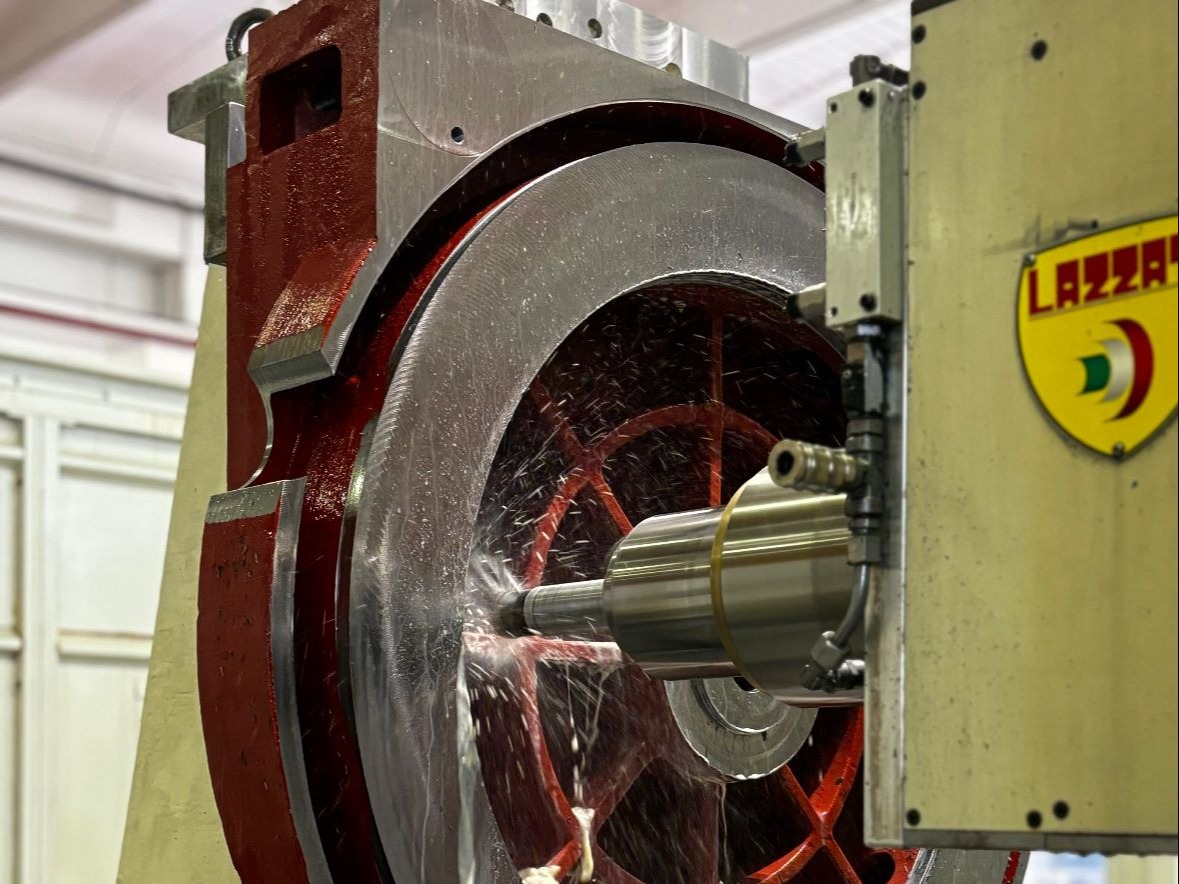

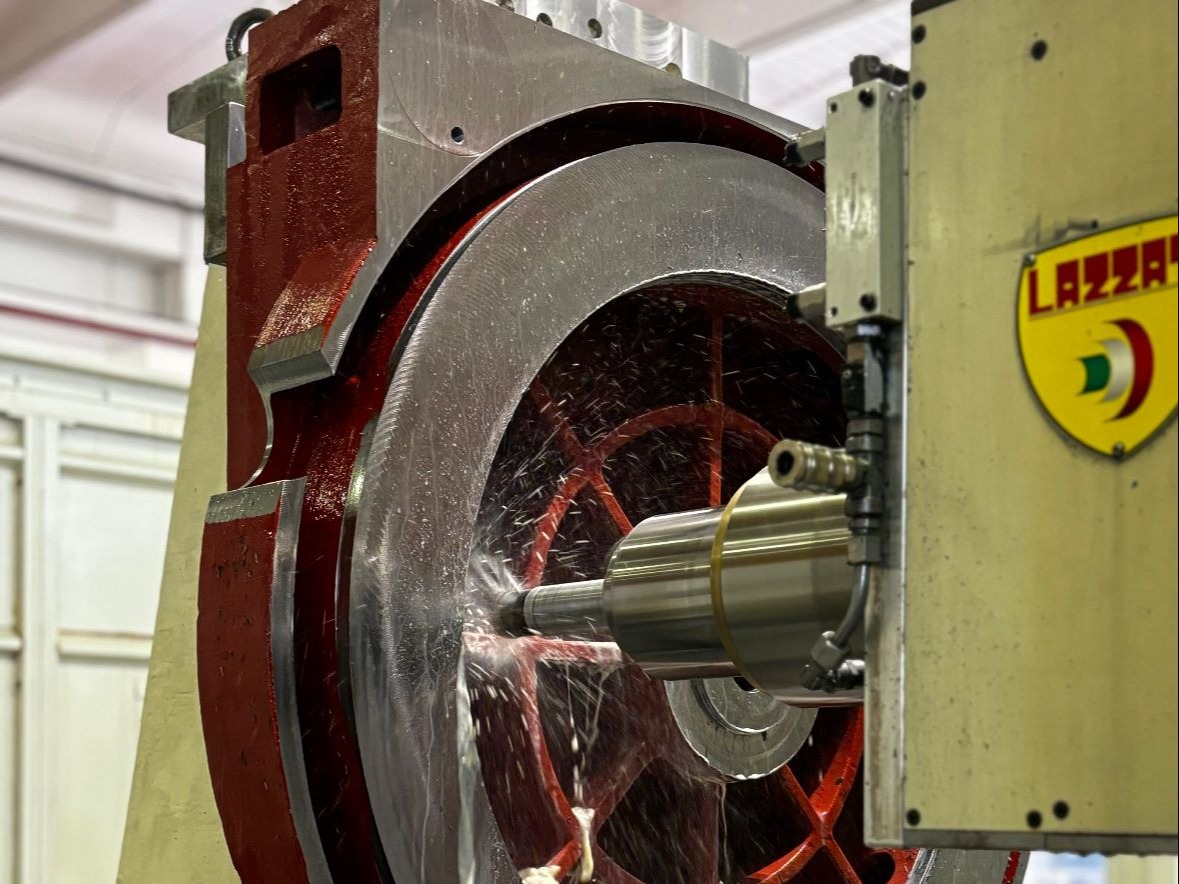

LAZZATI S.p.A. High Performance Boring Mills

LAZZATI SMART MAINTENANCE STRATEGY: Keep Your Boring Mills Always at its Highest Value!

LAZZATI SMART MAINTENANCE STRATEGY:

1. Smart Maintenance Optimization

LAZZATI machines are equipped with advanced features that streamline maintenance and reduce unnecessary interventions:

- Real Working Hours Count: Maintenance is based on spindle rotation time rather than mere machine uptime.

- Oil Quality Monitoring: Change oil only when it's truly needed.

- ALC – Automatic Level Check: The system alerts you only when geometry or leveling issues arise—eliminating needless recalibration.

- Onboard Maintenance Scheduling: Manage maintenance directly from the CNC.

- LHI 5.0 Interface: Access tutorials, manuals, and videos right at the control panel.

- LIA 1.0 – LAZZATI Intelligent Assistant: This AI-based system analyzes real-time machine performance to suggest optimal usage and maintenance strategies.

2. Machines Designed to Minimize Maintenance

LAZZATI machines are engineered with features that inherently reduce maintenance needs:

- Hydrostatic Axes: Reduced friction and vibration improve machining efficiency and prolong tool life.

- Spindle Lubrication for Life: Designed for minimal scheduled maintenance.

- Thermal Control System (TCS): Stabilizes temperature to ensure consistent boring performance.

- Universal Heads with Dry-Case Hydraulic Lubrication: Built in-house to eliminate routine maintenance requirements.

3. Reducing Operator-Induced Damage

Our proactive safety features help protect your investment:

- Hydrostatic Systems: Prevent accidental collisions that could damage guideways.

- Digital 3D Machine Model: Available for offline simulation and crash prediction.

- OCM – LAZZATI Collision Monitoring: Detects and reacts to abnormal forces in milliseconds.

- Anti-slip Transmission System: Safeguards drive components.

- LFC – LAZZATI Feed Control: Actively manages forces during machining to reduce tool wear and enhance surface quality.

4. Predictable Maintenance, Controlled Costs

LAZZATI offers predictable, cost-effective maintenance services through scheduled checks:

- LO&M 1000 – Scheduled Check Every 1000 Hours of Spindle Rotation

What’s Included:

- Verification of spindle rotation parameters and axis loads

- Comprehensive mechanical inspection

- Wear parts check and replacement

- Dynamic performance testing and data comparison with commissioning values

- Safety system checks

- LO&M 2000 – Scheduled Check Every 2000 Hours of Spindle Rotation

What’s Included:

- In-depth verification of spindle and axis parameters

- Extensive mechanical and accessory inspections

- Wear parts replacement and adjustment of key components

- Full hydrostatic system inspection and oil quality assessment

- Dynamic performance testing along with safety checks

Note: All operations are performed by highly qualified LAZZATI technicians using official checklists and calibrated instruments.

Customer Benefits

- Consistent production efficiency

- Extended machine lifetime

- Reduced extraordinary maintenance costs

- Flexible scheduling tailored to your production needs

- Personalized technical support with real-time updates

- Complimentary Teleservice support with scheduled contracts

- A productive machine is a profitable machine.

- Maintaining your LAZZATI means preserving the value of your productivity.

- Stay ahead by preventing issues before they arise.

Meet LAZZATI at EMO Hannover 2025

We’re proud to announce that LAZZATI will exhibit at EMO Hannover 2025, the world’s leading trade fair for manufacturing technologies.

September 22–26, 2025 – Hall 13, Stand C14

The event will focus on digitalization, automation, sustainability, and AI in metalworking. Special areas will also cover Additive Manufacturing and Industry 4.0 solutions.

With exhibitors from all over the world, EMO Hannover is the ideal venue to discover the latest in precision engineering and meet our technical team in person.

We look forward to welcoming you at our stand — come discover how LAZZATI Hydrostatic Technology can transform your production.

Contact us: [email protected]

More at: www.lazzati.eu

LAZZATI – The Hydrostatic Boring Mill

We Boost Your Profits

#EMOHannover2025 #Lazzati #BoringMills #CircularInterpolation #RoughMachining

#CNC #Metalworking #SmartManufacturing #Industry40 #HydrostaticTechnology #MadeInItaly#EMO2025 #MadeForMetalworking

LAZZATI SMART MAINTENANCE STRATEGY:

1. Smart Maintenance Optimization

LAZZATI machines are equipped with advanced features that streamline maintenance and reduce unnecessary interventions:

- Real Working Hours Count: Maintenance is based on spindle rotation time rather than mere machine uptime.

- Oil Quality Monitoring: Change oil only when it's truly needed.

- ALC – Automatic Level Check: The system alerts you only when geometry or leveling issues arise—eliminating needless recalibration.

- Onboard Maintenance Scheduling: Manage maintenance directly from the CNC.

- LHI 5.0 Interface: Access tutorials, manuals, and videos right at the control panel.

- LIA 1.0 – LAZZATI Intelligent Assistant: This AI-based system analyzes real-time machine performance to suggest optimal usage and maintenance strategies.

2. Machines Designed to Minimize Maintenance

LAZZATI machines are engineered with features that inherently reduce maintenance needs:

- Hydrostatic Axes: Reduced friction and vibration improve machining efficiency and prolong tool life.

- Spindle Lubrication for Life: Designed for minimal scheduled maintenance.

- Thermal Control System (TCS): Stabilizes temperature to ensure consistent boring performance.

- Universal Heads with Dry-Case Hydraulic Lubrication: Built in-house to eliminate routine maintenance requirements.

3. Reducing Operator-Induced Damage

Our proactive safety features help protect your investment:

- Hydrostatic Systems: Prevent accidental collisions that could damage guideways.

- Digital 3D Machine Model: Available for offline simulation and crash prediction.

- OCM – LAZZATI Collision Monitoring: Detects and reacts to abnormal forces in milliseconds.

- Anti-slip Transmission System: Safeguards drive components.

- LFC – LAZZATI Feed Control: Actively manages forces during machining to reduce tool wear and enhance surface quality.

4. Predictable Maintenance, Controlled Costs

LAZZATI offers predictable, cost-effective maintenance services through scheduled checks:

- LO&M 1000 – Scheduled Check Every 1000 Hours of Spindle Rotation

What’s Included:

- Verification of spindle rotation parameters and axis loads

- Comprehensive mechanical inspection

- Wear parts check and replacement

- Dynamic performance testing and data comparison with commissioning values

- Safety system checks

- LO&M 2000 – Scheduled Check Every 2000 Hours of Spindle Rotation

What’s Included:

- In-depth verification of spindle and axis parameters

- Extensive mechanical and accessory inspections

- Wear parts replacement and adjustment of key components

- Full hydrostatic system inspection and oil quality assessment

- Dynamic performance testing along with safety checks

Note: All operations are performed by highly qualified LAZZATI technicians using official checklists and calibrated instruments.

Customer Benefits

- Consistent production efficiency

- Extended machine lifetime

- Reduced extraordinary maintenance costs

- Flexible scheduling tailored to your production needs

- Personalized technical support with real-time updates

- Complimentary Teleservice support with scheduled contracts

- A productive machine is a profitable machine.

- Maintaining your LAZZATI means preserving the value of your productivity.

- Stay ahead by preventing issues before they arise.

Meet LAZZATI at EMO Hannover 2025

We’re proud to announce that LAZZATI will exhibit at EMO Hannover 2025, the world’s leading trade fair for manufacturing technologies.

September 22–26, 2025 – Hall 13, Stand C14

The event will focus on digitalization, automation, sustainability, and AI in metalworking. Special areas will also cover Additive Manufacturing and Industry 4.0 solutions.

With exhibitors from all over the world, EMO Hannover is the ideal venue to discover the latest in precision engineering and meet our technical team in person.

We look forward to welcoming you at our stand — come discover how LAZZATI Hydrostatic Technology can transform your production.

Contact us: [email protected]

More at: www.lazzati.eu

LAZZATI – The Hydrostatic Boring Mill

We Boost Your Profits

#EMOHannover2025 #Lazzati #BoringMills #CircularInterpolation #RoughMachining

#CNC #Metalworking #SmartManufacturing #Industry40 #HydrostaticTechnology #MadeInItaly#EMO2025 #MadeForMetalworking