HWACHEON Machine Tools

Products

Machining centres

Five-axis milling machining centres

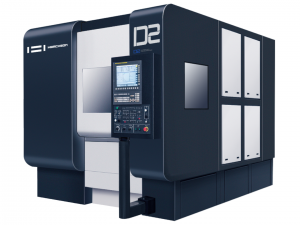

D2-5AX

|

5 Axis Machining Center

HWACHEON

Five-axis milling machining centres

| Workspace |

|

| 675 mm | |

| 500 mm | |

| 499 kg | |

| Travel |

|

| 650 mm | |

| 500 mm | |

| 500 mm | |

| Machine control |

|

| Fanuc | |

The compact D2-5AX is designed for use in workshops, education, laboratories and for tool, jig, die and mould making. The D2-5AX has 5 axes as standard, of which 4 can be controlled simultaneously.

Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power of the D2-5AX derive from its heavy machine bed of 10 tonnes, spindles made by Hwacheon and the use of high quality components. Thanks to its ergonomic construction, high rapid traverse speed, and its ease of automation, the D2-5AX is ideal for high productivity applications, whether for small or large numbers of units.

Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power of the D2-5AX derive from its heavy machine bed of 10 tonnes, spindles made by Hwacheon and the use of high quality components. Thanks to its ergonomic construction, high rapid traverse speed, and its ease of automation, the D2-5AX is ideal for high productivity applications, whether for small or large numbers of units.

D3-5AX

|

Five-axis milling machining centre

HWACHEON

Five-axis milling machining centres

| Workspace |

|

| 900 mm | |

| 775 mm | |

| 600 kg | |

| Travel |

|

| 800 mm | |

| 650 mm | |

| 575 mm | |

| Machine control |

|

| Siemens | |

The compact D3-5AX is designed for use in workshops, education, laboratories and for tool, jig, die and mould making. The D3-5AX has 5 axes as standard, of which 4 can be controlled simultaneously.

Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power of the D3-5AX derive from its heavy machine bed of 16 tonnes, spindles made by Hwacheon and the use of high quality components. Thanks to its ergonomic construction, high rapid traverse speed, and its ease of automation, the D3-5AX is ideal for high productivity applications, whether for small or large numbers of units.

Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power of the D3-5AX derive from its heavy machine bed of 16 tonnes, spindles made by Hwacheon and the use of high quality components. Thanks to its ergonomic construction, high rapid traverse speed, and its ease of automation, the D3-5AX is ideal for high productivity applications, whether for small or large numbers of units.

Vertical machining centres

VESTA-1000+

|

Vertical machining centre with linear guideways and X traverse path 1,000 mm

HWACHEON

Vertical machining centres

| Workspace |

|

| 560 kg | |

| Travel |

|

| 1000 mm | |

| 550 mm | |

| 500 mm | |

| Machine characteristics |

|

| 5040 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

The VESTA-1000+ stands on a grey cast iron bed with a cross table design and is equipped with dynamic linear guideways on all axes. It is characterised by its versatility in different areas of application and its range of configuration options.

The effects of the large distance between guideways can be seen in the high stability and in the dynamics of the machine. A point of focus in the development of the VESTA-1000+ was reliable swarf removal and accessibility for operators. Our own spindle, high performance feed drive and stable guides guarantee repeatable and long-term precision, even in the case of high feed rates and depths of cut.

Main features

Tool magazine with 30 positions

Faster tool changes

Siemens 828D, Fanuc 0i or Heidenhain iTNC 620

Oil-cooled 12,000 rpm (18.5 kW) Hwacheon spindles

Side or rear-mounted swarf conveyor

High ease of operation

Ergonomic table height (950 mm)

Two-part doors to working space

Swivel-mounted control panel

Large windows onto working space glazed with safety glass ensure optimal process observation

Comprehensive software features

Adaptive feed system adjustment (OPTIMA)

Optimised path control (HECC)

Thermal compensation with numerous sensors (HTDC)

Overload control on tool breakage or collision (HTLD)

The effects of the large distance between guideways can be seen in the high stability and in the dynamics of the machine. A point of focus in the development of the VESTA-1000+ was reliable swarf removal and accessibility for operators. Our own spindle, high performance feed drive and stable guides guarantee repeatable and long-term precision, even in the case of high feed rates and depths of cut.

Main features

Tool magazine with 30 positions

Faster tool changes

Siemens 828D, Fanuc 0i or Heidenhain iTNC 620

Oil-cooled 12,000 rpm (18.5 kW) Hwacheon spindles

Side or rear-mounted swarf conveyor

High ease of operation

Ergonomic table height (950 mm)

Two-part doors to working space

Swivel-mounted control panel

Large windows onto working space glazed with safety glass ensure optimal process observation

Comprehensive software features

Adaptive feed system adjustment (OPTIMA)

Optimised path control (HECC)

Thermal compensation with numerous sensors (HTDC)

Overload control on tool breakage or collision (HTLD)

VESTA-1050B

|

Vertical machining centre with box guideways, gear spindle, and X traverse path 1,050 mm

HWACHEON

Vertical machining centres

| Workspace |

|

| 1050 mm | |

| 600 mm | |

| 600 mm | |

| 1000 kg | |

| Travel |

|

| 1050 mm | |

| 600 mm | |

| 600 mm | |

| Machine control |

|

| Fanuc | |

Vertical machining centre with box guideways, gear spindle, and X traverse path 1,050 mm

The VESTA-1050B - ideal for particularly ductile materials and high cutting rates. Thanks to its broad box guideways and solid cast iron body, the VESTA-1050B has ideal stability and damping characteristics, which make the best use of the extraordinarily high torque (up to 840 Nm with Heidenhain controls) of the two-stage gear spindle. With four box guideways on the Y axis, workpieces with a weight of up to one tonne can be cut with ease.

Uncompromising heavy duty cutting with high accuracy over long run times

The VESTA-B series is the result of Hwacheon’s decades of experience: Spindle and drive construction, the manufacture of box guideways and solid machine beds - Hwacheon’s substantial degree of vertical integration makes it possible for any improvements and details to be incorporated into the components. The machine beds are built thermo-symmetrically and optimised by means of FEM inspection in order to minimise thermal distortion. Numerous temperature sensors, our own control software (HTDC) and the oil-cooled gear spindle also reduce heat effects. The VESTA-B series is ideal for hard-to-cut materials and high volumes - with no compromises in accuracy. Uncompromising heavy duty cutting with high accuracy over long run times.

The VESTA-1050B - ideal for particularly ductile materials and high cutting rates. Thanks to its broad box guideways and solid cast iron body, the VESTA-1050B has ideal stability and damping characteristics, which make the best use of the extraordinarily high torque (up to 840 Nm with Heidenhain controls) of the two-stage gear spindle. With four box guideways on the Y axis, workpieces with a weight of up to one tonne can be cut with ease.

Uncompromising heavy duty cutting with high accuracy over long run times

The VESTA-B series is the result of Hwacheon’s decades of experience: Spindle and drive construction, the manufacture of box guideways and solid machine beds - Hwacheon’s substantial degree of vertical integration makes it possible for any improvements and details to be incorporated into the components. The machine beds are built thermo-symmetrically and optimised by means of FEM inspection in order to minimise thermal distortion. Numerous temperature sensors, our own control software (HTDC) and the oil-cooled gear spindle also reduce heat effects. The VESTA-B series is ideal for hard-to-cut materials and high volumes - with no compromises in accuracy. Uncompromising heavy duty cutting with high accuracy over long run times.