Hi !

Noticed problem as can be seen , puzzles us right now.....

https://www.youtube.com/watch?v=OJ7uYXR0xwM

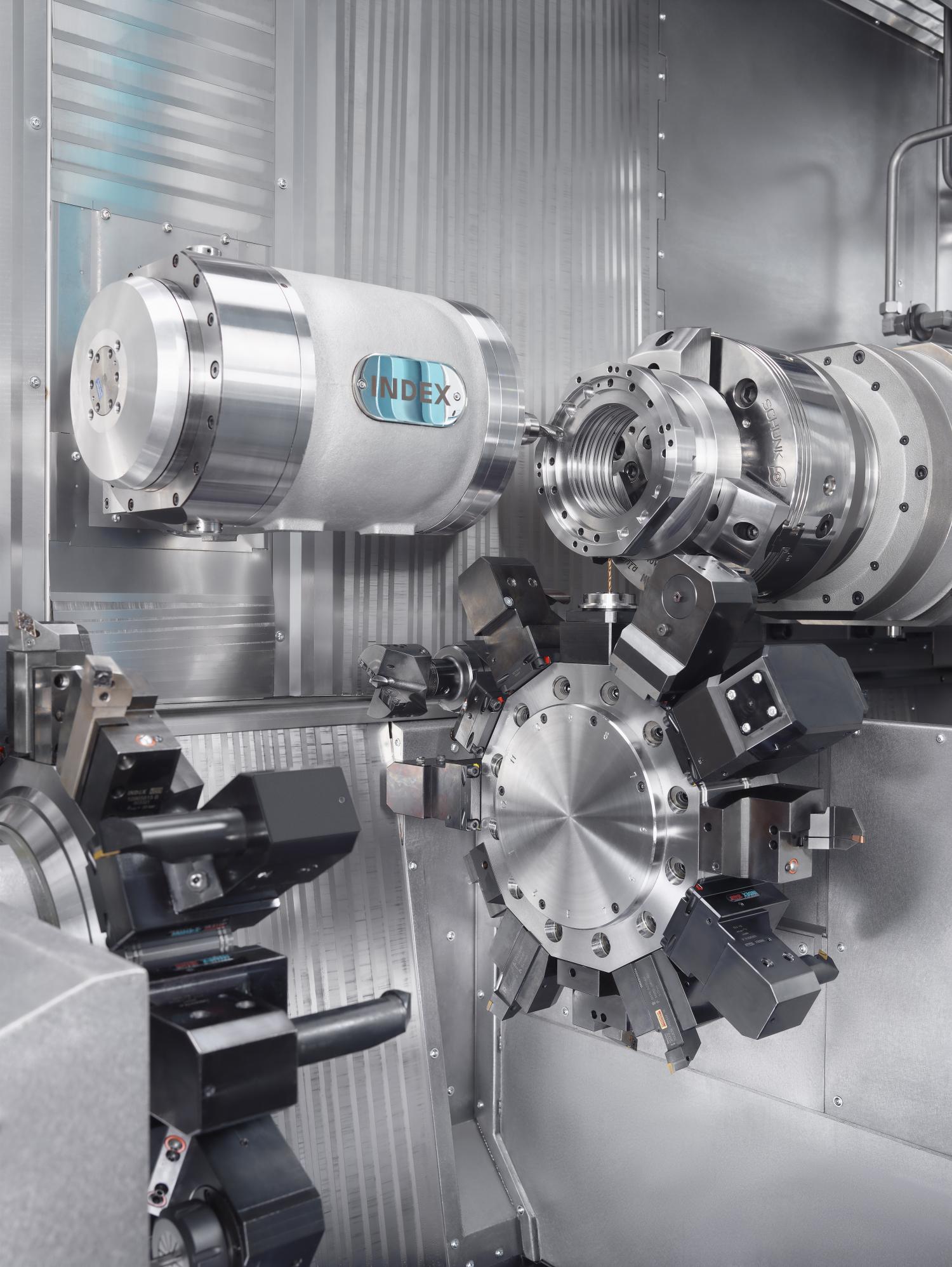

INDEX

Forum

Thread: Spinle or holder problem ?

Results 1 to 3 of 3

-

01-28-2014, 10:04 PM #1

Spinle or holder problem ?

FADAL VMC4020 HT 1995, Z 28" (if true) , 88HS , 10K rmp , 21 TC geneva /rotary/ , VH-65 (A-axis) ,3ph 400V , metric, NO conveyor, No palette. (+alternative DC AMP)

-

01-28-2014, 10:12 PM #2Member

- Join Date

- Feb 2009

- Posts

- 6028

You sure the tool can go in 180 deg off without hitting the drive dogs.

-

01-31-2014, 11:28 AM #3Registered

- Join Date

- Jul 2013

- Posts

- 12

Hi.

Put the clock against the spindle bore and see if it's correct, if so the problem is in the holder-Haimer

If you rotate the Haimer probe in the tool holder 180 deg and it behaves exactly the same then the Haimer is correct and the holder isn't.

If the problem is in the holder then you have corected this when you zero adjust the Haimer, and the correction you did will if the holder is rotated 180 deg be an error twice as large as the error you corrected in the first place.

Hope this helps.

//

Fredrik

Similar Threads

-

miyano BNC-34S parameters twin spinle single turret lathe

By mr pitt in forum FanucReplies: 10Last Post: 05-04-2023, 11:04 AM -

Problem with Duality Lathe Tool Post Holder Alignment

By anglin in forum Tormach Personal CNC MillReplies: 2Last Post: 11-14-2011, 04:09 AM -

emco 5 CNC tool holder problem

By sparkymike in forum EMCO LatheReplies: 8Last Post: 05-06-2010, 07:23 PM -

AM HAVING PROBLEM WITH THE CUTTER HOLDER

By musa68 in forum Printing, Scanners, Vinyl cutting and PlottersReplies: 0Last Post: 01-18-2009, 04:43 PM -

X2 spinle undersized?

By AirHog in forum X3/SX3/G0619/G0463Replies: 3Last Post: 02-19-2007, 01:09 AM

Reply With Quote

Reply With Quote