INDEX-Werke // INDEX TRAUB

ProductsB400

|

Universal lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal lathes

CNC lathe B400. universal turning at the highest level. Spindle passage with 82 mm 315 mm chuck diameter 750 mm turning length - Clearly structured and ergonomic workspace concept - Rigid mineral casting bed in 45° monoblock design for high accuracies - Work spindle with belt drive for high torques - Bar capacity ø 82 mm, chuck up to ø 315 mm - orthogonal, linear Y-axis for high accuracy - NC tailstock with electronically controllable axis - Already included: The operating system iXpanel - i4.0 ready with 18.5" touch- screen - basis: Siemens S840Dsl Translated with DeepL

B500

|

Universal lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal lathes

The B500. Universal turning at the highest level. Spindle passage with 102 mm 400 mm chuck diameter 750 mm turning length - Clearly structured and ergonomic workspace concept - Rigid mineral casting bed in 45° block design for high accuracies - Work spindle with belt drive for high torques - Bar capacity ø 102 mm, chuck up to ø 400 mm - orthogonal, linear Y-axis for high accuracy - NC tailstock with electronically controllable axis - Already included: The operating system iXpanel - i4.0 ready with 18.5" touch- screen - basis: Siemens S840Dsl Translated with DeepL

TNA500

|

Universal lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal lathes

The CNC universal lathe TNA500 - The value for money. The right machine for the toughest production use. Spindle passage with 102 mm 400 mm chuck diameter 750 mm turning length - Rigid mineral cast bed in 45° block design for high accuracies - Working spindle A11 with belt drive for high torques - Spindle diameter Ø 102 mm, chuck up to Ø 400 mm - Generously designed bed guides - Star turret for 12 tools with VDI 40 mounting and W-toothing for high process reliability or disc turret for 12 tools with VDI 40 mounting - Orthogonal, linear Y-axis for high accuracy - Large axis strokes X 245 mm / Y ±60 mm / Z 750 mm Translated with DeepL

TNA400

|

Universal lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal lathes

The all-rounder in universal turning - The TNA400 universal turning machine ensures powerful cutting and comprehensive machining options. Spindle clearance: 80 mm Chuck diameter: 200 - 315 mm Turning length: 750 mm - Y-axis with 100 mm travel - 50 mm turret face travel over spindle center for optimal use of tools - Tailstock on separate guideway - 12-station disk-type turret with individual drive at all stations - Hydraulic power clamping device - Internal coolant supply with 5 bar - Chip conveyor

INDEX C100

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Automatic lathe - for faster machining. Optimal for bar machining and complex workpieces. Spindle passage with 42 mm 110 mm chuck diameter 400 mm turning length - Simultaneous machining with 2 or 3 turrets - High acceleration (1g) and high rapid traverse rates (60 m/min) - Tool carrier with Y-axis available on main and counter spindle - 2 powerful, identical motor spindles - Very good vibration damping due to INDEX SingleSlide - Maximum part variety due to 3 turrets and 42 tools - The controls Siemens S840D sl (18.5" touch screen ) or Fanuc 31i-B (18.5" touch screen) offer economical and productive solutions at any time. solutions - Already included: The iXpanel operating system - i4.0 ready Translated with DeepL

C200

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Production lathe for highly productive bar machining.

The INDEX C200 - a turning machine for complex workpieces.

Spindle diameter 65 (90) mm

160 mm Chuck diameter

550 mm Turning length

- Fast production of bar turned parts

- Generous working area for complete machining of workpieces

- The INDEX SingleSlide guide system ensures significantly

higher dynamics

- High acceleration (1g) and high rapid traverse rates (60 m/min)

- 2 powerful, identical motor spindles

- The controls Siemens S840D sl (18.5" touch screen) or Fanuc

31i-B (15" touch screen) offer economical and productive solutions at any time.

utions

- Already included: The iXpanel operating system - i4.0 ready

Translated with DeepL

INDEX ABC

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Dynamic production lathe. Unsurpassed power density - high dynamics. Spindle passage with 65 mm 6,000 min-1 Speed max. 27 kW Power max. 145 Nm Torque max. - Y-axis functionality for surface milling and off-center drilling - Multiple machining options due to multiple assignment of the tool stations tool stations possible - Piece time reduction due to a highly dynamic working spindle and simultaneous machining with up to 3 tools - Driven tools can be used on all tool carriers - Up to 5 rear machining stations - High repeatability and ease of setup due to INDEX W toothing - The controls Siemens S840D sl (18.5" touch screen) or Fanuc 31i-B (15" touch screen) offer economical and productive solutions at any time. solutions - Already included: The iXpanel operating system Translated with DeepL

INDEX MS16-6 / MS16-6 Plus

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Dynamic multispindle machine. Shortest changeover times, highest dynamics and lowest non-productive times define lowest workpiece costs. Spindle passage with 16 / 22 mm 10,000 min-1 Speed max. 15 kW Power max. 18 Nm Torque max. - Infeed slide for highest cutting performance at shortest machining times - spindle drum with individual drives of the working spindles - Cross slide for flexible complete machining - CNC parting slide with extended stroke for backworking - Highly dynamic synchronous spindle with extremely short acceleration and deceleration times - Fast tool setup due to INDEX W-toothing - Up to 22 mm spindle clearance with MS16-6 Plus - Already included: The operating system iXpanel - i4.0 ready with 18.5" touch screen and control Siemens S840D sl Translated with DeepL

INDEX MS22-8

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Productive multispindle machine with 8 spindles. 8 main spindles, up to 2 swivel synchronous spindles and up to a maximum of 16 tool carriers. Spindle capacity with 22 (24) mm 10,000 min-1 Speed max. 15 kW Power max. 18 Nm Torque max. - Highly dynamic slides with sliding guide (X-axis) - Wear-free Z-axis due to quills with hydrostatic bearings - Chuck part machining with loading and unloading by robot - Up to 16 tool carriers with 1 or 2 traversing axes and optional Y-axis can be used variably - Versatility is the strength of the MS22-8. Whether complicated parts or different processes - everything is possible. - More options for backworking with hydraulically locked and extremely fast swiveling synchronous spindle. - Already included: The iXpanel operating system - i4.0 ready with 18.5" touch screen and Siemens S840D sl Translated with DeepL

INDEX MS24-6

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Front-opening multispindle machine for bar turned parts. Precision, speed and flexibility. Spindle opening with 24 mm 10,000 min-1 Speed max. 15 kW Power max. 18 Nm Torque max. - front-opening machine for bar machining - Six high-precision motor spindles - freely accessible and therefore extremely user-friendly - highly dynamic slides with sliding guide (X-axis) - wear-free Z-axis, as the quills are mounted hydrostatically - Backworking by synchronous spindle - Including iXpanel cockpit solution (based on Siemens S840D sl) Translated with DeepL

INDEX MS32-6

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

CNC multi-spindle automatic lathe for high productivity and short cycle and setup times. A development for the application of state-of-the-art manufacturing technologies. Spindle passage with 32 mm 8,000 min-1 Speed max. 19 kW Power max. 40 Nm Torque max. - Highly dynamic slides with sliding guide (X-axis) - Wear-free Z-axis due to hydrostatically mounted quills - Grooving and drilling slides for highest cutting performance at shortest machining times - Front-opening machine for bar machining - Chuck part machining with loading and unloading by robot - Quick tool set-up by INDEX quick clamping system with W-toothing - Up to 6 tools for backworking per swiveling synchronous spindle - Already included: The operating system iXpanel - i4.0 ready with 18.5" touch screen and Siemens S840D sl Translated with DeepL

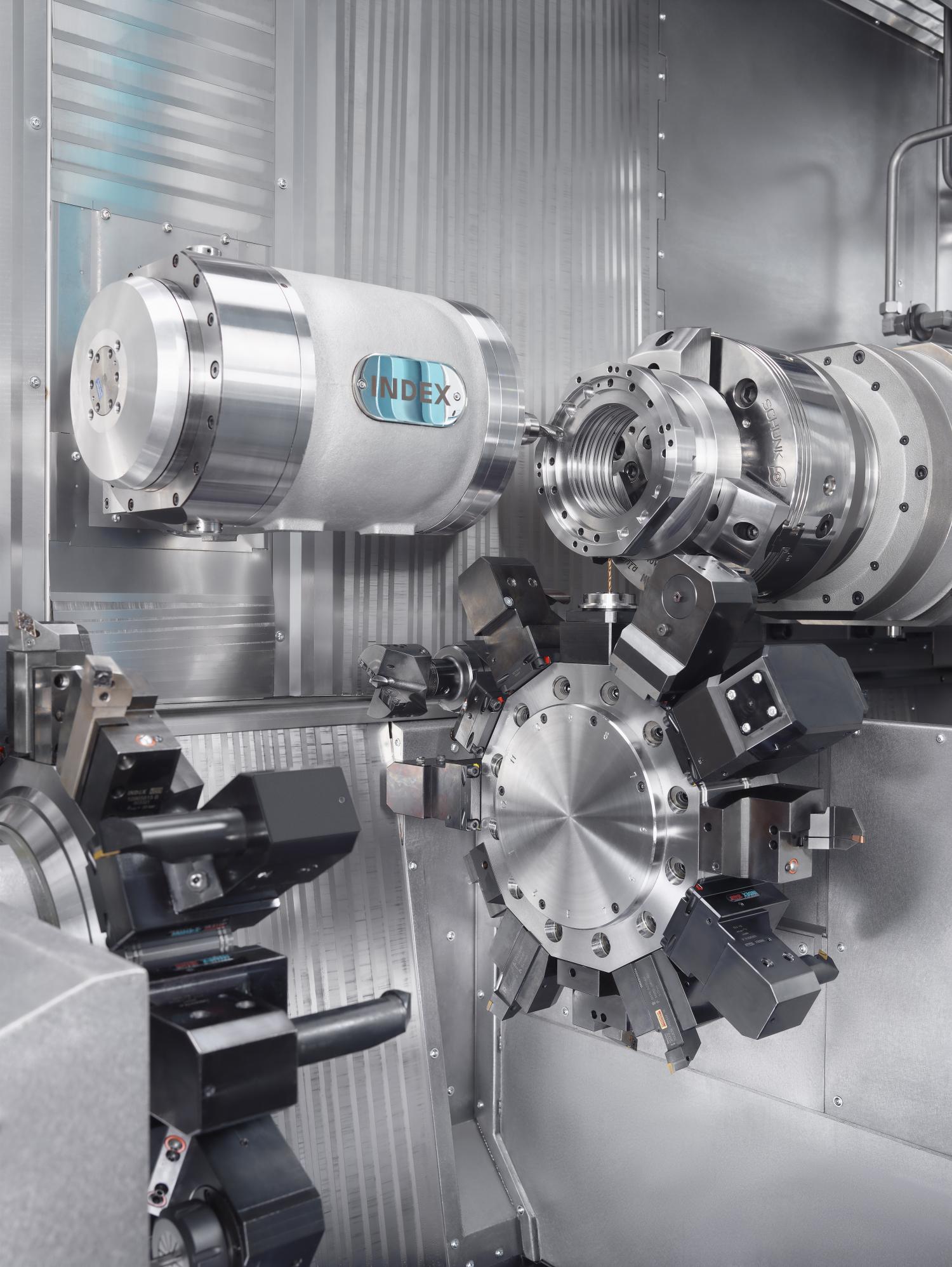

INDEX MS40-8

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

INDEX CNC Multi-Spindle Machine MS40-8: More productive with 8 spindles! Designed exactly to the user's requirement. Spindle capacity with 40 mm 7,000 min-1 Speed max. 24 kW Power max. 57 Nm Torque max. - Highly dynamic slides with sliding guide (X-axis) - Wear-free Z-axis due to hydrostatically mounted quills - Freely accessible working area and therefore extremely setup-friendly - Chuck parts machining with loading and unloading by robot - Directed part removal by linear handling - Extremely fast swivel synchronous spindles with C-axis for rear-side machining - Swivel arm is locked in the machining position with three-part Hirth gearing, thus ensuring maximum rigidity Translated with DeepL

INDEX MS52-6

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Multi-spindle machine with innovative backworking - A development for the latest production technologies Spindle throughput with 52 mm 5,000 min-1 Speed max. 30 kW Power max. 130 Nm Torque max. > Highly dynamic slides with sliding guide (X-axis) > Wear-free Z-axis due to hydrostatically mounted quills > Chuck part machining with loading and unloading by robot or linear handling > Äußonly fast swivel synchronous spindles with C-axis > Swivel arm is locked in the machining position with three-part Hirth coupling and thus ensures maximum rigidity > Maximum of 6 tools for backworking per swivel synchronous spindle > Already included: The iXpanel operating system - i4.0 ready with 18.5" touch screen and Siemens S840D sl

Translated with DeepL

MS40-6

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

CNC multispindle machine MS40-6: The benchmark! A machine concept that meets all requirements and the highest demands. Spindle passage with 40 mm 7,000 min-1 Speed max. 24 kW Power max. 57 Nm Torque max. - Highly dynamic slides with sliding guide (X-axis) - Wear-free Z-axis due to hydrodynamically mounted quills - Front-opening machine for bar machining - Chuck part machining with loading and unloading by robot or linear handling - Swivel arm is locked in the machining position with three-part Hirth gearing for maximum rigidity - Maximum of 6 tools for backworking per swivel synchronous spindle - Already included: The operating system iXpanel - i4.0 ready with 18.5" touch screen and Siemens S840D sl Translated with DeepL

TNL12

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

TNL12 - The sliding headstock automatic lathe. Compact long and short automatic lathe for the precise machining of small workpieces. Spindle opening with 13 mm 12.000 min-1 Speed max. 130 mm max. Z-travel > Bar passage up to ø 13 mm > Up to four tool carriers for simultaneous tool use > High tool stock for setup-friendly production > Simple changeover from sliding headstock to short turning operation > Very compact machine design for high productivity per unit area > Short tool change times due to CNC indexing axis in the tool turrets, front attachment and back attachment Translated with DeepL

TNL20

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

The TRAUB TNL20 - an extremely powerful automatic sliding headstock lathe. Productive long turning and short turning for workpieces of medium and high complexity from the bar or with integrated robot cell. Spindle opening with 20 mm 10,000 min-1 Speed max. 205 mm Z-travel sliding headstock lathe max > Simultaneous machining with 2, 3 or 4 tools > High tool stock for setup-friendly production Easy changeover between long and short turning operation > Short tool change times due to CNC indexing axes in the tool turrets and front attachment > Generously dimensioned and process-safe work area > Intelligent automation through integration of the iXcenter robotic cell Translated with DeepL

TNL32

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

TNL32 sliding headstock automatic lathe - Compact. Precise. Fast. Three variants with measurable advantages for your production. Spindle capacity with 32 mm 8,000 min-1 Speed max. 305 mm Z-path Sliding headstock lathe max. > simultaneous machining with up to 3 tools (each tool with variable feed) > clearly structured work area with large axis travels and large tool flight circles > excellent traction äexcellent traction thanks to a large sliding hood > easy changeover between long and short turning operation > very compact machine design with low space requirement > maximum precision thanks to thermo-symmetrical machine design > DualDrive: New tool drive system from TRAUB

Translated with DeepL

Gebrauchte CNC Drehmaschinen

|

Universal automatic lathe

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Universal automatic lathes

Used CNC lathes - as good as new!

Our used machines are modernized by our qualified employees and their decades of experience in mechanical engineering. Assemblies are usually completely disassembled, cleaned and repainted as required.

The inner life undergoes a "fresh cell cure". Wearing parts, guide elements, fluid-carrying lines, sensors and cables in the machine room are replaced, working and milling spindles are overhauled in proven manufacturer quality and the control technology is brought up to date.

Each CNC lathe reconditioned by us is thus in no way inferior to a new machine in terms of precision.

Translated with DeepL

G200.2

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

The INDEX G200. Flexible turning and milling - as productive as automatic turning. The next generation of the turn-mill center with more performance on the smallest footprint. Spindle passage with 65 mm 165 mm chuck diameter 660 mm turning length - Up to 3 tool carriers with Y-axis on main spindle and counter spindle can be used - Simultaneous machining with up to 4 tools at the same time - Powerful and dynamic milling spindle (360 degree B-axis, max. 7,200 min-1, 22 kW & 52 Nm) - Economical complete machining of workpieces of both bar stock as well as chuck parts - Incomparably large degrees of freedom in the spacious work area designed for turning milling with up to 660 mm turning length - Very good ergonomics for short set-up times - Small footprint and high power density Translated with DeepL

G200.3/ G220

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

The G200.3/ G220 Turning-Milling Centers for High Productivity and Flexibility Turning and milling in new dimensions. Spindle passage with 76 mm 230 mm chuck diameter 207 Nm torque 900 mm turning length - Identical main and counter spindle with spindle passage Ø 76 mm - Chuck up to maximum Ø 230 mm - 3 tool carriers for up to 169 tools - Powerful motorized milling spindle with proven Y/B quill kinematics for complex 5-axis milling operations (G220) - Sophisticated work area concept for turning lengths up to 900 mm and variable machining possibilities - High thermal and mechanical stability - High dynamics (rapid traverses up to 50 m/min) - High set-up friendliness - Mechanical engineering "Made in Germany Translated with DeepL

G300/ G320

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

The G300/ G320 turning/milling centers for high-performance machining of medium-sized workpieces. Turning and milling in new dimensions. Spindle diameter with 102 mm 250 mm chuck diameter 1400 mm turning length - Identical main and counter spindle with spindle passage Ø 102 mm - Chuck up to maximum Ø 250 mm (Ø 315 mm) - 3 tool carriers for up to 141 tools - Powerful motorized milling spindle with proven Y/B quill kinematics for complex 5-axis milling operations (G320) - Sophisticated work area concept for turning lengths up to 1,400 mm and variable machining possibilities - High thermal and mechanical stability - High dynamics (rapid traverses up to 50 m/min) - Mechanical engineering "Made in Germany Translated with DeepL

G400/ G420

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

The innovative G400/ G420 turning/milling center-for high-performance complete machining of large workpieces. Turning and milling in new dimensions. Spindle passage with 120 mm 400 mm chuck diameter 1,000 Nm Torque 1,600 / 2,300 mm turning length - Identical main and counter spindle with spindle passage Ø 120 mm - Chuck Ø 400 mm - Tool storage for up to 139 tools (INDEX G420) - Sophisticated work area concept for turning lengths up to 1,600 mm / 2,300 mm and variable machining possibilities - High thermal and mechanical stability - High dynamics (rapid traverses up to 50 m/min) - Chip conveyor can be used on the left and right Translated with DeepL

G500/ G520

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

The innovative G500/ G520 turning and milling center - for high-performance complete machining of large workpieces. Turning and milling in new dimensions. Spindle passage with 120 mm 500 mm chuck diameter 2,000 Nm Torque 1,600 / 2,300 mm turning length - Identical main and counter spindles with spindle passage Ø 120 mm - Chuck Ø 500 mm - Tool storage for up to 139 tools (INDEX G520) - Sophisticated work area concept for turning lengths up to 1.600 mm / 2,300 mm and variable machining options - High thermal and mechanical stability - High dynamics (rapid traverse rates up to 50 m/min)

Translated with DeepL

R200

|

Turning and milling centre

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Turning and milling centres

Turning and milling center R200 - simply convincing. Increased productivity thanks to two independent subsystems with full 5-axis capability. Spindle throughput with 65 mm 5,000 rpm speed 24 kW power max. 190 Nm max. torque - 5-axis machining on the front and rear of the workpiece enables an extremely wide variety of parts - A total of 12 fixed turning tools for particularly high rigidity and cutting performance - High cutting volume thanks to powerful motorized milling spindles with 18.000 rpm - Best damping and guiding properties of the milling spindles result in better workpiece quality and longer tool life - Outstanding dynamics thanks to high rapid traverse rates and acceleration values - Already included: The iXpanel - iX4.0 operating system with 18.5" touch screen based on Siemens S840D sl

Translated with DeepL

Loading ...