Fill Time Machine – look into the future of machining technology

Fill Media Service September 2023

Industry/Machine Engineering/Metalworking/Innovation/Trade Fair

Fill Time Machine – look into the future of machining technology

The Austrian company shows how high-tech mechanical engineering and digital tools can be combined to maximum effect.

Fill develops tailor-made solutions along the entire value creation chain, from automation to the machined, finished, tested, and packaged workpiece. The latest innovations will be presented under the banner of "The Fill Time Machine" at the world's leading trade fair for production technology, EMO 2023, in Hannover from September 18 to 23, 2023 on Fill's exhibition stand in Hall 012/C12.

Gurten/Hannover, September 18, 2023 – "For us, innovation means being one step ahead at all times. Our engineers' passionate commitment to development leads to new solutions, while production and machining systems continuously enhanced and optimized. This generates a decisive competitive advantage for our customers. They can launch their products not only more quickly, but also more efficiently," explains Friedrich Dallinger, Head of the Metal Machining Technology Competence Center at Fill. Dallinger and his team are looking forward to many interesting discussions on the Fill exhibition stand.

SYNCROMILL C22-63/1000 – perfect machining of large structural parts and framework components

With a 1,000 mm spindle spacing and an integrated pallet changer, the SYNCROMILL C22-63/1000 machining center has been developed above all for the efficient machining of large structural parts, framework components, and battery housings. Simultaneous loading and machining and the innovative tool-change concept enable extremely short non-productive times and, consequently, high production quantities. The pallet change facility also offers the opportunity to produce different workpieces and machining scopes extremely economically without retooling the machine. The interlinking with upstream or downstream processes can be adapted flexibly to meet individual customer requirements.

SYNCROMILL C21-63/1500 – compact, dynamic, flexible

Exceptionally compact dimensions of 4.9 x 4.8 meters, an extremely large operating range of 1,500 x 1,200 millimeters, and short chip-to-chip times of 2.0 seconds are just some of the success criteria of the newly developed SYNCROMILL C21-63/1500. The focus here is on aluminum structural components and extruded profiles. The flexible machine concept enables efficient implementation of the widest variety of machining tasks in highest quality.

SYNCROMILL D22-63/X2000 – for large-volume workpieces

Whether axle beams, battery trays, Mega-Casting and Giga-Casting or other large-volume workpieces, the D22-63/X2000 machining center with its intelligent clamping concept and space-saving machining, represents the best solution. Due to the variable positioning of the rotary table, a very economical machining can be achieved.

As well as short chip-to-chip times, the laterally positioned tool magazine also facilitates excellent accessibility. The SYNCROMILL D is available as single machine SYNCROMILL D11 or double machine D22.

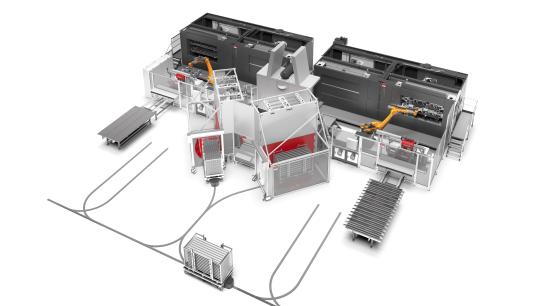

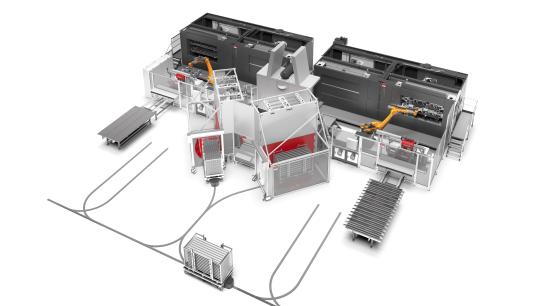

Flexible Profile Machining System

Continuous changes in markets and components make the machining and automation of profiles for structural framework components and battery housings a

major challenge. Fill offers highly efficient SYNCROMILL machine tools for the process, with ideal clamping and tooling concepts and specifically tailored automation components. For optimum yield, we define the use of highly flexible, driverless transport systems (FTS) as well as robot or portal solutions. Retooling for the implementation of future components is already taken into account in the system concept.

ROBOT TRIMMING CELL – precision redefined

Fill has developed the ACCUBOT NC robot for applications with the most demanding accuracy requirements. Apart from the machining of outlines and tooling of the customizable clamping fixture, the tasks of the ROBOT TRIMMING CELL include the geometrical measurement of structural components made of lightweight materials. In these processes, different functional units are coupled and decoupled fully automatically on the robot. The intelligent, easily operated FILL STUDIO software solution allows different processes on a production cell to be represented.

FILL CYBERNETICS – digital analyses in real time

The CYBERNETICS products are a key component of Fill’s machines and systems. They cover the entire bandwidth of required solutions – from the monitoring of complex individual operations and seamless component traceability, through to automated system optimization by means of artificial intelligence (AI). Not only standard solutions, but also customer-specific and platform-independent dashboards, provide an optimum overview and enable detailed analyses of production and machines. This enables consistently high availability levels and boosts productivity. The CYBERNETICS ANALYZE analysis platform is used to record and store all the relevant machine parameters of a SYNCROMILL system. With the help of edge computing and modern software architecture, the required evaluations and analyses can be activated and deactivated again at any time. CYBERNETICS VISION is the umbrella term for all industrial image processing solutions. Fill's experts develop optical test systems and check them for cost efficiency and against technical requirements. Fill offers a wide range of applications for various materials and surfaces – from simple 2D position recognition and type checks, to 3D component reconstructions, through to optical quality control of surfaces by means of self-learning algorithms that imitate the decisions of the system operator.

Fill Service Platform – 24 hours a day

The Fill Service Platform is a highly professional tool for supporting the continuous workflow and ensuring high productivity. The digital service is offered around the clock. All the relevant information for all Fill systems, (service cases, documents, contacts, system documentation, and much more) can be called up via the platform. Service notifications can be viewed in real time and the whole service history is available.

Corporate data

Fill is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports, and building industries all benefit from Fill’s expertise. Since it was founded in 1966, the company has distinguished itself through enormous innovative strength, strong values and the best jobs. “If you are seeking the best solution, shape your future with Fill” is the guiding principle of the company’s more than 1,000 employees. “Wir sind 1! We are one!” is their vision and stands for togetherness not only with the team, but also with customers, suppliers and partners. The company is 100 percent family-owned and managed by Andreas Fill (CEO), Martin Reiter (CFO), Alois Wiesinger (CTO), and Günter Redhammer (COO). In 2022, Fill recorded sales of around 187 million euros.

Further information can be found at: www.fill.co.at

If you have any questions, please contact:

Kommhaus

Altausseer Strasse 220

8990 Bad Aussee, Austria

Tel.: +43 3622 55344-0

E-mail: [email protected]

Fill Media Service September 2023

Industry/Machine Engineering/Metalworking/Innovation/Trade Fair

Fill Time Machine – look into the future of machining technology

The Austrian company shows how high-tech mechanical engineering and digital tools can be combined to maximum effect.

Fill develops tailor-made solutions along the entire value creation chain, from automation to the machined, finished, tested, and packaged workpiece. The latest innovations will be presented under the banner of "The Fill Time Machine" at the world's leading trade fair for production technology, EMO 2023, in Hannover from September 18 to 23, 2023 on Fill's exhibition stand in Hall 012/C12.

Gurten/Hannover, September 18, 2023 – "For us, innovation means being one step ahead at all times. Our engineers' passionate commitment to development leads to new solutions, while production and machining systems continuously enhanced and optimized. This generates a decisive competitive advantage for our customers. They can launch their products not only more quickly, but also more efficiently," explains Friedrich Dallinger, Head of the Metal Machining Technology Competence Center at Fill. Dallinger and his team are looking forward to many interesting discussions on the Fill exhibition stand.

SYNCROMILL C22-63/1000 – perfect machining of large structural parts and framework components

With a 1,000 mm spindle spacing and an integrated pallet changer, the SYNCROMILL C22-63/1000 machining center has been developed above all for the efficient machining of large structural parts, framework components, and battery housings. Simultaneous loading and machining and the innovative tool-change concept enable extremely short non-productive times and, consequently, high production quantities. The pallet change facility also offers the opportunity to produce different workpieces and machining scopes extremely economically without retooling the machine. The interlinking with upstream or downstream processes can be adapted flexibly to meet individual customer requirements.

SYNCROMILL C21-63/1500 – compact, dynamic, flexible

Exceptionally compact dimensions of 4.9 x 4.8 meters, an extremely large operating range of 1,500 x 1,200 millimeters, and short chip-to-chip times of 2.0 seconds are just some of the success criteria of the newly developed SYNCROMILL C21-63/1500. The focus here is on aluminum structural components and extruded profiles. The flexible machine concept enables efficient implementation of the widest variety of machining tasks in highest quality.

SYNCROMILL D22-63/X2000 – for large-volume workpieces

Whether axle beams, battery trays, Mega-Casting and Giga-Casting or other large-volume workpieces, the D22-63/X2000 machining center with its intelligent clamping concept and space-saving machining, represents the best solution. Due to the variable positioning of the rotary table, a very economical machining can be achieved.

As well as short chip-to-chip times, the laterally positioned tool magazine also facilitates excellent accessibility. The SYNCROMILL D is available as single machine SYNCROMILL D11 or double machine D22.

Flexible Profile Machining System

Continuous changes in markets and components make the machining and automation of profiles for structural framework components and battery housings a

major challenge. Fill offers highly efficient SYNCROMILL machine tools for the process, with ideal clamping and tooling concepts and specifically tailored automation components. For optimum yield, we define the use of highly flexible, driverless transport systems (FTS) as well as robot or portal solutions. Retooling for the implementation of future components is already taken into account in the system concept.

ROBOT TRIMMING CELL – precision redefined

Fill has developed the ACCUBOT NC robot for applications with the most demanding accuracy requirements. Apart from the machining of outlines and tooling of the customizable clamping fixture, the tasks of the ROBOT TRIMMING CELL include the geometrical measurement of structural components made of lightweight materials. In these processes, different functional units are coupled and decoupled fully automatically on the robot. The intelligent, easily operated FILL STUDIO software solution allows different processes on a production cell to be represented.

FILL CYBERNETICS – digital analyses in real time

The CYBERNETICS products are a key component of Fill’s machines and systems. They cover the entire bandwidth of required solutions – from the monitoring of complex individual operations and seamless component traceability, through to automated system optimization by means of artificial intelligence (AI). Not only standard solutions, but also customer-specific and platform-independent dashboards, provide an optimum overview and enable detailed analyses of production and machines. This enables consistently high availability levels and boosts productivity. The CYBERNETICS ANALYZE analysis platform is used to record and store all the relevant machine parameters of a SYNCROMILL system. With the help of edge computing and modern software architecture, the required evaluations and analyses can be activated and deactivated again at any time. CYBERNETICS VISION is the umbrella term for all industrial image processing solutions. Fill's experts develop optical test systems and check them for cost efficiency and against technical requirements. Fill offers a wide range of applications for various materials and surfaces – from simple 2D position recognition and type checks, to 3D component reconstructions, through to optical quality control of surfaces by means of self-learning algorithms that imitate the decisions of the system operator.

Fill Service Platform – 24 hours a day

The Fill Service Platform is a highly professional tool for supporting the continuous workflow and ensuring high productivity. The digital service is offered around the clock. All the relevant information for all Fill systems, (service cases, documents, contacts, system documentation, and much more) can be called up via the platform. Service notifications can be viewed in real time and the whole service history is available.

Corporate data

Fill is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports, and building industries all benefit from Fill’s expertise. Since it was founded in 1966, the company has distinguished itself through enormous innovative strength, strong values and the best jobs. “If you are seeking the best solution, shape your future with Fill” is the guiding principle of the company’s more than 1,000 employees. “Wir sind 1! We are one!” is their vision and stands for togetherness not only with the team, but also with customers, suppliers and partners. The company is 100 percent family-owned and managed by Andreas Fill (CEO), Martin Reiter (CFO), Alois Wiesinger (CTO), and Günter Redhammer (COO). In 2022, Fill recorded sales of around 187 million euros.

Further information can be found at: www.fill.co.at

If you have any questions, please contact:

Kommhaus

Altausseer Strasse 220

8990 Bad Aussee, Austria

Tel.: +43 3622 55344-0

E-mail: [email protected]