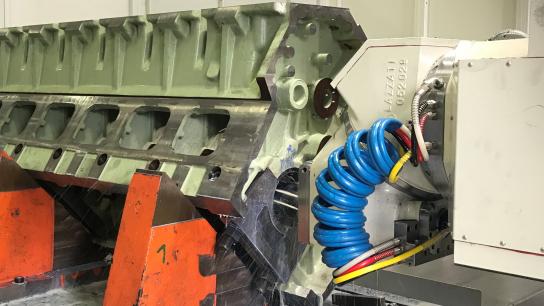

LAZZATI S.p.A. High Performance Boring Mills

LAZZATI Boring Mills: reduction of working times, rigidity, precision and high reliability

LAZZATI has a deep attention to #service and #maintenance.

Carrying out regular maintenance is always recommended because in this way, in addition to being sure of having a perfectly efficient and safe machine, it will be possible to extend its life and maintain its performance over time.

These interventions are necessary to maintain the original integrity of the machine, keep or restore its efficiency, contain normal wear and tear, guarantee its useful life and deal with accidental events.

In addition to the above, we would like to remind you to comply with the requirements relating to maintenance, control and above all the change of ropes; this is not only functional to the proper functioning of the machine and to the maintaining of its performance over time, but above all it is essential for the safety of the machine and of the operators.

Meet LAZZATI at EMO Hannover 2025

We’re proud to announce that LAZZATI will exhibit at EMO Hannover 2025, the world’s leading trade fair for manufacturing technologies.

September 22–26, 2025 – Hall 13, Stand C14

The event will focus on digitalization, automation, sustainability, and AI in metalworking. Special areas will also cover Additive Manufacturing and Industry 4.0 solutions.

With exhibitors from all over the world, EMO Hannover is the ideal venue to discover the latest in precision engineering and meet our technical team in person.

We look forward to welcoming you at our stand — come discover how LAZZATI Hydrostatic Technology can transform your production.

Contact us: [email protected]

More at: www.lazzati.eu

LAZZATI – The Hydrostatic Boring Mill

We Boost Your Profits

#EMOHannover2025 #Lazzati #BoringMills #CircularInterpolation #RoughMachining

#CNC #Metalworking #SmartManufacturing #Industry40 #HydrostaticTechnology #MadeInItaly#EMO2025 #MadeForMetalworking

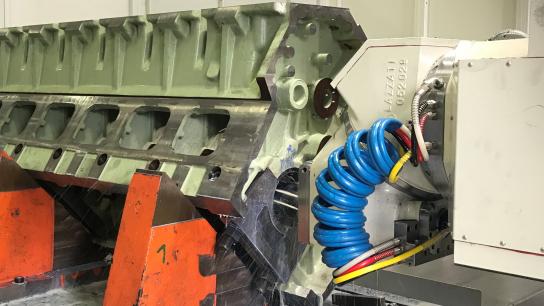

LAZZATI has a deep attention to #service and #maintenance.

Carrying out regular maintenance is always recommended because in this way, in addition to being sure of having a perfectly efficient and safe machine, it will be possible to extend its life and maintain its performance over time.

These interventions are necessary to maintain the original integrity of the machine, keep or restore its efficiency, contain normal wear and tear, guarantee its useful life and deal with accidental events.

In addition to the above, we would like to remind you to comply with the requirements relating to maintenance, control and above all the change of ropes; this is not only functional to the proper functioning of the machine and to the maintaining of its performance over time, but above all it is essential for the safety of the machine and of the operators.

Meet LAZZATI at EMO Hannover 2025

We’re proud to announce that LAZZATI will exhibit at EMO Hannover 2025, the world’s leading trade fair for manufacturing technologies.

September 22–26, 2025 – Hall 13, Stand C14

The event will focus on digitalization, automation, sustainability, and AI in metalworking. Special areas will also cover Additive Manufacturing and Industry 4.0 solutions.

With exhibitors from all over the world, EMO Hannover is the ideal venue to discover the latest in precision engineering and meet our technical team in person.

We look forward to welcoming you at our stand — come discover how LAZZATI Hydrostatic Technology can transform your production.

Contact us: [email protected]

More at: www.lazzati.eu

LAZZATI – The Hydrostatic Boring Mill

We Boost Your Profits

#EMOHannover2025 #Lazzati #BoringMills #CircularInterpolation #RoughMachining

#CNC #Metalworking #SmartManufacturing #Industry40 #HydrostaticTechnology #MadeInItaly#EMO2025 #MadeForMetalworking