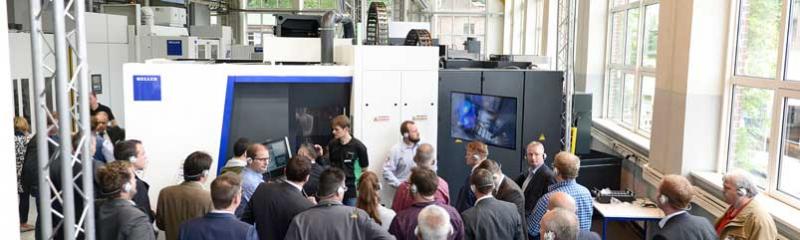

With the 9th edition of Werktage in Nürtingen HELLER demonstrated its commitment to offering users maximum benefit with more than productive machining centres. With increasing visitor numbers compared to previous years, the interest in the specialist topics presented was enormous: from the presentation of the new HF series, to the added-value of HELLER4Industry in the context of Industry 4.0, through to panel discussions with a strong emphasis on practical relevance.

The new concept of the HELLER HF series incorporates a 5th axis provided by the workpiece for dynamic 5-sided (3 + 2) and simultaneous 5-axis machining. To achieve this, proven components from existing series were recombined to develop a 5-axis machining centre for a wide range of parts and materials, particularly suited to the needs of the automotive industry and its suppliers and the general machine industry.

Proven components include the inherently rigid bed and column design, kinematics with three linear axes in X, Y and Z and two direct driven dynamic rotary axes in A and B, with the A axis supported by a counter bearing. All this helps to achieve the necessary stiffness even under high loads. Optionally, the powerful dynamics can be increased further with the “Speed-Dynamics Package”. According to HELLER, it provides 10% shorter chip-to-chip times.

Practice-oriented exchange of experiences

The panel discussions were mainly characterised by positive experiences and extremely complex manufacturing tasks.

Klinger Fluid Control based in Gumpoldskirchen/Austria relocated core competencies from China back to Austria and is competing successfully with Chinese and other European suppliers, operating two new HELLER 4-axis machining centres model H 6000.

To Bitzer Kühlmaschinenbau GmbH from Rottenburg/Germany, the service quality was one of the reasons to opt for HELLER. The company also purchased two HELLER 4-axis machining centres model H 6000.

The reason why WESO Aurorahütte based in Gladenbach/Germany buys HELLER machines is the confidence in the manufacturer built over many years. For the milling and turning of safety-relevant, complex components, the company invested in a 5-axis machining centre model CP 6000. Meanwhile the performance targets the company had set itself have been achieved successfully.

Industry 4.0 made by HELLER

Today, the term Industry 4.0 is mostly associated with catchwords such as digitisation, network integration or transparency. By now, HELLER has further developed industrial production with digitisation and network integration of information and production technologies. Whilst achieving this, efficient and productive manufacturing and the reduction of workpiece costs are in the foreground. In terms of Industry 4.0, HELLER's approach is to enhance transparency of the current machine status, evaluating the information gained in combination with existing data to allow purposeful diagnostics. To achieve this, future machine functions will be combined with powerful data extraction amongst other measures.

During HELLER WerkTage 2016, HELLER will be presenting three examples demonstrating the importance of ease of operation, customised manufacturing of a workpiece and enhanced evaluation of existing sensor data. HELLER4Operation refers to an easy-to-use, operator-oriented user interface. The use of touch controls at the tool/workpiece loading station enables fast operation.

The HELLER4Services module combines digital services. The HELLER Services Interface presented focuses on transparency of manufacturing and maintenance processes. The HELLER4Performance module provides machine analysis for process and performance optimisation as well as time-synchronous extraction of real-time data into the internet.

Added value for the future

Strong attendance with visitors from 22 nations speaks for itself. At the same time it is the result of the consistent development of the sales and service strategy and the systematic development of selected target markets, providing interesting market potential. HELLER also believes that its current products and services provide further opportunities. The new HF series of 5-axis machines, for example, helps to attract new customers and industries and to open new fields of application. With focused technologies and novelties HELLER again succeeded in convincing visitors with manufacturing solutions, offering added value now and in the future.

Germany

Germany