Levicron

Products

Mechanical components

High speed spindles

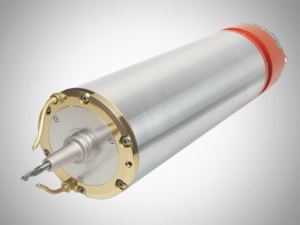

"ASD-H20A/ UASD-H20A"

|

High speed spindle

Levicron GmbH

High speed spindles

About the "ASD-H20A/ UASD-H20A

with axial (A) oriented spindle connections

By using our springless, patented HSK clamping system SLH-x in size HSK-20, a consistent optimization of the shaft dynamics and the highly efficient and symmetrical thin-film liquid cooling, our ASD-H20A, to the previous solutions, also offers an unrivaled dynamic or thermal stability. In addition to this stability, our customers can simultaneously expect highly dynamic machining of small and integral components. This is because of our manufacturing expertise, which we use for our ultra-precise spindle models, and our patented bearing technology.

with axial (A) oriented spindle connections

- Highest speeds up to 150,000 rpm for fully automtaed machining of small and integral compontens.

- Developed primarily for the production of integral semiconductor components and optoelectronics components

- Also available with a high-pressure aerostatic bearing system (HASD-H20A)

- Features an automatic and springless HSK-E20 tool interface

By using our springless, patented HSK clamping system SLH-x in size HSK-20, a consistent optimization of the shaft dynamics and the highly efficient and symmetrical thin-film liquid cooling, our ASD-H20A, to the previous solutions, also offers an unrivaled dynamic or thermal stability. In addition to this stability, our customers can simultaneously expect highly dynamic machining of small and integral components. This is because of our manufacturing expertise, which we use for our ultra-precise spindle models, and our patented bearing technology.

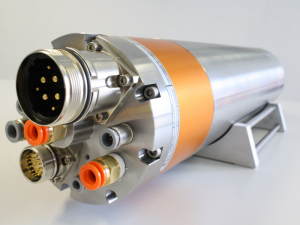

"ASD-H25(A)/ UASD-H25(A)"

|

High speed spindle

Levicron GmbH

High speed spindles

About the "ASD-H25(A)/ UASD-H25(A)"

with radial or axial (A) oriented spindle connections

As a result, users in CNC machining get unprecedented precision, thermal stability, and the ability to machine optical surfaces in milling and grinding applications. In contrast, in ultra-precision machining, the user gets high chip removal and automated tool change for a significant increase in productivity and automation.

with radial or axial (A) oriented spindle connections

- High speeds for micromachining up to 90,000 rpm

- Low Error Motion values for machining optical components

- Also available with a high-pressure aerostatic bearing system (UASD-H25)

- Features an automatic and springless HSK-E25 tool interface

As a result, users in CNC machining get unprecedented precision, thermal stability, and the ability to machine optical surfaces in milling and grinding applications. In contrast, in ultra-precision machining, the user gets high chip removal and automated tool change for a significant increase in productivity and automation.

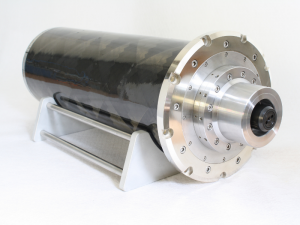

"UASD-H40A"

|

High speed spindle

Levicron GmbH

High speed spindles

About the "UASD-H40A"

with axial (A) orientied spindle connections

Compared to hydrostatic tool spindles, our UASD-H40A offers the following advantages:

Equal load capacities and significant cost savings in energy requirements (despite 50% higher maximum speeds) for peripherals and service. In addition, the spindle records an extremely compact and maintenance-friendly design due to the much simpler sealing technology.

with axial (A) orientied spindle connections

- A radial/ axial load capacity on the tool of up to 400 kg

- The first full-range tool spindle for roughing and high-speed machining

- Roughing with a 10 mm tool in steel and a speed of up to 60,000 rpm

- Features an automatic and springless HSK-E40 tool interfaces

Compared to hydrostatic tool spindles, our UASD-H40A offers the following advantages:

Equal load capacities and significant cost savings in energy requirements (despite 50% higher maximum speeds) for peripherals and service. In addition, the spindle records an extremely compact and maintenance-friendly design due to the much simpler sealing technology.

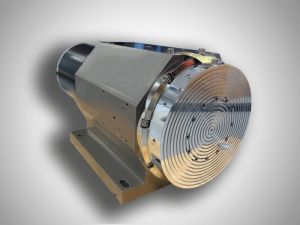

Main spindles for turning, milling, boring, boring and milling machines

Aerostatic CNC Tool spindle "ASD-PH63M"

|

Main spindle for turning, milling, boring, boring and milling machines

Levicron GmbH

Main spindles for turning, milling, boring, boring and milling machines

About the "ASD-PH63M"

As a result, the user in ultra-precision and CNC machining gets a thermally stable solution for generating optical components or for high-precision positioning in axis mode.

Our spindle is also available as a workpiece spindle (ASD-Px).

- Ultraprecise accuracies & Rotational scatter better than 15 nm (Error-Motion)

- The highest spindle stiffnesses and load capacities for aerostatic work spindles on the market

- A constant torque of 13 Nm and a speed up to 12,000 rpm

- Possesses a manual HSK-A63 tool clamping system

As a result, the user in ultra-precision and CNC machining gets a thermally stable solution for generating optical components or for high-precision positioning in axis mode.

Our spindle is also available as a workpiece spindle (ASD-Px).

Workpiece spindle "ASD-Px"

|

Main spindle for turning, milling, boring, boring and milling machines

Levicron GmbH

Main spindles for turning, milling, boring, boring and milling machines

About "ASD-Px"

As a result, the user in ultra-precision machining gets a spindle solution for all concerns of workpiece rotation. These include, on the one hand, the machining of particularly large workpieces at low speeds, particularly small workpieces at high speeds, and, last but not least, precise orientation in axis mode.

About the workpiece clamping

The chuck interface consists of a ground faceplate with a diameter of 120 mm and a standardized hole circle pattern. Own or commercially available rotary workpiece clamping devices can be attached to this.

Our spindle is also available as a tool motor spindle to accommodate large grinding wheels (ASD-PH63M).

- Workpiece motor spindle for turning, fly cutting & positioning

- It can function as a turning spindle (with variable workpiece clamping) or be used for accurate workpiece angle positioning

- Speeds up to 12,000 rpm while maintaining the highest rigidity on the market

- Stable machining (rotational fidelity or error motion < 15 nm) of large, heavy components & small lenses

As a result, the user in ultra-precision machining gets a spindle solution for all concerns of workpiece rotation. These include, on the one hand, the machining of particularly large workpieces at low speeds, particularly small workpieces at high speeds, and, last but not least, precise orientation in axis mode.

About the workpiece clamping

The chuck interface consists of a ground faceplate with a diameter of 120 mm and a standardized hole circle pattern. Own or commercially available rotary workpiece clamping devices can be attached to this.

Our spindle is also available as a tool motor spindle to accommodate large grinding wheels (ASD-PH63M).