DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

DVS TECHNOLOGY GROUP

Gear cutting centres

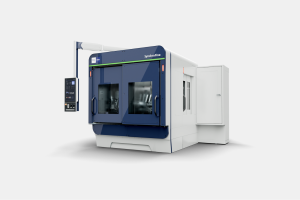

PRÄWEMA SynchroSkiver

Through a combined use of the technologies deburring, tapering, backing as well as the high efficient gear cutting method Power Skiving in one machine, the new PRÄWEMA SynchroSkiver offers users new dimensions for cycle times. Two newly developed 5-axis milling towers and an optimised gear cutting module for use of the highly efficient Power Skiving technology are at the heart of the new machine. Ideally suited for synchronous parts of vehicle gearboxes such as sliding couplings, most of the green machining of the workpiece can now be done in only one single clamping. Depending on the requirement, further machining modules and a wide range of different automation solutions can be added. Short travel paths permit short cycle times. This is achieved by means of central loading via a transport shuttle and machining units set out to the right and left of this. Alternatively and for even more output, the PRÄWEMA machine can be equipped with a second workpiece spindle.

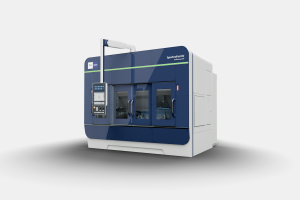

Präwema SynchroFine

|

Gear cutting centre

DVS TECHNOLOGY GROUP

Gear cutting centres

| 225 mm |

What makes SynchroFine unique is the compact design of all units. All units are mounted on a natural granite bed for optimal thermal and vibration-damping characteristics.

The digital and directly driven tool and workpiece spindles guarantee backlash-free drive and load reversal, as there is no need for mechanical transmission elements, such as toothed belts, gears, etc.

The machine is designed as a self-loading unit (pick-up principle) and is basically equipped with integrated handling units. The components can be fed individually. From simple manual loading through automation solutions with conveyor belts to robot cells with integrated camera functions from our sister company rbc robotics, we can use a wide range of automations according to your preferences and needs.

For even more efficiency, we can equip the system with two workpiece spindles in order to reduce non-productive times to a minimum.

The digital recording of operating parameters is also standard with the SynchroFine. It can be further expanded through various modules in order to analyze process data and thus continuously optimize processes

Highlights:

01

Optimized tool costs through flexible VSD dressing strategy

02

Sophisticated process reliability with short cycle times

03

Ultra-fine surfaces

04

Interlock free hard-fine machining

The digital and directly driven tool and workpiece spindles guarantee backlash-free drive and load reversal, as there is no need for mechanical transmission elements, such as toothed belts, gears, etc.

The machine is designed as a self-loading unit (pick-up principle) and is basically equipped with integrated handling units. The components can be fed individually. From simple manual loading through automation solutions with conveyor belts to robot cells with integrated camera functions from our sister company rbc robotics, we can use a wide range of automations according to your preferences and needs.

For even more efficiency, we can equip the system with two workpiece spindles in order to reduce non-productive times to a minimum.

The digital recording of operating parameters is also standard with the SynchroFine. It can be further expanded through various modules in order to analyze process data and thus continuously optimize processes

Highlights:

01

Optimized tool costs through flexible VSD dressing strategy

02

Sophisticated process reliability with short cycle times

03

Ultra-fine surfaces

04

Interlock free hard-fine machining

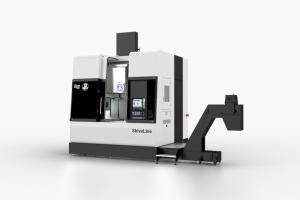

PITTLER SkiveLIne 315-1250

|

Universal machining centre

DVS TECHNOLOGY GROUP

Gear cutting centres

| Machine characteristics |

|

| 16000 kg | |

| 1250 mm | |

| 800 mm |

The PITTLER SkiveLine is a new type of skiving center with automation cell for complete machining of larger components up to a diameter of 1250mm. Based on the proven PITTLER vertical series, the new platform is geared to PITTLER's advanced Power Skiving gear cutting technology, which allows components to be skived both internally and externally. Components, such as the internal gears of the planetary gear, which are increasingly being used in future drives, can thus either be machined completely in one clamping operation or, in addition to gear cutting, be machined with upstream or downstream turning, milling or deburring processes. The PITTLER skiving center has also been optimized for fully automated series production: &Uml;via an innovative automation cell, the workspaces of up to two gear cutting centers are automatically supplied with workpieces, which minimizes space and investment requirements compared to robotic loading. In contrast to sequential machining on several machines, it is thus possible to respond economically to varying batch sizes. Translated with DeepL

Highlights:

01

6-axis – Complete internal and external machining: turning, milling, drilling, skiving, deburring, measuring, sharpening, backing, impact notching

02

Flexible automation: crane or manual loading, robot loading, optional shuttle loading and PITTLER automation cell

03

Automatic tool change through 16-part disk magazine

04

Secondary processing -> Pairs of machines

Highlights:

01

6-axis – Complete internal and external machining: turning, milling, drilling, skiving, deburring, measuring, sharpening, backing, impact notching

02

Flexible automation: crane or manual loading, robot loading, optional shuttle loading and PITTLER automation cell

03

Automatic tool change through 16-part disk magazine

04

Secondary processing -> Pairs of machines

PRÄWEMA SynchroForm (V)

|

Gear hobbing machine

DVS TECHNOLOGY GROUP

Gear cutting centres

The modular design of the SynchroForm V machine allows it to be adapted for the production of geared drive components. Set up as a single or twin spindle machine, it excels in series production with extremely profitable cycle times and high-precision machining results. Efficient complete machining in all areas of gearing in soft and hard fine machining can be achieved using the various technology modules. Your advantage: Versatile range of technologies for precise soft and hard fine machining Equipped with either one or two workpiece spindles to match unit requirements Efficient complete gearing machining of drive components