An optimized VarioSpeedDresser for even finer gear surfaces, laser-finished diamond dressing gear wheels of an extraordinary cutting performance and splitting quality, powerful solutions for highly precise honing of parts with internal gearing and much more. DVS Tooling, the DVS TECHNOLOGY GROUP’s company dedicated to tools and technology support for PRÄWEMA gear honing is extending its portfolio with many novelties and advancements to again underline its global innovation and technology leadership.

Established in 2015, DVS Tooling GmbH has since been adding significant value to the products of gearbox manufactures and their suppliers by providing original tooling solutions and international technology support for PRÄWEMA gear honing, the world’s leading method for optimizing geared surfaces. The successful portfolio covering the entire range of PRÄWEMA gear honing tools so far includes the PRÄWEMA ORIGINAL-series dual-zone honing rings with optimized damping as well as the VarioSpeedDresser dressing tool, VSD for short, optimized using the DVS LaserCut finishing method designed for this very purpose. The DVS company's thorough engineering efforts dedicated to materials and production processes once again enhance the performance of both product lines, i.e. honing rings and VSD. To supplement the established dual-zone honing ring qualities mentioned above, DVS Tooling now presents ECODUR 636, a new honing ring material specifically designed for applications requiring an extraordinary cutting performance. Pores which are systematically added to the cutting material help to efficiently remove and dissipate chips in a controlled manner without clogging up the surface. ECODUR 636 thereby guarantees optimized machining results even in honing processes that generate extreme thermal loads or provide limited possibilities of intervention and very difficult chip removal. On top of the above, DVS Tooling supplies the ideal original tool specifically designed for PRÄWEMA gear honing machines equipped with a new honing head for machining larger gear wheels and gear shafts with a diameter of 400 mm: All previous 270 mm diameter honing ring qualities – including the new ECODUR 636 – are now available with a diameter of 400 mm.

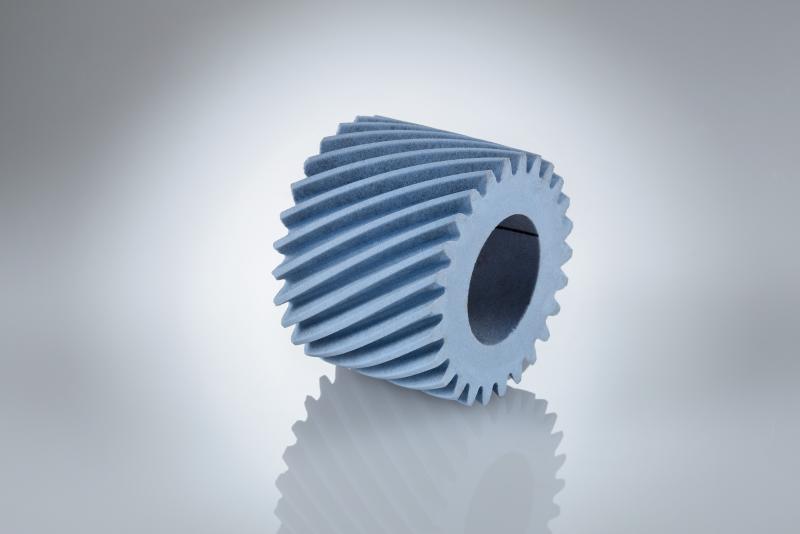

VSD SF dressing tool for even more finely machined gear surfaces

The DVS tool specialist has extended its successful VSD dressing tool range with the trend-setting "VSD SF" model. "SF" in this case stands for "Superfinishing" to designate the extremely high and again optimized surface quality which is first transferred to the honing ring by the dressing process and then to the gearing by the eventual honing process. By developing VarioCrossHoning technology – an oscillating method as part of the honing process – DVS affiliate PRÄWEMA Antriebstechnik is now able to adequately respond to the gearbox manufacturers’ demand for even more finely machined gear surfaces. What it takes to translate this technology into reliable and constant large-volume production is to appropriately condition the relevant tools. VSD SF now enables DVS Tooling to premiere not only dressing tools that meet very strict production tolerance requirements but also to produce a surface roughness of Rz < 1 µm for for external gears. In order to live up to its claim of being a supplier of integrated tooling systems designed for the PRÄWEMA gear honing, the DVS company has now further expanded its product portfolio with powerful diamond dressing gear wheels, as not all of the global database of mainly older PRÄWEMA honing machines are using the comparatively new VSD dressing technology. Product design in this case was particularly focused on optimizing and adapting the properties of conventional diamond dressing wheels to the stricter requirements of modern honing processes. This was achieved by adopting the proprietary DVS LaserCut finishing technology previously used for successfully optimizing the VSD products: Whereas conventional diamond dressing gear wheels from many competitors are extremely finely polished and therefore have a fairly blunt diamond surface, the laser-refined rotary diamond dressers supplied by DVS Tooling feature well-defined micro-cutting edges. They are therefore marked by an outstanding performance and splitting quality which makes the dressing process inside the honing machine a lot more efficient. Another benefit is that they generate much lower load forces during the dressing process which extends tool life and reduces operator's tooling costs.

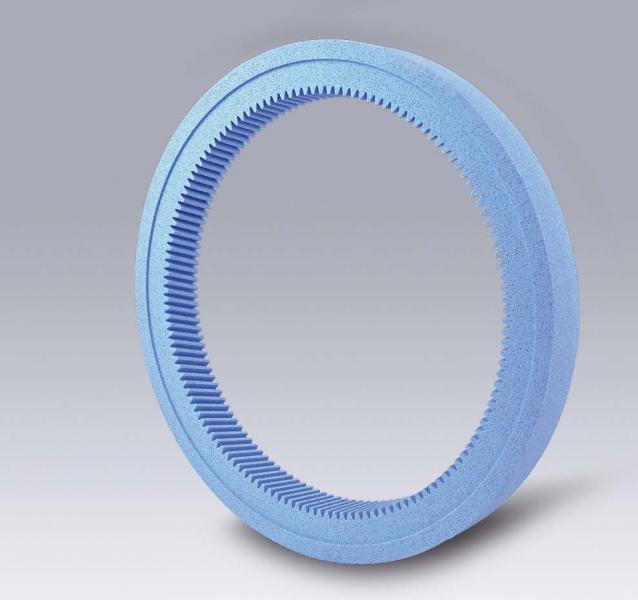

Powerful tooling solutions for honing parts with internal gears

Having said this, DVS Tooling not only offers custom-fit tooling solutions for the well-known honing of external gearings but is now also providing tools for optimizing internal gearings of any geometry, such as the ones of rings gears needed e.g. for electric drives. These products particularly include newly engineered honing wheels with external gears and VSD dressing tools with internal gears. As opposed to honing rings with internal gears, developing the former was faced with particular challenges since the ratio of workpiece and tool surfaces is notoriously tending to shift towards the workpiece surface. Achieving a honing wheel life still within the user’s economic feasibility range therefore required the use of a suitable composition of materials which firstly had to be developed. Relying on ideally adapted cutting materials and innovative bonding systems obtained from close cooperation with NAXOS-DISKUS Schleifmittelwerke, the DVS grinding tool specialist, DVS Tooling is now able to offer superior tooling solutions for the high-precision honing of parts with internal gears. Ever since its establishment, DVS Tooling has supplemented its portfolio of products for users of PRÄWEMA gear honing machines with technology support services. A global team of highly qualified application engineers and product managers provide process analyses and process optimizations, technology seminars and user training as well as other services for enhanced process efficiency and customer value. These services as well as the tool portfolio for PRÄWEMA gear honing constantly extended by innovative advancements and new designs are the means by which DVS Tooling keeps setting the scale for surface and profile quality of gearbox components with both internal and external gears.

Contact:

Mr. Marc Hain

DVS TECHNOLOGY GROUP / DISKUS WERKE AG

Johannes-Gutenberg-Straße 1

D-63128 Dietzenbach

[email protected]

Germany

Germany