LACH DIAMANT

Products

Precision tools & clamping technology

Abrasive tools and products

Metal bon CBN Grinding Wheel Tuned to Maximum Perfomance a result of »contour-profiled« technology

|

Diamond grinding wheel, diamond paste

Lach Diamant Jakob Lach GmbH & Co. KG

Abrasive products with diamond

| 13,5 mm | |

| 0,5 mm | |

| 75% |

As is so often the case, great innovations remain behind closed doors because one does not even get the idea of questioning how many everyday objects are produced. Or have you ever broken your head about how a hair clipper is made?

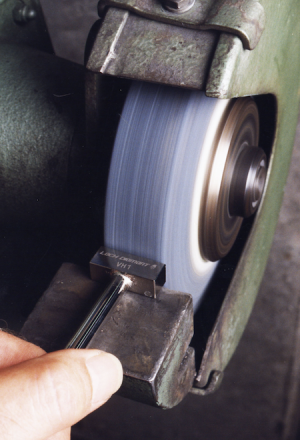

LACH DIAMANT has faced exactly this topic and again proved the unlimited possibilities of the "contour-profiled"; technology for profile grinding of metal bonded diamond and CBN grinding wheels. Even profile depths of 13. 5 mm with a web width of 0. 5 mm are produced by the Hanau pioneers without any problems and thus make it possible to simplify the production of a hair clipper.

Until now, hair trimmers had to be ground with conventional grinding wheels. The manufacturing process was highly complex as the conventional disc had to be dressed after each stroke to maintain the profile of a hair cutting blade.

The newly developed "contour-profiled"; grinding wheel from LACH DIAMANT consists of a metallic bond matrix which eliminates the need for re-profiling during the grinding process. The entire profile has already been applied to a "mini-contour-profiled"; machine using the "EDG-plus"; spark erosion process developed by LACH DIAMANT. For the user or manufacturer of the hair cutting blade, this means

Einzel-Abrichtdiamanten

|

Dressing tool

Handvielkorn-Abrichter

|

Dressing tool

Profil-Abrichtdiamanten

|

Dressing tool

Schleifen von Holz und Kunststoff-Bearbeitungswerkzeugen DragonFly

|

Abrasive product with diamond

Lach Diamant Jakob Lach GmbH & Co. KG

Abrasive products with diamond

Cutting tools

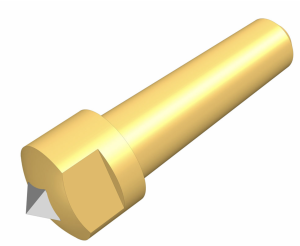

IC-Plus - The Titan of the Chipbreaker

|

PCD Insert with active Chipbreaker

Lach Diamant Jakob Lach GmbH & Co. KG

Inserts for turning

| from 0,1 mm | |

| aluminium-, magnesium-, copper-, bronze- alloy |

While CO-type chip breakers only redirect the chips, the new »IC-plus world`s best« chip breaker will already guide chips with a cutting depth (ap) of 0.01 mm. The cutting depth can be increased up to the maximum length of the cutting edge.

LACH DIAMANT can look back on twenty years of experience in the development of PCD chip breakers.

The first CO-type patent was issued on January 26, 1999: A laser cut chip groove for PCD materials.

Practice has shown, however, that chip breakers with a so manufactured chip groove have proven to be only suitable to a limited extent for a process-reliable, controlled chip breaking process of long chipping aluminium alloys.

An active chip breaker was the final solution. It had to show outstanding performance during rough machining as well as fine finishing.

LACH DIAMANT’s PCD »IC-plus« already announced as the »world`s best« chip breaker was born.

PCD monoblock milling cutters

|

Surface milling tool

Lach Diamant Jakob Lach GmbH & Co. KG

Surface milling tools

Monoblock Diamond Milling Cutter for face and square angle milling of all aluminium alloys

Another innovation of LACH-DIAMANT for the automotive and accessories industry ? for greater productivity and economic efficiency

? due to the compact precise design and resulting in a higher number of teeth

? extremely high cutting speeds (HSC) and feeds from 0.05 to 0.20 mm per tooth

? large depths of cut

? suitable for roughing ? finishing ? fine finishing

? no annoying cutting edge adjustments

? maximum tool life and cutting edge stability due to special PCD diamond qualities

? multiple life time of diamond cutting edges ? i.e. production capacity ? through the LACHDIAMANT regrinding service

Other special advantages of the »dia-compact« design:

? no storage of spare parts necessary, as is necessary for traditional insert systems

? integrated coolant supply

? wear-resistant flute for chips

? special dimensions and other types of cutting edges available upon request

In November 2004, when LACH DIAMANT was awarded the Hessian Innovation Prize for a newly developed technology for the cost and time efficient machining of aluminium components with a monoblock diamond cutter »dia-compact«, it was already said "Nothing is more efficient than this...".

However, there was still something more efficient ? as proven by the development of »Cool Injection-Plus», cooling directly via the PCD cutting insert.

Today, maximum tool life, extremely high cutting results and feed rates are taken for granted by leading automotive manufacturers and suppliers due to the use of LACH DIAMANT's monoblock milling cutters.

In addition, perfect surface quality and part accuracy have been achieved ? followed by reductions of cycle time by 50% and more.

The PCD monoblock milling cutter by LACH DIAMANT is completely mounted and balanced, delivered with an adapter of your choice and it can be immediately used on a machine, without adjustments.

CBN inserts DUO-Power

|

Insert for turning

Lach Diamant Jakob Lach GmbH & Co. KG

Inserts for turning

CBN inserts with »chipbreaker«* – another innovation of LACH DIAMANT

With the development of the »chipbreaker« for the turning of hardened steels and cast iron, entirely new possibilities were opened up. This began at LACH DIAMANT already 10 years ago and led to several patents. The question „turning or grinding?“ has now another option which goes in favour of CBN turning.

With this development LACH DIAMANT draws from 35 years of experience in the manufacturing and application of polycrystalline synthetic cutting materials diamond (PCD) and CBN (PCBn). This started with their availability of PCD in 1973 respectively 1974 for CBN.

LACH DIAMANT employs 150 people with plants in Hanau and Lichtenau near Chemnitz in Germany as well as in Grand Rapids, Michigan, USA and is considered a pioneer in this type of industry.

Even the grinding and spark erosion processing of polycrystalline materials had its origin in the „think tank“ of LACH DIAMANT, as proven by the universal grinding machines according to the original spark erosion process by LACH DIAMANT.