Kyocera SGS Showcases Z-Carb High Performance Rougher End Mill Expansion Range at EMO Hannover

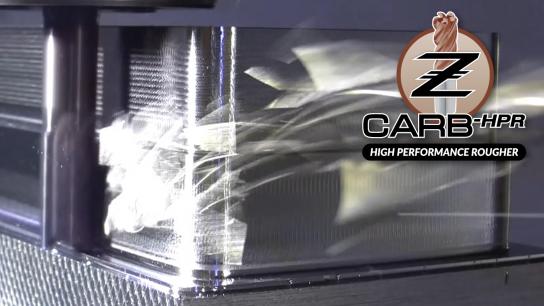

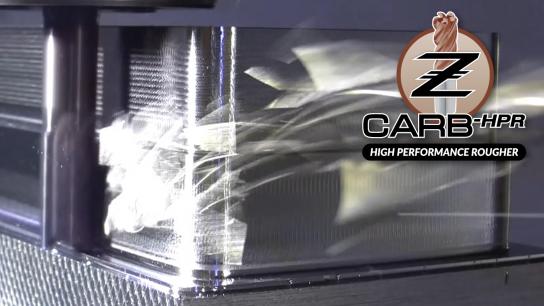

To meet customer demands, KYOCERA SGS Precision Tools Europe has expanded the popular Z-Carb HPR high-performance five-flute end mill line with over 900 new tools featuring new long, extended reach, and chip breaker options to combat a wider variety of high metal removal roughing operations.

Utilised extensively in the aerospace, automotive, and medical machining industries, SGS’s high performance Z-Carb HPR five-flute roughing end mills are perfect for achieving high material removal rates (MRR) and superior finishes. The specialized five-flute design is engineered to drastically increase productivity 20-40% over conventional three and four-flute end mills. It features variable indexing geometry, which improves chatter suppression over symmetrical designs. The Z-Carb HPR portfolio is equipped with various lengths, reach, square, and corner radius styles, along with new chip breaker options to address different machining situations. These end mills are coated with Ti-NAMITE®-M and Ti-NAMITE®-A, ensuring superior performance even in difficult-to-machine materials like Titanium and Stainless Steel.

We will be showcasing this new expansion range at our upcoming EMO Hannover 2023 exhibition stand, please visit our stand D69 in Hall 5 where you will be able to see our most productive tooling range.

Features & Benefits:

- NEW long, reach, and chip breaker options available!

- Over 1,700 items in range

- Full complement of corner radii available

- Central coolant hole and chip breaker options available on select diameters

- Plain and Weldon Flat options available for diameters ½” / 12mm and above (other retention methods available upon request)

- 6mm cutting diameters and above

- Special tooling design attributes available upon request

- Ti-NAMITE®-M coating for higher heat resistance to enhance tool life in Cast Iron, Steel and with difficult to machine materials like Titanium.

- Ti-NAMITE®-A coating for superior wear, edge build-up resistance and extended tool life in high temperature alloys and stainless steel applications.

Series Product Details:

- Cutting Diameter: 6,0mm - 25,0mm

- Length of Cut: 9,0mm - 75,0mm

- Overall Length: 54,0mm - 170,0mm

- Shank Diameter: 6,0mm - 25,0mm

- Corner Radius: 0,3mm - 5,0mm

- Coatings: Ti-NAMITE®-M, Ti-NAMITE®-A

- Special Options: Internal Coolant, Weldon Flat, Chip Breaker

Material Applications:

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- High-Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications:

- Aerospace

- Medical

- Power Generation

- Automotive

- Mold & Die

- General Engineering

To meet customer demands, KYOCERA SGS Precision Tools Europe has expanded the popular Z-Carb HPR high-performance five-flute end mill line with over 900 new tools featuring new long, extended reach, and chip breaker options to combat a wider variety of high metal removal roughing operations.

Utilised extensively in the aerospace, automotive, and medical machining industries, SGS’s high performance Z-Carb HPR five-flute roughing end mills are perfect for achieving high material removal rates (MRR) and superior finishes. The specialized five-flute design is engineered to drastically increase productivity 20-40% over conventional three and four-flute end mills. It features variable indexing geometry, which improves chatter suppression over symmetrical designs. The Z-Carb HPR portfolio is equipped with various lengths, reach, square, and corner radius styles, along with new chip breaker options to address different machining situations. These end mills are coated with Ti-NAMITE®-M and Ti-NAMITE®-A, ensuring superior performance even in difficult-to-machine materials like Titanium and Stainless Steel.

We will be showcasing this new expansion range at our upcoming EMO Hannover 2023 exhibition stand, please visit our stand D69 in Hall 5 where you will be able to see our most productive tooling range.

Features & Benefits:

- NEW long, reach, and chip breaker options available!

- Over 1,700 items in range

- Full complement of corner radii available

- Central coolant hole and chip breaker options available on select diameters

- Plain and Weldon Flat options available for diameters ½” / 12mm and above (other retention methods available upon request)

- 6mm cutting diameters and above

- Special tooling design attributes available upon request

- Ti-NAMITE®-M coating for higher heat resistance to enhance tool life in Cast Iron, Steel and with difficult to machine materials like Titanium.

- Ti-NAMITE®-A coating for superior wear, edge build-up resistance and extended tool life in high temperature alloys and stainless steel applications.

Series Product Details:

- Cutting Diameter: 6,0mm - 25,0mm

- Length of Cut: 9,0mm - 75,0mm

- Overall Length: 54,0mm - 170,0mm

- Shank Diameter: 6,0mm - 25,0mm

- Corner Radius: 0,3mm - 5,0mm

- Coatings: Ti-NAMITE®-M, Ti-NAMITE®-A

- Special Options: Internal Coolant, Weldon Flat, Chip Breaker

Material Applications:

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- High-Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications:

- Aerospace

- Medical

- Power Generation

- Automotive

- Mold & Die

- General Engineering