DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

DVS TECHNOLOGY GROUP

Universal machining centres

DVS ModuLine

The ModuLine component rings in a new age of production planning. Due to the high configurability of this innovative concept, it is now possible to define the optimum solution for every production process, a concept which is variable and configurable to the maximum degree, and therefore absolutely reliable and viable for the future. Due to the generous multi-technology platform, up to 4 technology modules can be integrated at the same time for efficient simultaneous and complete machining. A wide selection of high-performance pick-up spindles are also available, depending on the intended machining process. The ModuLine automation cell can be adapted to every aspect of production. Feed,linking, transport, parallel post-process activities and parts storage can be combined in the smallest possible area, depending on workpieces and the installed logistics. This represents an alternative to bulky, rigid belt linkages and inaccessible gantries.

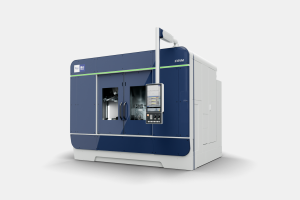

BUDERUS 235VM & VH

|

Hard-fine machining centre

DVS TECHNOLOGY GROUP

Grinding centres

| Workspace |

|

| 340 mm | |

| 250 mm | |

| 700 mm | |

Buderus Schleiftechnik GmbH has developed an innovative machine platform for the high-precision machining of rotationally symmetrical axes with a diameter of up to 300 mm and a length of 1,000 mm so that its customers can meet the requirements for maximum quality, low unit costs and maximum adaptability in equal measure.000 mm: the 235VH.

The machines enable both combined and simultaneous machining processes. The flexible configuration options allow a wide range of machining technologies from grinding, hard turning and honing to the use of driven tools. This means that the 235VH can also achieve the shortest possible routing and machining times.

Buderus is also the specialist in the use of center drive technology. Our latest development is the center drive machine 235VM with an advanced drive head. This new head achieves a working speed of up to 2,500 rpm and therefore also enables the hard turning of components. The innovative machine platform of the 235 VM is specially designed for machining rotationally symmetrical workpieces with a workpiece diameter of up to 80 mm and a length of up to 450 mm. The 235 VM enables both combined and simultaneous machining processes using a center drive.

The major advantage of center drive technology is the ability to machine internal and external geometries in just one clamping operation, which has a positive effect on both the precision of the machining process and significantly increases its efficiency.

Highlights:

01

The unique sustainable machine bed made of natural granite ensures high process stability thanks to maximum rigidity, vibration damping and optimum thermal properties.

02

Simultaneous machining with up to 4 cross slides in a single clamping operation drastically reduces set-up and cycle times with the highest shape and position tolerances.

03

Individual automation concepts offer simple, pragmatic through to highly complex solutions.

04

The large 22" ergonomic operation panel not only has excellent haptic properties. It can also be operated intuitively and configured individually without additional displays.

05

The Buderus multifunctional head and the NS axis, which can be swiveled continuously up to 225°, allow the individual and flexible integration of different technologies.

The machines enable both combined and simultaneous machining processes. The flexible configuration options allow a wide range of machining technologies from grinding, hard turning and honing to the use of driven tools. This means that the 235VH can also achieve the shortest possible routing and machining times.

Buderus is also the specialist in the use of center drive technology. Our latest development is the center drive machine 235VM with an advanced drive head. This new head achieves a working speed of up to 2,500 rpm and therefore also enables the hard turning of components. The innovative machine platform of the 235 VM is specially designed for machining rotationally symmetrical workpieces with a workpiece diameter of up to 80 mm and a length of up to 450 mm. The 235 VM enables both combined and simultaneous machining processes using a center drive.

The major advantage of center drive technology is the ability to machine internal and external geometries in just one clamping operation, which has a positive effect on both the precision of the machining process and significantly increases its efficiency.

Highlights:

01

The unique sustainable machine bed made of natural granite ensures high process stability thanks to maximum rigidity, vibration damping and optimum thermal properties.

02

Simultaneous machining with up to 4 cross slides in a single clamping operation drastically reduces set-up and cycle times with the highest shape and position tolerances.

03

Individual automation concepts offer simple, pragmatic through to highly complex solutions.

04

The large 22" ergonomic operation panel not only has excellent haptic properties. It can also be operated intuitively and configured individually without additional displays.

05

The Buderus multifunctional head and the NS axis, which can be swiveled continuously up to 225°, allow the individual and flexible integration of different technologies.