New maintenance dashboard celebrates its premiere at EMO Hannover

ILT brings IoT to extraction technology: New maintenance dashboard celebrates its premiere at EMO Hannover

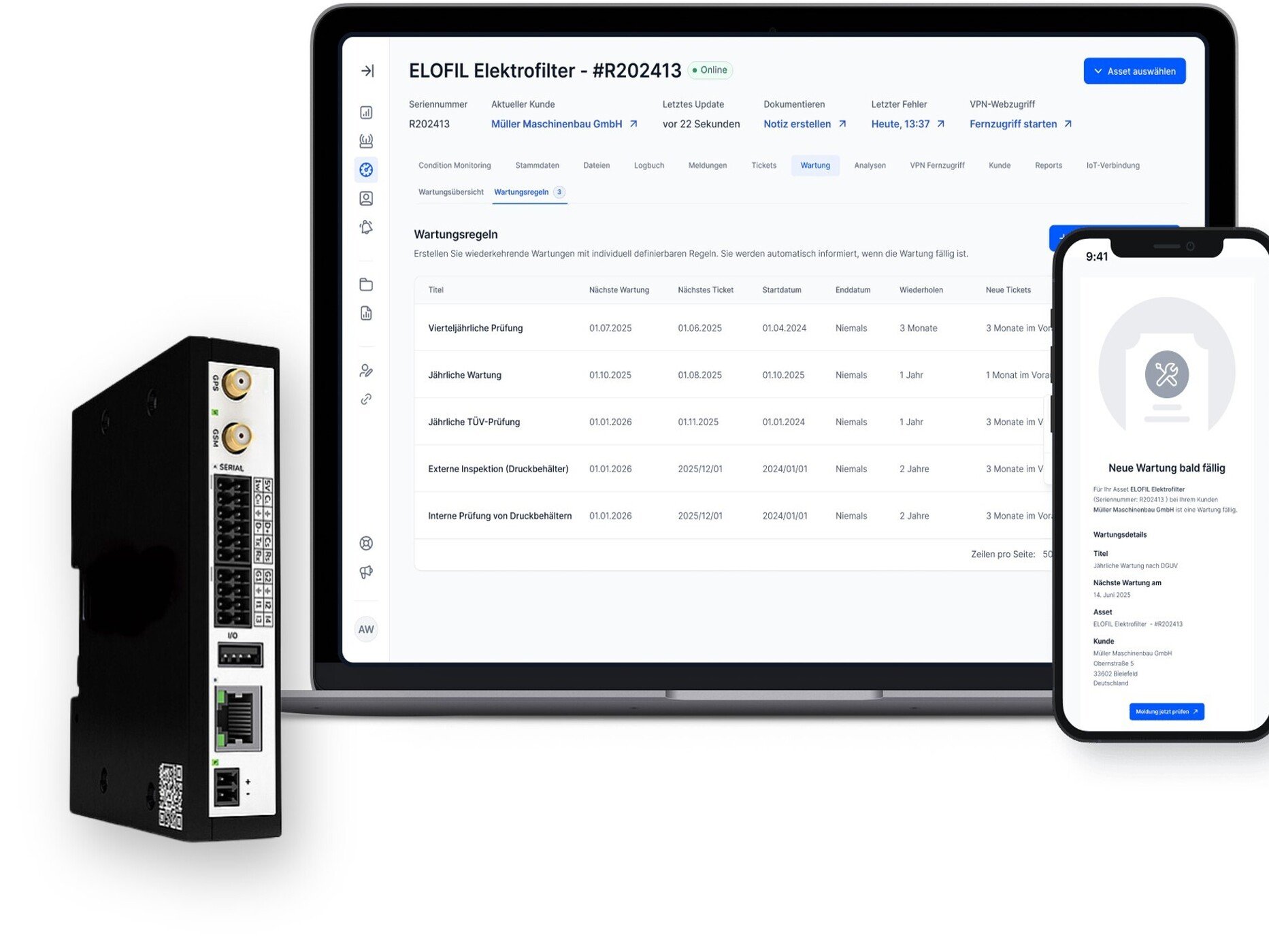

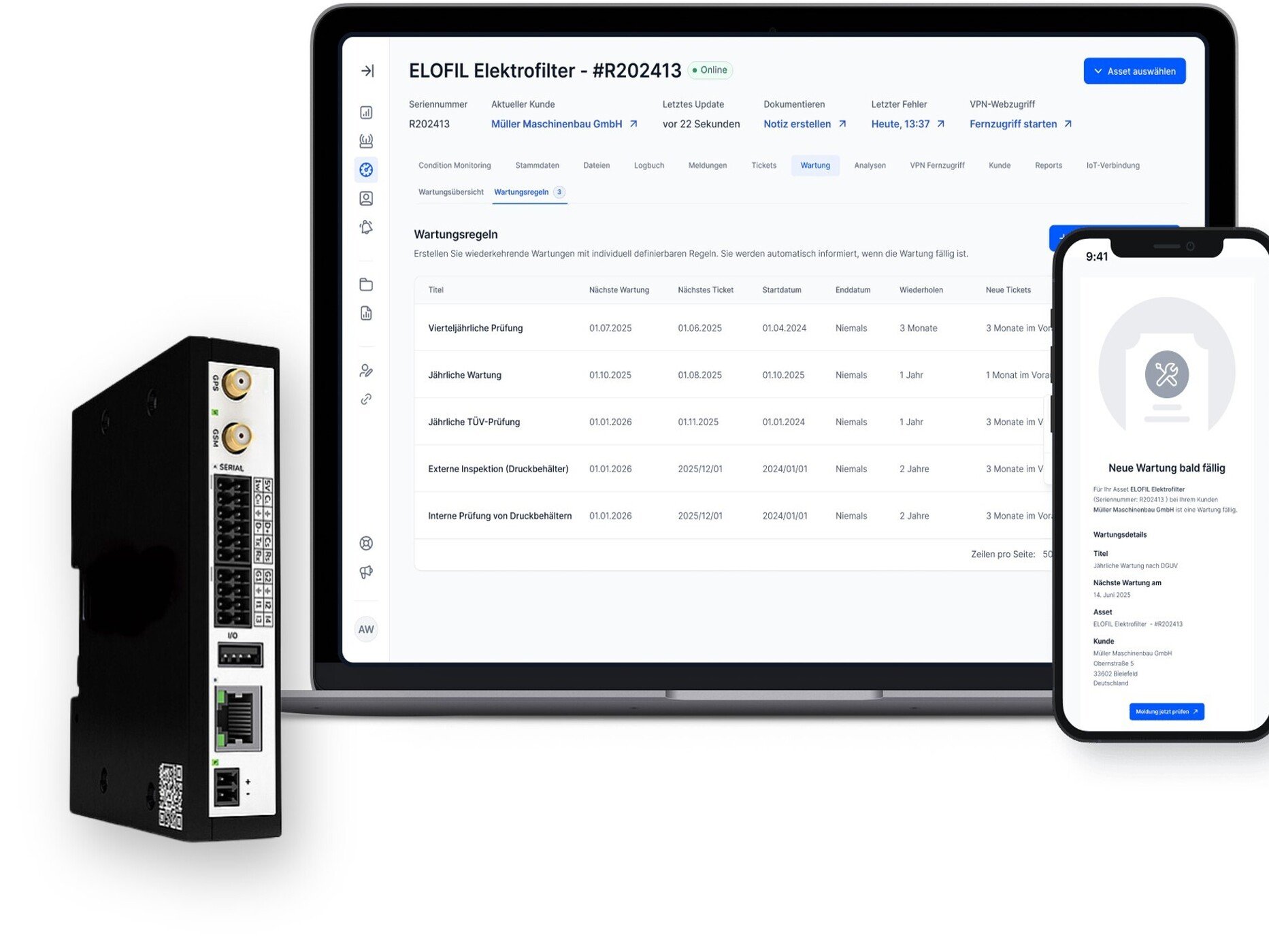

Ruppichteroth, September 2025 – ILT Industrie-Luftfiltertechnik GmbH is presenting a real industry innovation at this year's EMO Hannover: an IoT-based maintenance and operating management system for industrial extraction systems. With the new ILT maintenance dashboard, the digital transformation in extraction technology is becoming a reality – a milestone for greater efficiency, transparency, and operational safety.

While IoT solutions are already established in areas such as compressed air technology and machine control, ILT is breaking new ground in industrial air filter technology with this development. The system enables continuous monitoring of all relevant system data, demand-based maintenance planning, and secure remote access – all in a user-friendly, mobile-optimized platform.

Real-time transparency – for maximum system availability

The ILT maintenance dashboard collects and analyzes operating data such as air volume flows, filter statuses, energy consumption, running times, and fault messages in real time. This information is transmitted in encrypted form via a secure IoT gateway and is available to the operator at all times – whether in the office, in production, or on the road.

The platform not only offers live visualization of plant conditions, but also a complete data history. This enables a well-founded analysis of trends, deviations, and optimization potential – a decisive advantage for maintenance and energy management teams.

Maintenance reimagined: proactive instead of reactive

A central element of the system is predictive maintenance. Through intelligent evaluation of operating data, the dashboard recognizes early on when maintenance measures are necessary – even before failures or performance losses occur. This enables precise planning of service calls, reduces unplanned downtime, and extends the service life of plant components.

The system sends automated notifications to the responsible persons as soon as defined thresholds are reached. This allows spare parts to be procured in good time and maintenance appointments to be coordinated efficiently – in line with modern, resource-saving plant operation.

Secure remote access and easy integration

At the heart of the solution is the ILT ConnectBox, a certified IoT gateway with an integrated SIM card for all mobile networks. Data is transmitted in encrypted form in accordance with the highest security standards – without access to the company network. The system is fully GDPR- -compliant and can be retrofitted to both new and existing extraction systems.

Remote access enables ILT service technicians to provide fast and efficient support when needed – often without having to visit the site. This saves time, reduces costs, and increases response speed in the event of a malfunction.

Premiere at EMO Hannover 2025

EMO Hannover, one of the world's leading trade fairs for production technology, provides the ideal setting for the presentation of this innovation. At the ILT booth, visitors can experience the new maintenance dashboard live, talk to the developers, and discuss individual applications for their systems.

A strategic step towards Industry 4.0

With the new maintenance dashboard, ILT is underlining its role as a technology leader in industrial air filter technology. The solution is a central building block on the path to digitized, networked, and sustainable production—and a strong signal to customers who want to make their processes future-proof.

"We see the digitalization of extraction technology not only as a technical upgrade, but as real added value for our customers. The new dashboard is an important step toward smarter, more efficient, and more sustainable production environments," says Falco Riemer, Managing Director of ILT.

About ILT Industrial Air Filter Technology

ILT has been a specialist in industrial extraction technology for over 40 years. With innovative solutions for clean air in the workplace, ILT supports companies in industry, trade, and research – from planning and manufacturing to maintenance.

For more information, visit: www.ilt.eu

ILT brings IoT to extraction technology: New maintenance dashboard celebrates its premiere at EMO Hannover

Ruppichteroth, September 2025 – ILT Industrie-Luftfiltertechnik GmbH is presenting a real industry innovation at this year's EMO Hannover: an IoT-based maintenance and operating management system for industrial extraction systems. With the new ILT maintenance dashboard, the digital transformation in extraction technology is becoming a reality – a milestone for greater efficiency, transparency, and operational safety.

While IoT solutions are already established in areas such as compressed air technology and machine control, ILT is breaking new ground in industrial air filter technology with this development. The system enables continuous monitoring of all relevant system data, demand-based maintenance planning, and secure remote access – all in a user-friendly, mobile-optimized platform.

Real-time transparency – for maximum system availability

The ILT maintenance dashboard collects and analyzes operating data such as air volume flows, filter statuses, energy consumption, running times, and fault messages in real time. This information is transmitted in encrypted form via a secure IoT gateway and is available to the operator at all times – whether in the office, in production, or on the road.

The platform not only offers live visualization of plant conditions, but also a complete data history. This enables a well-founded analysis of trends, deviations, and optimization potential – a decisive advantage for maintenance and energy management teams.

Maintenance reimagined: proactive instead of reactive

A central element of the system is predictive maintenance. Through intelligent evaluation of operating data, the dashboard recognizes early on when maintenance measures are necessary – even before failures or performance losses occur. This enables precise planning of service calls, reduces unplanned downtime, and extends the service life of plant components.

The system sends automated notifications to the responsible persons as soon as defined thresholds are reached. This allows spare parts to be procured in good time and maintenance appointments to be coordinated efficiently – in line with modern, resource-saving plant operation.

Secure remote access and easy integration

At the heart of the solution is the ILT ConnectBox, a certified IoT gateway with an integrated SIM card for all mobile networks. Data is transmitted in encrypted form in accordance with the highest security standards – without access to the company network. The system is fully GDPR- -compliant and can be retrofitted to both new and existing extraction systems.

Remote access enables ILT service technicians to provide fast and efficient support when needed – often without having to visit the site. This saves time, reduces costs, and increases response speed in the event of a malfunction.

Premiere at EMO Hannover 2025

EMO Hannover, one of the world's leading trade fairs for production technology, provides the ideal setting for the presentation of this innovation. At the ILT booth, visitors can experience the new maintenance dashboard live, talk to the developers, and discuss individual applications for their systems.

A strategic step towards Industry 4.0

With the new maintenance dashboard, ILT is underlining its role as a technology leader in industrial air filter technology. The solution is a central building block on the path to digitized, networked, and sustainable production—and a strong signal to customers who want to make their processes future-proof.

"We see the digitalization of extraction technology not only as a technical upgrade, but as real added value for our customers. The new dashboard is an important step toward smarter, more efficient, and more sustainable production environments," says Falco Riemer, Managing Director of ILT.

About ILT Industrial Air Filter Technology

ILT has been a specialist in industrial extraction technology for over 40 years. With innovative solutions for clean air in the workplace, ILT supports companies in industry, trade, and research – from planning and manufacturing to maintenance.

For more information, visit: www.ilt.eu