, OD and face (option)

- Rotary dresser (Single point dresser available as an option)

- Linear scale for X-axis (One for Z-axis available as an option)

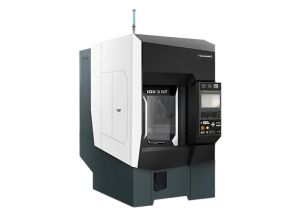

NVGH-3T

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 350 mm | |

| 350 mm | |

| 450 mm | |

| 320 mm | |

| Machine characteristics |

|

| 800 min⁻¹ | |

| 20000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

Excellent grinding performance by ultimate high-rigidity model

High-rigidity grinding spindle

Work spindle C-axis option

Other features

- Highest spec model for small/medium parts to improve productivity and to achieve high accuracy in various industries such as automobile, aircrafts, bearings, etc.

High-rigidity grinding spindle

- 2 spindles equipped on a turret with continuous indexing function (B-axis)

- Internal grinding spindle : HSK-A63 with ATC function

- External grinding spindle : φ355 grinding wheel equipped as standard

Work spindle C-axis option

- Continuous indexing of work spindle is available at minimum indexing unit 0.0001? by equipping Direct Drive motor

- Enables non-round grinding such as polygon and cam shape, and also curvic coupling by synchronous control of X and C-axis

Other features

- Automation with SCARA robot, rotary stocker, etc.

- AMS (Automatic Measurement System) available with various stylus options

- ATC (Automatic Tool Changer) with 6-tool storage for internal grinding spindle

- Dresser unit with single point diamond (Options: Rotary dresser, R-shape dresser, AE sensor, etc.)

NVGH-6T

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 650 mm | |

| 600 mm | |

| 500 mm | |

| 450 mm | |

| Machine characteristics |

|

| 500 min⁻¹ | |

| 10000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Excellent grinding performance by ultimate high-rigidity model

Hard turning function (option)

Work spindle C-axis function (option)

Other features

Excellent grinding performance by ultimate high-rigidity model

- Highest spec model to improve productivity and to achieve high accuracy in various industries such as bearings, aircrafts, industrial machinery, etc.

- 2 high-rigidity grinding spindles are equipped on a turret with continuous indexing function (B-axis); internal grinding spindle with HSK-A100, and external grinding spindle.

Hard turning function (option)

- External grinding spindle can be changed to turning spindle for high-efficiency stock removal, which contributes to significant reduction of cycle time.

Work spindle C-axis function (option)

- Continuous indexing of work spindle is available at minimum indexing unit 0.0001? by equipping Direct Drive motor

- Enables non-round grinding such as polygon and cam shape, and also curvic coupling by synchronous control of X and C-axis

Other features

- Automation with SCARA robot, rotary stocker, APC (Automatic Pallet Changer), etc.

- AMS (Automatic Measurement System) available with various stylus options

- ATC (Automatic Tool Changer) with 6-tool storage for internal grinding spindle

- Dresser unit with single point diamond (Options: Rotary dresser, R-shape dresser, AE sensor, etc.)

NVGH-9T

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 950 mm | |

| 900 mm | |

| 700 mm | |

| 600 mm | |

| Machine characteristics |

|

| 250 min⁻¹ | |

| 6000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Excellent grinding performance by ultimate high-rigidity model

Hard turning function (option)

Work spindle C-axis option

Other features

Excellent grinding performance by ultimate high-rigidity model

- Highest spec model to improve productivity and to achieve high accuracy in various industries such as bearings, aircrafts, ships, energy, industrial machinery, etc.

- 1-spindle spec. with HSK-A125 high-rigidity grinding spindle equipped on a turret with continuous indexing function (B-axis)

Hard turning function (option)

- Turning spindle can be added as an option for high-efficiency stock removal, which contributes to significant reduction of cycle time.

Work spindle C-axis option

- Continuous indexing of work spindle is available at minimum indexing unit 0.0001? by equipping Direct Drive motor

- Enables non-round grinding such as polygon and cam shape, and also curvic coupling by synchronous control of X and C-axis

Other features

- Automation with SCARA robot, rotary stocker, APC (Automatic Pallet Changer), etc.

- AMS (Automatic Measurement System) available with various stylus options

- ATC (Automatic Tool Changer) with 8-tool storage for internal grinding spindle

- Dresser unit with single point diamond (Options: Rotary dresser, R-shape dresser, AE sensor, etc.)

NVGH-12T

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 1250 mm | |

| 1200 mm | |

| 700 mm | |

| 600 mm | |

| Machine characteristics |

|

| 200 min⁻¹ | |

| 6000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Excellent grinding performance by ultimate high-rigidity model

Hard turning function (option)

Work spindle C-axis option

Other features

Excellent grinding performance by ultimate high-rigidity model

- Highest spec model to improve productivity and to achieve high accuracy in various industries such as bearings, aircrafts, ships, energy, industrial machinery, etc.

- 1-spindle spec. with HSK-A125 high-rigidity grinding spindle equipped on a turret with continuous indexing function (B-axis)

Hard turning function (option)

- Turning spindle can be added as an option for high-efficiency stock removal, which contributes to significant reduction of cycle time.

Work spindle C-axis option

- Continuous indexing of work spindle is available at minimum indexing unit 0.0001? by equipping Direct Drive motor

- Enables non-round grinding such as polygon and cam shape, and also curvic coupling by synchronous control of X and C-axis

Other features

- Automation with SCARA robot, rotary stocker, APC (Automatic Pallet Changer), etc.

- AMS (Automatic Measurement System) available with various stylus options

- ATC (Automatic Tool Changer) with 8-tool storage for internal grinding spindle

- Dresser unit with single point diamond (Options: Rotary dresser, R-shape dresser, AE sensor, etc.)

NVGH-22T

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 2250 mm | |

| 2200 mm | |

| 700 mm | |

| 600 mm | |

| Machine characteristics |

|

| 100 min⁻¹ | |

| 6000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Excellent grinding performance by ultimate high-rigidity model

Hard turning function (option)

Work spindle C-axis option

Other features

Excellent grinding performance by ultimate high-rigidity model

- Highest spec model to improve productivity and to achieve high accuracy in various industries such as bearings, aircrafts, ships, energy, industrial machinery, etc.

- 1-spindle spec. with HSK-A125 high-rigidity grinding spindle equipped on a turret with continuous indexing function (B-axis)

Hard turning function (option)

- Turning spindle can be added as an option for high-efficiency stock removal, which contributes to significant reduction of cycle time.

Work spindle C-axis option

- Continuous indexing of work spindle is available at minimum indexing unit 0.0001? by equipping Direct Drive motor

- Enables non-round grinding such as polygon and cam shape, and also curvic coupling by synchronous control of X and C-axis

Other features

- Automation with SCARA robot, rotary stocker, APC (Automatic Pallet Changer), etc.

- AMS (Automatic Measurement System) available with various stylus options

- ATC (Automatic Tool Changer) with 8-tool storage for internal grinding spindle

- Dresser unit with single point diamond (Options: Rotary dresser, R-shape dresser, AE sensor, etc.)

IGV-1N

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 200 mm | |

| 100 mm | |

| 200 mm | |

| 100 mm | |

| Machine characteristics |

|

| 2000 min⁻¹ | |

| 75000 min⁻¹ | |

CNC Vertical Internal Grinding Machine

Operability improved by its vertical structure

Suitable for mass production of precision parts

Space-saving feature

Other features

Operability improved by its vertical structure

- Easy workpiece setup and centering with both hands

- Stable workpiece seating on a chuck with less clamping force

- Roundness of less than 1µm achieved with Taiyo Koki's standard test piece

Suitable for mass production of precision parts

- A variety of grinding spindles available, 45,000min-1 or 75,000min-1 as standard, 30,000min-1 selectable as an option

- In-process ID measuring gauge available as an option

Space-saving feature

- Minimized installation space with machine width 1,100mm x depth 2,800mm

Other features

- Automation systems available such as robot, loader, stocker, etc (option)

- Chucking systems available such as precision air chuck, diaphragm chuck, collet chuck, etc (option)

- Automatic measurement system (option)

- Scale feedback control for X/Z-axis (option)

- Single point dresser (Rotary dresser and AE dresser available as an option)

IGV-3N

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 380 mm | |

| 250 mm | |

| 300 mm | |

| 150 mm | |

| Machine characteristics |

|

| 800 min⁻¹ | |

| 18000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Internal Grinding Machine

Operability improved by its vertical structure

Suitable for mass production of precision parts

Space-saving feature

Other features

Operability improved by its vertical structure

- Easy workpiece setup and centering with both hands

- Stable workpiece seating on a chuck with less clamping force

- Roundness of less than 1µm achieved with Taiyo Koki's standard test piece

Suitable for mass production of precision parts

- ATC (Automatic Tool Changer) available as an option with storage capacity of 5 tools

- A variety of grinding spindles available, 18,000min-1 as standard, 30,000min-1, 45,000min-1 or 75,000min-1 selectable as an option

- In-process ID measuring gauge available as an option

Space-saving feature

- Minimized installation space with machine width 1,400mm (1,530 at ATC spec) x depth 3,050mm

Other features

- Automation systems available such as robot, loader, stocker, etc (option)

- Chucking systems available such as precision air chuck, scroll chuck, magnet chuck, etc (option)

- Automatic measurement system (option)

- Scale feedback control for X/Z-axis (option)

- Single point dresser (Rotary dresser and AE dresser available as an option)

EGV-3N

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 380 mm | |

| 300 mm | |

| 300 mm | |

| 150 mm | |

| Machine characteristics |

|

| 800 min⁻¹ | |

| 3700 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical External Grinding Machine

Operability improved by its vertical structure

Suitable for mass production of precision parts

Space-saving feature

Other features

Operability improved by its vertical structure

- Easy workpiece setup and centering with both hands

- Stable workpiece seating on a chuck with less clamping force

- Roundness of less than 1µm achieved with Taiyo Koki's standard test piece

Suitable for mass production of precision parts

- Grinding spindle with rotation speed 3,700min-1

- In-process OD measuring gauge available as an option

Space-saving feature

- Minimized installation space with machine width 1,400mm x depth 3,050mm

Other features

- Automation systems available such as robot, loader, stocker, etc (option)

- Chucking systems available such as precision air chuck, scroll chuck, magnet chuck, etc (option)

- Automatic measurement system (option)

- Scale feedback control for X/Z-axis (option)

- Single point dresser (Rotary dresser and AE dresser available as an option)

IGV-1NT

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 180 mm | |

| 100 mm | |

| 100 mm | |

| 100 mm | |

| Machine characteristics |

|

| 2000 min⁻¹ | |

| 75000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Operability improved by its vertical structure

Multi-process grinding enabled by turret-type wheel head

High productivity in a compact installation space

Other features

Operability improved by its vertical structure

- Easy workpiece setup and centering with both hands

- Stable workpiece seating on a chuck with less clamping force

- Roundness of less than 1µm achieved with Taiyo Koki's standard test piece

Multi-process grinding enabled by turret-type wheel head

- Both internal and external grinding spindles equipped as standard, which enables grinding of ID, OD and face in one-time chucking

- Internal grinding spindle : selectable from 30,000min-1, 45,000min-1 or 75,000min-1

- External grinding spindle : 3,700min-1

High productivity in a compact installation space

- Minimized installation space with machine width 1,190mm x depth 3,100mm

- Suitable for high-accuracy, high-efficiency grinding of mass-produced precision parts

Other features

- Automation systems available such as robot, loader, stocker, etc. (option)

- Chucking systems available such as precision air chuck, diaphragm chuck, collet chuck, etc. (option)

- Automatic measurement system (option)

- Scale feedback control for X/Z-axis (option)

- Single point dresser (Rotary dresser and AE dresser available as an option)

IGV-3NT

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 300 mm | |

| 200 mm | |

| 150 mm | |

| 150 mm | |

| Machine characteristics |

|

| 800 min⁻¹ | |

| 75000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Operability improved by its vertical structure

Multi-process grinding enabled by turret-type wheel head

High productivity in a compact installation space

Other features

Operability improved by its vertical structure

- Easy workpiece setup and centering with both hands

- Stable workpiece seating on a chuck with less clamping force

- Roundness of less than 1µm achieved with Taiyo Koki's standard test piece

Multi-process grinding enabled by turret-type wheel head

- Both internal and external grinding spindles equipped as standard, which enables grinding of ID, OD and face in one-time chucking

- Internal grinding spindle : selectable from 30,000min-1, 45,000min-1 or 75,000min-1

- External grinding spindle : 3,700min-1

High productivity in a compact installation space

- Minimized installation space with machine width 1,570mm x depth 3,250mm

- Suitable for high-accuracy, high-efficiency grinding of mass-produced precision parts

Other features

- Touch panel with a wide display for smooth operation

- Conversational programming software "GriPS?" available as an option

- Automation systems available such as robot, loader, stocker, etc (option)

- Automatic measurement system (option)

- Chucking systems available such as precision air chuck, collet chuck, diaphragm chuck, etc (option)

PGV 2

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 250 mm | |

| 200 mm | |

| 200 mm | |

| 200 mm | |

| Machine characteristics |

|

| 1500 min⁻¹ | |

| 18000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

High productivity enabled by turn table

Reduction of cycle time with 2-ACC (Auto. Chuck Change) system

Wheel spindle combination

Space-saving feature

Other features

Reduction of cycle time with 2-ACC (Auto. Chuck Change) system

- A work loading/unloading station and 1 grinding station is equipped as standard, which significantly improves production capacity.

- Work change and set-up can be done while grinding another work.

- Different processes can be done by selecting gang-tooling spec.

Wheel spindle combination

- Standard : 1 spindle (Internal or External)

- Option 1 : 2 spindles (Internal + Internal)

- Option 2 : 2 spindles (Internal + External)

Space-saving feature

- With its multi-processing capability, floor space and labor cost is less than half compared to having an ID grinder and an OD grinder separately.

Other features

- Auto. measuring system (option)

- Single point dresser (Rotary dresser available as an option)

- Scale feedback control for X and Z-axis (option)

PGV 3

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 250 mm | |

| 150 mm | |

| 120 mm | |

| 120 mm | |

| Machine characteristics |

|

| 1500 min⁻¹ | |

| 45000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

High-production CNC Vertical Grinding Machine

Reduction of cycle time with 3-ACC (Auto. Chuck Change) system

Wheel spindle combination

Space-saving feature

Other features

Reduction of cycle time with 3-ACC (Auto. Chuck Change) system

- A work loading/unloading station and 2 grinding stations are equipped as standard, which significantly improves production capacity.

- Work change and set-up can be done while grinding other 2 works.

- Different processes can be done in 2 grinding stations at the same time.

Wheel spindle combination

- Standard : 2 spindles (Internal + External)

- Option 1 : 2 spindles (Internal + Internal)

- Option 2 : 3 spindles (Gang tooling spec) Internal (Grinding ST.1) + Internal & External (Grinding ST.2)

Space-saving feature

- With its multi-processing capability, floor space and labor cost is less than half compared to having an ID grinder and an OD grinder separately.

Other features

- Auto. measuring system (option)

- Single point dresser (Rotary dresser available as an option)

- Scale feedback control for X and Z-axis (option)

NVG-7LH

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 750 mm | |

| 750 mm | |

| 1100 mm | |

| 1000 mm | |

| Machine characteristics |

|

| 200 min⁻¹ | |

| 6000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

Special model dedicated to deep hole grinding

Special model dedicated to deep hole grinding

Easy setup and high accuracy enabled by the vertical structure

Optimal solution for major parts for construction machinery

Heat-resistant measures at each section allowing high-accuracy grinding

Special model dedicated to deep hole grinding

- Deep hole spindle is equipped as standard for grinding long workpiece up to ø750mm(29.5in) x H1,100mm(43.3in).

- A variety of deep hole spindle is available to meet customer's demands.

Easy setup and high accuracy enabled by the vertical structure

- Setup work that doesn't go against the gravity allows you to perform centering much more easily and safely.

- In addition to grinding without being affected by gravity, easy delivery of coolant to the grinding point also contributes to accuracy improvement of deep-hole ID such as roundness, concentricity, cylindricity, surface roughness, etc.

Optimal solution for major parts for construction machinery

- A typical example is hydraulic breaker cylinder for rock breaker. The piston inside of the cylinder moves up and down by hydraulic pressure, where the accuracy of cylinder ID directly affects the smooth piston movement and boosts the power of the rock breaker.

Heat-resistant measures at each section allowing high-accuracy grinding

- 0.1µm-scale feedback control is equipped on both X and Z-axis, which eliminates accuracy errors caused by elongation of ball screws. Also, there is an air gap between the bed and the oil pan to avoid heat effect from the coolant to the bed.

NVG-12LH

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 1150 mm | |

| 1150 mm | |

| 1300 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 90 min⁻¹ | |

| 6000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

Special model dedicated to deep hole grinding

Special model dedicated to deep hole grinding

Special model dedicated to deep hole grinding

- Deep hole spindle is equipped as standard for grinding long workpiece up to ø1,150mm(45.2in) x H1,300mm(51.1in).

- A variety of deep hole spindle is available to meet customer's demands.

- Setup work that doesn't go against the gravity allows you to perform centering much more easily and safely.

- In addition to grinding without being affected by gravity, easy delivery of coolant to the grinding point also contributes to accuracy improvement of deep-hole ID such as roundness, concentricity, cylindricity, surface roughness, etc.

- A typical example is hydraulic breaker cylinder for rock breaker. The piston inside of the cylinder moves up and down by hydraulic pressure, where the accuracy of cylinder ID directly affects the smooth piston movement and boosts the power of the rock breaker.

- 0.1µm-scale feedback control is equipped on both X and Z-axis, which eliminates accuracy errors caused by elongation of ball screws. Also, there is an air gap between the bed and the oil pan to avoid heat effect from the coolant to the bed.

Vertical Mate 35

|

Grinding centre

DMG MORI Global Marketing GmbH

Grinding centres

| Workspace |

|

| 350 mm | |

| 350 mm | |

| 350 mm | |

| 250 mm | |

| Machine characteristics |

|

| 500 min⁻¹ | |

| 18000 min⁻¹ | |

| Machine control |

|

| Fanuc | |

CNC Vertical Multi-Process Grinding Machine

Multi-process grinding capability

Wheel spindle

High-accuracy result example with TAIYO's standard test piece

Other Features

Multi-process grinding capability

- Grinding ID, OD and face by one-time chucking

- ATC unit with storage capacity of 4 tools

Wheel spindle

- Single spindle type : HSK-E63

- 2-position turret with indexing angle 0° and 22.5°

High-accuracy result example with TAIYO's standard test piece

- Roundness 1.0µm

- Concentricity, Cylindricity, Squareness 2.0µm

- Surface roughness Ra 0.2µm

Other Features

- Touch sensor for measuring ID, OD and face (option)

- Scale feedback control for X-axis (One for Z-axis available as an option)

- Single point dresser (Rotary dresser available as an option)

- Work spindle fixed-position stop

Loading ...