Industry 4.0

The Intelligent Alarm

The deployment of alarm management solutions is very common in manufacturing plants nowadays. To monitor breakdowns and to close safety gaps at machines, companies need software that provides valuable information and helps to identify important coherences in data. With Smart Alarm, SMS digital GmbH developed an intelligent alarm and maintenance management system that supports plant operators and maintenance managers in their daily work.

In the future, it will be essential for plant operators to detect the coherences in the alarm data and to document them fastly. In order to reach these goals, it is necessary to implement a transparent and reliable alarm management system that is customizable to individual industrial needs.

Plant availability and productivity are increased by making fast and reliable decisions. In addition, the communication between operators and maintenance is improved: On the one hand, operators do not have to inform maintenance in case of incidents since it is done automatically and can focus on trouble shooting. On the other hand, maintenance can easily access alarms themselves and is not relying on being properly informed by operators.

Also in the fields of controlling and management, the maintenance functionality is very interesting as production costs and downtimes can be reduced significantly. Formerly developed in order to solve a particular customer issue, Smart Alarm is now one of the core products at SMS digital.

The intelligent alarm allows the user to notice relevant messages more quickly. Image courtesy of SMS digital

The increasing number of alarms in automation projects leads to several challenges: Important alarms are being overlooked and root cause analyses done by managers become time consuming. To improve these circumstances, the Engineering Equipment & Materials Users Association (EEMUA 191) provides a guideline for effective alarm management. It proposes a maximum of six alarms per hour.

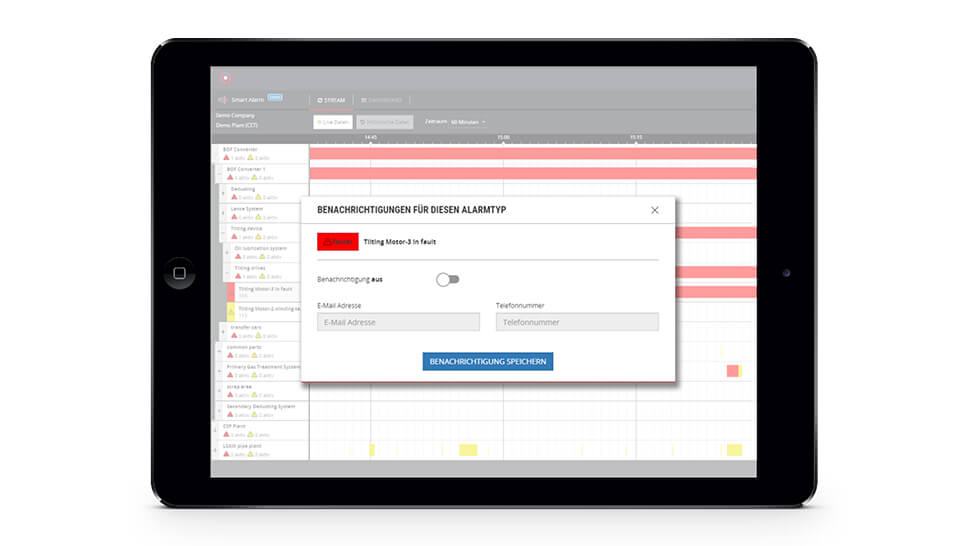

Since this is quite unrealistic for production systems, users are seeking for systems to increase transparency and reduce the vast amount of alarms. Smart Alarm provides a better supervision of the countless alarms that are triggered in plants every day. With an intelligent prioritization, a direct link-up with proposals for solutions, automated notifications and intelligent analyses, Smart Alarm puts a stop to lengthy fault analyses. Moreover, Smart Alarm makes expert knowledge available to all employees and can be connected to any plant, regardless of the supplier or automation system.

The implementation is quick and easy: In less than 48 hours, Smart Alarm can usually be installed via a remote connection at the customer’s site. SMS digital also provides the required server infrastructure and uses Smart Alarm as a Software as a Service (SaaS) solution. This means, Smart Alarm is centrally hosted by SMS digital, whereby software updates and further software developments are available for the customer automatically.

The time required to detect and solve problems in a system is significantly reduced by the smart alarm. Machine learning and artificial intelligence help. Image courtesy of SMS digital

Visualization: In the event of a fault in the system, the cause of the alarm is displayed. Errors that are not stored can be quickly added to.

Plant operators can better use and evaluate the alarm data of the plant units. Nowadays, it is common that even single lines are automated with up to five different automation systems. This issue leads to a quite complex evaluation and troubleshooting process.

One key advantage is that plants can extract data from a wide variety of systems and aggregate and evaluate it using a central software. The visualization option in the dashboard provides a sorted overview of all processes as well as necessary maintenance work and can be accessed from any mobile device in real time.

Several customers around the world are already using Smart Alarm. User specific views on the alarms enables a wide range of people to benefit from information in alarms – from maintenance managers over electrical, hydraulic and even mechanical maintenance personnel up to automation-responsible persons.

Example: Preventing unplanned downtimes

The operator neglects to inform the maintenance manager about an oil level warning, so the maintenance manager overlooks the problem and does not refill the oil. As a result, the machine stops at low-low alarm and this leads to production losses and unplanned stoppages. How to solve this problem? The solution is Smart Alarm: The maintenance manager will automatically be informed by Smart Alarm about a low oil level and can refill oil until the next planned stoppage, where the leakage can be fixed without causing extra downtime and costs.

Example: Reducing Maintenance Costs

A machine is realigned every 6 months for preventive or planned maintenance reasons. With Smart Alarm it could be seen that corresponding alarms of malalignment were not reduced significantly after maintenance action. As a first step, the interval is prolonged to 9 months, saving 1/3 of the maintenance costs. In the future, alarms might be used to determine the best time for the maintenance, reducing costs again.

Example: Acting Faster

The maintenance manager cleans up his alarm screen using Smart Alarm, focusing only on for him important messages. For very critical ones, he even activates notifications to his mobile phone. He has an extra screen with the for him relevant alarms, allowing him to be informed about relevant events and being able to go and fix the machine in case of a problem proactively.

Contact

Dr. Jesper Mellenthin

Head of Sales

SMS digital GmbH

Düsseldorf

Germany

Phone: +49 211 881 4956

Send e-mail