Taps and thread milling cutters for threading aluminium and aluminium alloy parts.

Nowadays, we are immersed in demanding energy saving and sustainability policies; for this reason, the whole industry is increasingly required to reduce the weight of components in order to reduce energy consumption, whether electric, gas or conventional fuels, and the use of modern injection and molding techniques allows the industry to create geometrically complex parts capable of correctly supporting the required mechanical demands. But the increased use of aluminium and magnesium alloys in the industry has required the evolution of tools and coatings, with specific solutions for these applications.

Significant examples can be found in the industry of parts and components for the aeronautical, automotive, railroad, etc. sectors, where weight reduction is linked to the achievement of light, safe and resistant parts and structures that reduce overall energy consumption. In other sectors, the reason is perhaps not so much weight reduction as the geometrical complexity that allows the use of die castings of aluminium and magnesium alloys.

The use of modern injection and molding techniques allows the industry to create geometrically complex parts capable of correctly supporting the required mechanical demands. But the increased use of aluminium and magnesium alloys in the industry has required the evolution of tools and coatings, with specific solutions for these applications.

These days, we no longer speak of aluminium in generic terms, but rather we specify its silicon content, whether it is injected or extruded, so that once the type of alloy has been determined, we can offer the most optimal, efficient and sustainable threading solution.

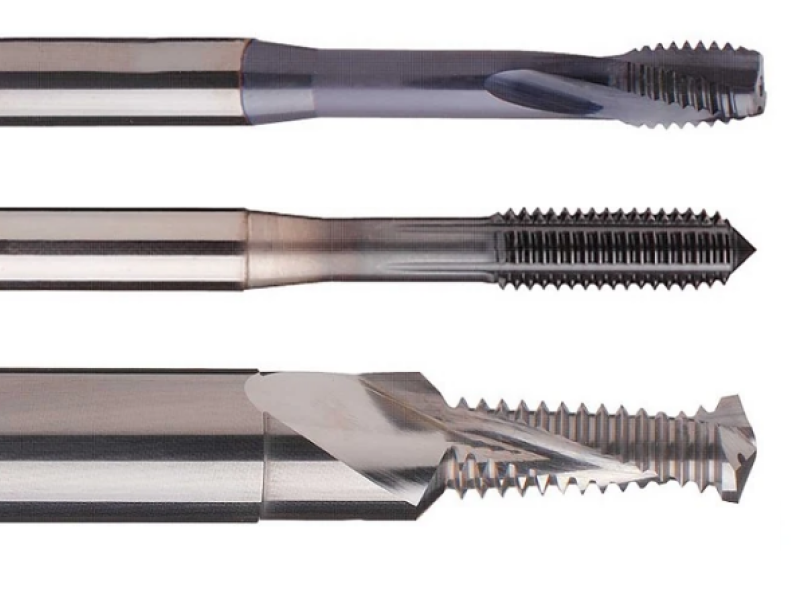

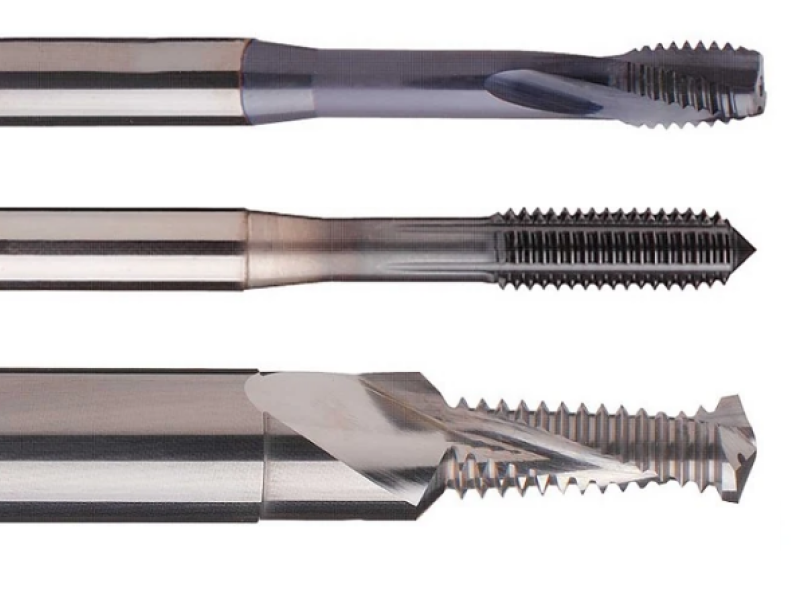

FERG offers its customers high quality threading tools with a geometry specially designed for these alloys: taps or thread milling cutters, manufactured with the best conventional high-speed steels, powder metallurgy steels, in micrograin carbide or mixed HSS/HM materials:

Rolling taps: C171A, AC171A, DL171A, C175A, AC175A, DL175A, DL175A taps with different coatings and geometry adapted to the tapping of different aluminium and magnesium.

Cutting taps C130A, AC130A, DL130A: taps for through holes in magnesium alloys and aluminium alloys with <10% Si.

Cutting taps AC134A, DL134A: taps for through holes in aluminium alloys with Si 6 -:- 10%.

Cutting taps C140A, AC140A, DL140A: taps for blind holes in magnesium and aluminium alloys with Si <10%.

Cutting taps AC144A, DL144A: taps for blind holes in aluminium alloys with Si 6 -:- 10%.

Cutting taps AC142A, DL142A: taps for blind holes in aluminium castings with Si >10%.

Cutting taps A740A, DL740A: Micrograin solid carbide taps for blind holes in aluminium castings of Si >10%.

BGF micrograin integral carbide thread milling cutters: tool that drills, chamfers and threads by interpolation.

GSF micrograin carbide thread milling cutters: tool that allows the threading of threads of different sizes.

Micrograin carbide thread milling cutters GSFM: tool that chamfers and threads by interpolation.

Micrograin carbide thread milling cutters GF: tool that allows the threading of threads of different sizes.

Aluminum threading taps with inserts: EG M, EG MF.

The range that FERG has as standard design covers most of the threading needs, but we also make special applications, adaptations or executions that allow us to adapt our tools to the requirements and needs of our customers.

Nowadays, we are immersed in demanding energy saving and sustainability policies; for this reason, the whole industry is increasingly required to reduce the weight of components in order to reduce energy consumption, whether electric, gas or conventional fuels, and the use of modern injection and molding techniques allows the industry to create geometrically complex parts capable of correctly supporting the required mechanical demands. But the increased use of aluminium and magnesium alloys in the industry has required the evolution of tools and coatings, with specific solutions for these applications.

Significant examples can be found in the industry of parts and components for the aeronautical, automotive, railroad, etc. sectors, where weight reduction is linked to the achievement of light, safe and resistant parts and structures that reduce overall energy consumption. In other sectors, the reason is perhaps not so much weight reduction as the geometrical complexity that allows the use of die castings of aluminium and magnesium alloys.

The use of modern injection and molding techniques allows the industry to create geometrically complex parts capable of correctly supporting the required mechanical demands. But the increased use of aluminium and magnesium alloys in the industry has required the evolution of tools and coatings, with specific solutions for these applications.

These days, we no longer speak of aluminium in generic terms, but rather we specify its silicon content, whether it is injected or extruded, so that once the type of alloy has been determined, we can offer the most optimal, efficient and sustainable threading solution.

FERG offers its customers high quality threading tools with a geometry specially designed for these alloys: taps or thread milling cutters, manufactured with the best conventional high-speed steels, powder metallurgy steels, in micrograin carbide or mixed HSS/HM materials:

Rolling taps: C171A, AC171A, DL171A, C175A, AC175A, DL175A, DL175A taps with different coatings and geometry adapted to the tapping of different aluminium and magnesium.

Cutting taps C130A, AC130A, DL130A: taps for through holes in magnesium alloys and aluminium alloys with <10% Si.

Cutting taps AC134A, DL134A: taps for through holes in aluminium alloys with Si 6 -:- 10%.

Cutting taps C140A, AC140A, DL140A: taps for blind holes in magnesium and aluminium alloys with Si <10%.

Cutting taps AC144A, DL144A: taps for blind holes in aluminium alloys with Si 6 -:- 10%.

Cutting taps AC142A, DL142A: taps for blind holes in aluminium castings with Si >10%.

Cutting taps A740A, DL740A: Micrograin solid carbide taps for blind holes in aluminium castings of Si >10%.

BGF micrograin integral carbide thread milling cutters: tool that drills, chamfers and threads by interpolation.

GSF micrograin carbide thread milling cutters: tool that allows the threading of threads of different sizes.

Micrograin carbide thread milling cutters GSFM: tool that chamfers and threads by interpolation.

Micrograin carbide thread milling cutters GF: tool that allows the threading of threads of different sizes.

Aluminum threading taps with inserts: EG M, EG MF.

The range that FERG has as standard design covers most of the threading needs, but we also make special applications, adaptations or executions that allow us to adapt our tools to the requirements and needs of our customers.