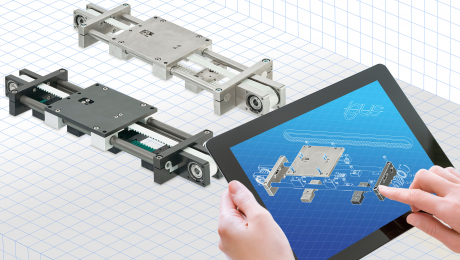

Linear axes variable width and length from igus based on the modular principle

Configure toothed belt axes made of aluminium or stainless steel in desired size

With the new drylin ZLW modular kit the motion plastics specialist igus offers even more versatility and designing freedom for design engineers - widths, rail distances and materials of the ready-to-install axes can be assembled according to your requirement. Thus, high-performance linear axes can be implemented at a low price.

Ready to install, maintenance-free and lubricant-free linear guides are becoming more popular in machine and plant manufacturing. "Off the shelf" solutions that fit exactly to the construction requirements of the user are uncommon To simplify product selection for design engineers, the motion plastics specialist igus has developed a construction kit for its drylin ZLW axes, with which the customers can individually assemble their own solutions. In this modular system, width, rail distances and length of the axes can be adapted quickly and easily. Due to the low profile of the toothed belt axes, even small installation spaces are sufficient for this. In addition, users can order the cross beams, rails and carriages made of aluminium or stainless steel. The latter is of particular interest for applications in the food industry, due to the majority of components being made from stainless steel, this is a unique when considering standard 'off the shelf' items. A maximum service life is possible in combination with liners made of iglidur E7. The linear guides can be supplied with the igus motor or connected to the customer's which enables a variable motor integration to the right and left of the axis by means of solid and hollow shafts.

Now even higher loads and more dynamic applications are possible

Due to the new installation size ZLW-20, loads up to 75 kg can be lifted, with maximum stroke lengths of up to 3,000 millimetres. The wide drive belt also permits high speeds of more than 5 m/s depending on the load. The polyurethane toothed belt with steel cable reinforcement is set centrally on the carriage at the required belt tension. An underwater application is also possible with a special belt. Grooved ball bearings ensure a robust support and greater energy efficiency. A quiet running and a long service life even in continuous operation make the ready to install solutions interesting for numerous applications, such as the most varied handling tasks in the food or laboratory technology. Due to the open design, the linear axes are easy to clean and also insensitive to dirt.

About igus

igus GmbH is a globally leading manufacturer of energy chain systems and polymer plain bearings. The Cologne-based family business has offices in 35 countries and employs around 2,950 people around the world. In 2015, igus generated a turnover of 552 million euros with motion plastics, plastic components for moving applications. igus operates the largest test laboratories and factories in its sector to offer customers quick turnaround times on innovative products and solutions tailored to their needs.

Press Contact

Oliver Cyrus

Head of Media and Advertising

igus® GmbH

Spicher Strasse 1a

51147 Cologne

Tel. 0 22 03 / 96 49-459

Fax +49 22 03 / 96 49-631

[email protected]

www.igus.de/de/presse

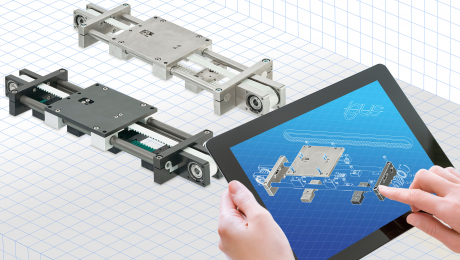

Configure toothed belt axes made of aluminium or stainless steel in desired size

With the new drylin ZLW modular kit the motion plastics specialist igus offers even more versatility and designing freedom for design engineers - widths, rail distances and materials of the ready-to-install axes can be assembled according to your requirement. Thus, high-performance linear axes can be implemented at a low price.

Ready to install, maintenance-free and lubricant-free linear guides are becoming more popular in machine and plant manufacturing. "Off the shelf" solutions that fit exactly to the construction requirements of the user are uncommon To simplify product selection for design engineers, the motion plastics specialist igus has developed a construction kit for its drylin ZLW axes, with which the customers can individually assemble their own solutions. In this modular system, width, rail distances and length of the axes can be adapted quickly and easily. Due to the low profile of the toothed belt axes, even small installation spaces are sufficient for this. In addition, users can order the cross beams, rails and carriages made of aluminium or stainless steel. The latter is of particular interest for applications in the food industry, due to the majority of components being made from stainless steel, this is a unique when considering standard 'off the shelf' items. A maximum service life is possible in combination with liners made of iglidur E7. The linear guides can be supplied with the igus motor or connected to the customer's which enables a variable motor integration to the right and left of the axis by means of solid and hollow shafts.

Now even higher loads and more dynamic applications are possible

Due to the new installation size ZLW-20, loads up to 75 kg can be lifted, with maximum stroke lengths of up to 3,000 millimetres. The wide drive belt also permits high speeds of more than 5 m/s depending on the load. The polyurethane toothed belt with steel cable reinforcement is set centrally on the carriage at the required belt tension. An underwater application is also possible with a special belt. Grooved ball bearings ensure a robust support and greater energy efficiency. A quiet running and a long service life even in continuous operation make the ready to install solutions interesting for numerous applications, such as the most varied handling tasks in the food or laboratory technology. Due to the open design, the linear axes are easy to clean and also insensitive to dirt.

About igus

igus GmbH is a globally leading manufacturer of energy chain systems and polymer plain bearings. The Cologne-based family business has offices in 35 countries and employs around 2,950 people around the world. In 2015, igus generated a turnover of 552 million euros with motion plastics, plastic components for moving applications. igus operates the largest test laboratories and factories in its sector to offer customers quick turnaround times on innovative products and solutions tailored to their needs.

Press Contact

Oliver Cyrus

Head of Media and Advertising

igus® GmbH

Spicher Strasse 1a

51147 Cologne

Tel. 0 22 03 / 96 49-459

Fax +49 22 03 / 96 49-631

[email protected]

www.igus.de/de/presse