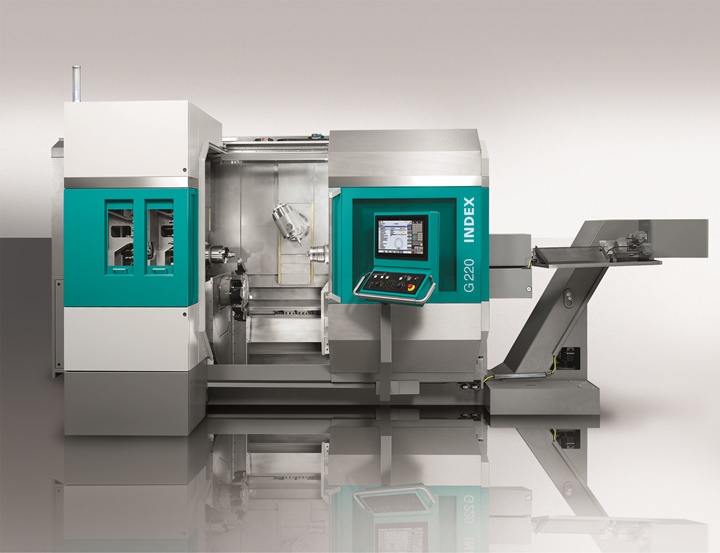

The new G-Generation. Turn-Mill Center INDEX G220

Prepared for the future.

The INDEX G220 Turn-Mill Center continues the tradition of the company’s successful, compact G-series – now completely redesigned inresponse to market requirements, the growing complexity of components and falling batch sizes. Thanks to a motorized milling spindle capable of five-axis milling and a tool turret with Y-axis, the G220 operates with great flexibility and can execute virtually any turning or milling machining process.

The development engineers at INDEX have contributed their full experience from the R and G machine series in the new design of the G220.

The result is a compact machine which performs typically high-quality turning and five-axis milling with a footprint of approximately 10 m2 (excluding bar loader).

It is based on a heavily rubbed cast iron machine bed which, together with the generously sized linear guides in the X and Z-axes, ensures excellent stability and damping properties.

With a distance of 1280 mm between the main and counter spindle and a maximum turning length of 1000 mm, the G220 turn-mill center offers a spacious work area. All components of relevance to the machine operator, i.e. the main and counter spindles, the turret and the motorized milling spindle, but also the machine’s operating panel, are located within an “ergonomic belt”, as INDEX calls the area marked in turquoise on the machine enclosure and which is ergonomically easily accessible to the machine operator.

The main and counter spindles are designed identically, are fluid-cooled and feature a clearance of 65 mm (chuck up to max. 250 mm diameter). They make possible productive turning machining with a power of 20/ 24 kW (100%/40%), a torque of 135/ 190 Nm and a maximum speed of 5000 rpm.

The spindle center is located 1350 mm above the ground. A tool turret is located in the lower part of the machine. Here, customers can select between VDI 25 and VDI 30 tool mountings and a corresponding 18 or 12 stations, all of which can be equipped with individually driven tools (power 6 kW, torque 18 Nm, speed 7200 rpm).

The five-axis motorized milling spindle (power 11 kW, torque 30 Nm, speed up to 18000 rpm) is fluid-cooled and has hydrostatic bearings in the Y/B-axes. The stable circular guide further ensures excellent rigidity and damping. The Y-axis features a +/-80 mm stroke, the B-axis driven directly by a torque motor has a swivel range of -35 to +215 degrees. With a large travel distance in the X-direction, machining at up to 30 mm below the turning center height is possible.

The motorized milling spindle operates using a one or optionally two-row tool chain magazine which features space for 70 or 140 tools (HSK-A40). The stations feature a tilting basket design which protects the tools against contamination from oil and chips.

Users particularly benefit from the double-row tool magazine, which enables setup during main time, as well as from the integrated drill breakage monitoring unit which employs a light barrier to automatically check if the tool is still fully available every time a tool change is performed.

The available peripherals – from the machine’s cooling concept or the integrated workpiece removal all the way to the new MBL bar loader (option) – are also extremely well thought out. In order to dissipate the heat produced in the fluid-cooled spindles and the control cabinet, INDEX has integrated a hydraulic circuit with interface which enables connection to a decentralized cooling unit or a central cooling system.

Almost all commonly available bar loading magazines can be connected to the G220 turn-mill center. The new version of the INDEX bar loading magazine MBL (option), however, offers the specific advantage of guiding the bars in roller bearings. Irrespective of the bar speed, this results in an extremely precise and low-vibration bar guide. The INDEX MBL is suitable for bars of up to 65 mm diameter and a length of optionally 3200 mm or 4200 mm.

The INDEX G220 features a CNC-controlled and CNC-programmable gantry-type removal unit for gentle removal of finished workpieces. It can unload both remnants from the main spindle and finished parts from the counter spindle.

The G220 presents a particular highlight when it comes to user friendliness and process reliability with the latest generation of the INDEX C200 SL controller. It is based on the Siemens Sinumerik 840D sl (solution line) and features an 18.5" touch screen. The user interface is integrated in the NC core and does not require a Windows PC.

The use of the latest capacitive touch technology – which can be used even when wearing gloves – makes it possible to incorporate numerous rotary and touch buttons of the machine control panel directly in the screen. A touch with the finger is sufficient to activate functions. Buttons and switches available for selection, that apply to the current machine status and whose movements are released are selectively backlit, while illegal ones are dimmed. Flashing keys must be enabled by the operator, who is thus guided through operations and can prevent errors.

The operating panel can, however, do more than just operate the machine. It features a second input which INDEX uses for its own Virtual Machine (VM) (option). By pressing a button, the operator can switch to “VM on Board” and make use of simulation, irrespective of current machine operations. The control technology’s network integration also presents new functions such as “CrashStop”, which enables predictive simulation of the workpiece program running on the machine. The machine program can be simulated without interruption using “RealTime”. Another new feature is IT-FIT, the INDEX-TRAUB factory information technology with which the machine operator can call up information from the company network.