Fastems Exhibit at Gear Expo Highlights Automation Systems & Software

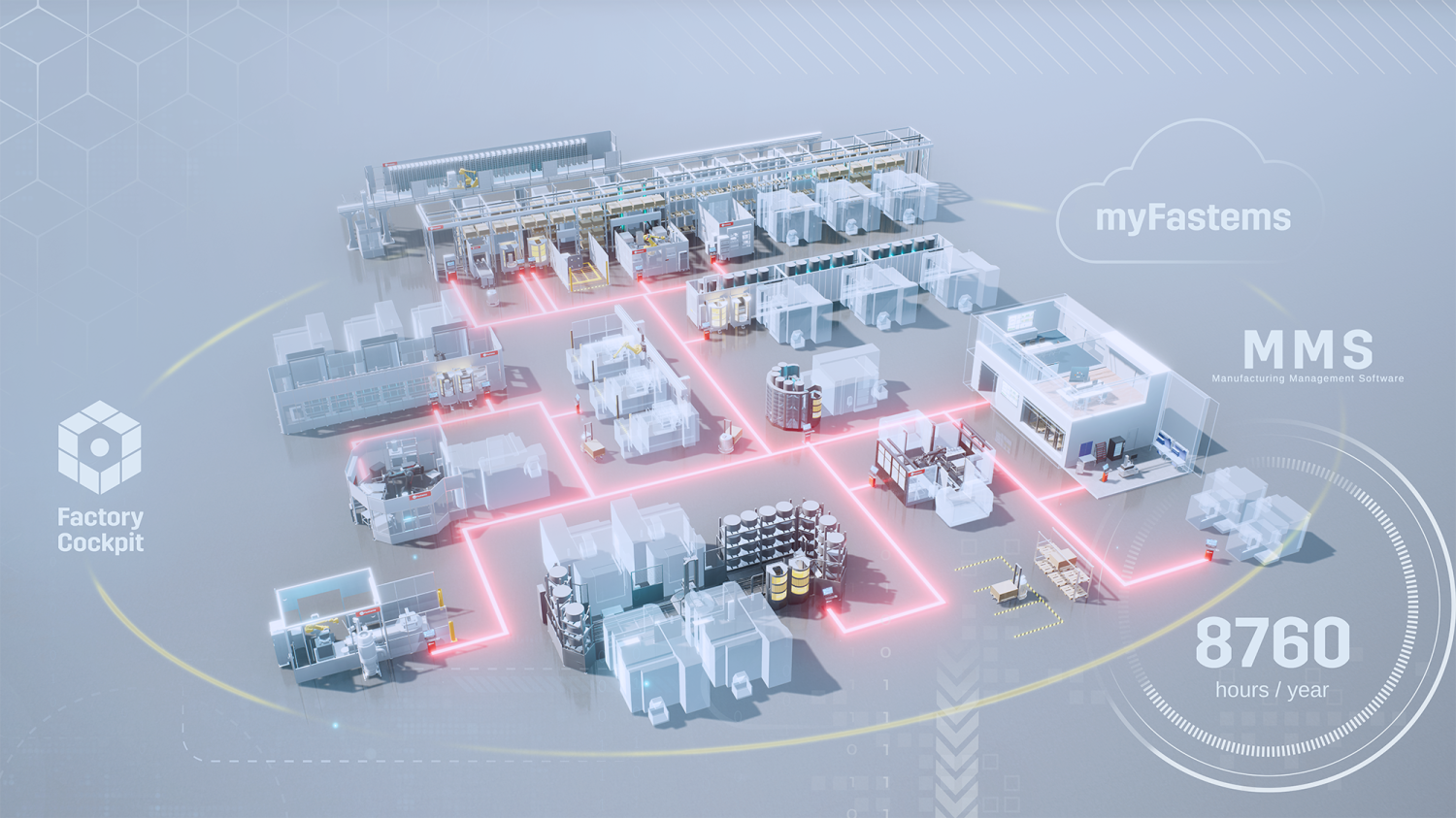

Fastems, a leading provider of factory automation systems, will introduce the latest release of its software for automated pallet handling for the metalworking industry during Gear Expo in booth 307. The company will also share information about its Flexible Manufacturing Systems, robotics, and other automation solutions, specifically as they relate to gear manufacturing.

Fastems’ Manufacturing Management Software (MMS) is one of the most progressive solutions for automatic production processing, complete with planning, controlling, visualization and monitoring capabilities. Based on a manufacturer’s current order and all required or available resources, the software plans the production straight from an ERP system. Not only does MMS administrate all NC programs needed for the production processes, but also all the tool data. It also monitors tool life and prompts the operator for new tooling if required. If an unforeseen situation should arise that was not included in the production plan — for example a particularly urgent order, MMS will, if prompted, automatically rearrange the schedule in real time, taking into account the changed production process priorities.

The new MMS Version 6 offers critical benefits to users – both on the shop floor and at the management level. The user interface is now based on HTML 5 technologies. As HTML 5 supports various hardware platforms and operating systems, the new interface creates the key prerequisites for the smooth transformation production processes as defined by Industry 4.0. As a browser-based solution, it makes it possible to access current production information from anywhere in the world via secure Internet connections. Given this scenario, the use of smart phones and tablet PCs also enables users to plan and access the system no matter where they are located. Moreover, the solution makes it possible to monitor live production data on any electronic device with Internet access.

The updates to Version 6 were based on a series of suggestions and feedback from customers in conjunction with Fastems’ engineers. Some of the customer-driven improvements include utilities for advance production order planning long before they are in queue for machining. Another new feature is the simulation of the anticipated capacity usage level in an automatic production process, along with the related order-dependent production schedule. Hence, MMS Version 6 does not only provides more concise insights into the ongoing production processes, but also enables users to plan future manufacturing runs much more precisely. To make this possible, MMS Version 6 contains an entirely new set of software tools that allow users to verify the future production resource requirements. For example the availability of materials, tools, and the upcoming capacity requirements of the machines, can all be assessed before the execution of pending orders is initiated. To further complement the solution, the expanded MMS planning tool provides the user with an optimized overview of the current production process, its progression through the system, and the completion of orders by the deadline date.

In addition to software, Fastems is perhaps better known in manufacturing for its pallet and workpiece handling systems which span the range from single machine tool pallet transfer components to full-factory automation systems. Included in their expertise are Multi-Level Systems, Flexible Pallet Container Systems, Flexible Manufacturing Systems and several robotic options for workpiece handling.

For more information, visit Gear Expo 2017, booth 307, visit www.fastems.com, or call toll-free 866-702-0611.