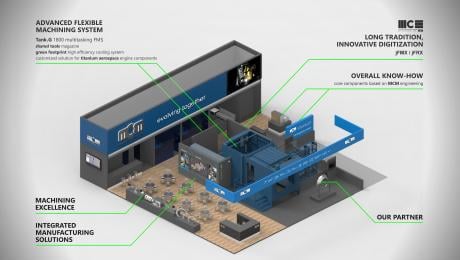

Integrated Manufacturing Solutions

#EMO 2019 - MCM Booth - Hall 13 C14 #evolving together

The MCM integrated offer on display at EMO Hannover 2019 _ HALL 13 C14

Under the Spotlights:

TANK.G 1800 Multitasking (Milling-Turning-Grinding) Machining Center

- Integration, on the machining centre, of the grinding functions and of all the equipment and devices necessary to carry out and optimise this process. Complete and automatic management of the abrasive tools for the grinding process.

- Management of different types of angular return heads. Possibility of direct tool change on the heads and storage in the tool magazines.

- Innovative customised cooling system based on mains water supply available at the place of installation. Thanks to an efficient air-water heat exchanger system allowing the cooling of all heat-sensitive components such as the spindle, rotary table, the tilting system, electrical cabinets and the coolant fluid tank.

- The machine represents an example of flexible automation and system modularity. It is the third step of one of the FMS installed at MTU (case history here attached) and all is managed by the exclusive ‘jFMX’ supervision software, developed by MCE.

KEY COMPONENT: Tilting Head TANK / TANK.G

- MCM exhibits a tilting head driven by two high-performance torque motors, housing a spindle for roughing operations on difficult-to-machine materials offering around 1300 Nm and 6000 RPM.

- Both the head and the spindle are designed and assembled by MCM. They are examples of how MCM has complete control of its products, facilitating customisation, flexibility, the possibility of reconfiguration and maintenance.

Innovation and Applied Research: jFRX

- Flight Recorder is an innovative tool associated with the jFMX supervision software that enables the predictive maintenance. A special industrial PC installed on board the machine collects real-time data coming from the machine sensors, thus is able to trace, analyse and correlate all the process information, from the single machine signals to the performance indexes of an entire line. It is possible to forecast possible production degradations and increase the service provision.

- MCM is one of the most active and virtuous companies from the point of view of applied industrial research, it boasts numerous collaborations with universities and research institutes.

MCE CORNER

- MCE (the information technologies division of MCM) was founded in 1986, since then develops software services for production management, organized in the 'jFMX' suites. The jFMX architecture is structured on different levels in order to manage the growing complexity of systems and information, up to a possible coordination and centralized management of an entire workshop.

MACHINED PARTS

MCM is a reliable partner for companies of all sizes belonging to all sectors of precision mechanics, in particular aerospace, transport, industry, energy. Each sector will be represented by the exposed components, processed by customers on MCM machining centres and FMS and for which, when requested, a complete process study was performed by MCM.

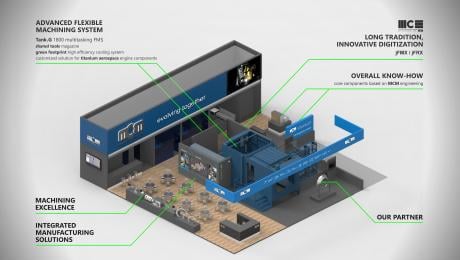

The MCM integrated offer on display at EMO Hannover 2019 _ HALL 13 C14

Under the Spotlights:

TANK.G 1800 Multitasking (Milling-Turning-Grinding) Machining Center

- Integration, on the machining centre, of the grinding functions and of all the equipment and devices necessary to carry out and optimise this process. Complete and automatic management of the abrasive tools for the grinding process.

- Management of different types of angular return heads. Possibility of direct tool change on the heads and storage in the tool magazines.

- Innovative customised cooling system based on mains water supply available at the place of installation. Thanks to an efficient air-water heat exchanger system allowing the cooling of all heat-sensitive components such as the spindle, rotary table, the tilting system, electrical cabinets and the coolant fluid tank.

- The machine represents an example of flexible automation and system modularity. It is the third step of one of the FMS installed at MTU (case history here attached) and all is managed by the exclusive ‘jFMX’ supervision software, developed by MCE.

KEY COMPONENT: Tilting Head TANK / TANK.G

- MCM exhibits a tilting head driven by two high-performance torque motors, housing a spindle for roughing operations on difficult-to-machine materials offering around 1300 Nm and 6000 RPM.

- Both the head and the spindle are designed and assembled by MCM. They are examples of how MCM has complete control of its products, facilitating customisation, flexibility, the possibility of reconfiguration and maintenance.

Innovation and Applied Research: jFRX

- Flight Recorder is an innovative tool associated with the jFMX supervision software that enables the predictive maintenance. A special industrial PC installed on board the machine collects real-time data coming from the machine sensors, thus is able to trace, analyse and correlate all the process information, from the single machine signals to the performance indexes of an entire line. It is possible to forecast possible production degradations and increase the service provision.

- MCM is one of the most active and virtuous companies from the point of view of applied industrial research, it boasts numerous collaborations with universities and research institutes.

MCE CORNER

- MCE (the information technologies division of MCM) was founded in 1986, since then develops software services for production management, organized in the 'jFMX' suites. The jFMX architecture is structured on different levels in order to manage the growing complexity of systems and information, up to a possible coordination and centralized management of an entire workshop.

MACHINED PARTS

MCM is a reliable partner for companies of all sizes belonging to all sectors of precision mechanics, in particular aerospace, transport, industry, energy. Each sector will be represented by the exposed components, processed by customers on MCM machining centres and FMS and for which, when requested, a complete process study was performed by MCM.