Hofmann Mess- und Auswuchttechnik GmbH & Co. KG

Products

Analytical devices

Balancing instruments and equipment

Electronic Grinding Wheel Balancing Device

|

Balancing instrument and equipment

Hofmann Mess- und Auswuchttechnik GmbH & Co. KG

Balancing instruments and equipment

900-2580

Hofmann's vibration measuring and balancing device EasyBalancer EB 3500 is specially designed for balancing grinding wheels and grinding spindles. The spread angle method integrated in the EB 3500 for balancing in one plane is controlled by a clearly structured operator dialog. Unbalance correction using the sliding weight positions are determined automatically. In addition, the EB 3500 offers measurement of the speed-synchronous unbalance vibration and the overall vibration in the range from 10 Hz to 1 kHz. The overall vibration is the basis for assessing the machine and auxiliary equipment condition in accordance with DIN ISO 20816-1. The optional function rolling bearing condition is determined according to the shock pulse method. The measurement results may be saved in the file manager and recalled directly into the device at any time. Transfer to a PC is possible via USB interface. The EB 3500 package includes a PC program that may be used to easily create customer-specific measurement reports.

Advantages

- Specially designed for field application

- Portable, quickly deployed

- USB interface

- Measurement data storage function

- Measurement log for PC

- Simple operator guidance with high-resolution touchscreen

- Low cost; high performance

Applications

- Grinding wheel and spindle field balancing

- Detect vibrations at bearings and machine housings

- Machine and auxiliary equipment condition assessment

- Vibration Measurement

- Unbalance measurement

- RPM measurement

- Roller bearing condition measurement

Other devices for specific testing and analytical procedures

Spin bench type eSpin by deineMaschine

|

Other device for specific testing and analytical procedure

Hofmann Mess- und Auswuchttechnik GmbH & Co. KG

Other devices for specific testing and analytical procedures

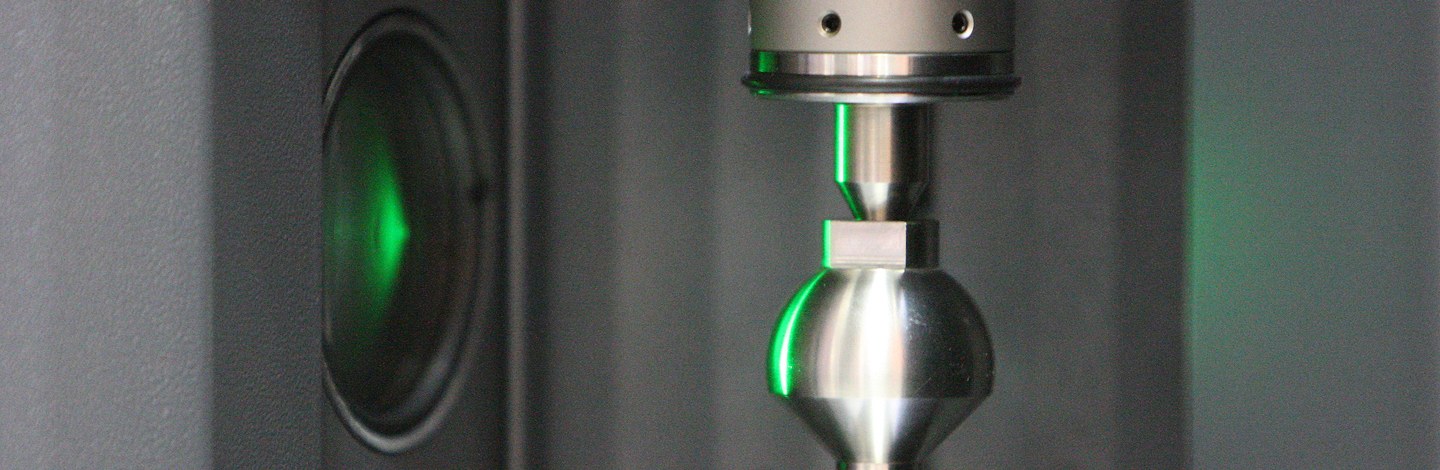

Spin benches are indispensable for the development, prototype testing, quality assurance and production of rotors to be investigated by their rotation in the centrifugal field.

Mechanical structure of a centrifugal stand of the eSpin series:

Our revolutionary direct electric drive is at the heart of the machine. Thanks to the innovative modular system, we can achieve the finest gradations depending on the required speed and rotor weight. Here, we rely on variable axial bearings and different motors that are used depending on the load requirement profile. Thanks to the direct drive concept, we completely dispense with toothed components and minimize the number of rotating parts. This keeps our machine reliable and low-maintenance. In the event of a burst, the drive is protected by a standardized shaft support. Regular maintenance of the direct drives can be carried out quickly and cost-effectively.

The most obvious feature of our eSpin is the vacuum-tight centrifugal bowl with integrated burst protection. Our special safety concept prevents fragments from escaping from the container in the event of a burst by means of an almost circumferential lid lock and a constructive labyrinth seal. This also provides adequate protection against dust explosions and the resulting internal pressure. Multi-layer protection rings absorb the kinetic energy of the fragments of a ruptured rotor and break them down.

Up to a size of eSpin 1000 (max. 1,000mm rotor diameter), the machine is installed directly on the hall floor and, thanks to its optimized design with a height of less than 4 meters, fits through standard hall doors. This simplifies the insertion as part of the installation and reduces the requirements for the installation site in terms of hall height and the usability of overhead cranes.

Special features:

- Standardized shaft mounting, almost circumferential cover locking, constructive labyrinth seal and vacuum-tight centrifugal container for optimum protection in the event of bursting

- Optimized design means that up to the size of the eSpin 1000, the machine is installed directly on the shop floor for simplified installation and reduced site requirements

- central, computer-supported control and measurement data acquisition system is optional add-ons

- includes numerous monitoring systems for safety

- low noise level with less than 75 dB (A)

- market leader in energy efficiency

- further options available (e.g. heating and cooling of the rotor, measurement technology for expansion measurement or condition monitoring during endurance tests, telemetry system, high-speed camera)

Range of application:

- Burst tests (To determine rotor limits and confirm models).

- Strength tests (For quality assurance, into the specified overspeed ranges)

- Material hardening (by accelerating into the flow range of the material)

- HFC test

- LCF test

Field Balancing Instrument and Vibration Meter

|

Other device for specific testing and analytical procedure

Hofmann Mess- und Auswuchttechnik GmbH & Co. KG

Other devices for specific testing and analytical procedures

Vibrations on machines or rotors may cause damage and lead to manufacturing errors. In no time, the compact and easy to operate Minibalancer MI 2500 helps you to identify vibrations, resonances and correct the unbalance. A must have for service, maintenance and development! The Minibalancer MI 2500 is a two-plane vibration measuring and field balancing device. Its operation is self-explanatory through a high-resolution touchscreen. The unbalance correction is carried out using a polar graph, component or the spread angle method. The overall vibration measurement is carried out in accordance with DIN ISO 20816-1 and is used to assess the machine condition. The condition of the rolling bearings may be measured using the shock pulse method. The vibration analysis helps to identify resonances that simplifies the balancing process. The measurement results may be saved in the file manager and recalled directly into the device. Transfer to a PC is possible via USB interface. The scope of delivery includes a PC program that may be used to easily create customer-specific measurement reports.

Special features:

- Simple user guidance with high-resolution touchscreen

- Portable, quickly deployable

- USB interface

- Measurement data storage function

- Measurement log for PC

- Very good price/performance ratio

Applications:

- Field balancing in single- or two-plane

- Detect vibrations at bearings and machine housings

- Machine and auxiliary equipment condition assessment

- Vibration Measurement

- Imbalance measurement

- rpm measurement

- Bearing condition measurement

- Vibration analysis