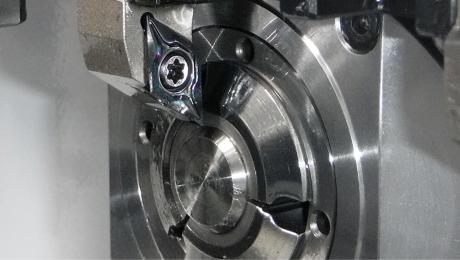

New insert grade MS7025 for turning stainless steel small parts

To improve performance when conducting small part machining, Mitsubishi Materials has now introduced a new insert grade to its range of precision turning inserts. Ideal for sliding head turning centres and intricate machining, the new MS7025 grade is the insert of choice for machining stainless steels.

The Nano multi-layer coating combines the high lubrication layer that provides excellent welding resistance, with a high hardness layer that suppresses the progress of wear. The damage usually caused by contact with the workpiece is also significantly reduced and increases tool life. The high lubrication layer suppresses built-up edge caused by chip welding which tends to occur in low feed and cutting speed machining. This has the benefit of reducing blemishes on the machined component surface.

A comparison test between MS7025 and a conventional grade was carried out to compare dimensional changes during low feed and cutting speed machining of stainless steel components (SUS440C, DIN1.4125). The results showed a large improvement in dimensional accuracy after machining many components, thereby reducing the number of insert changes. Another important benefit found throughout the test was that a consistently high quality surface finish could be maintained.

Mitsubishi Materials has also developed the new MS7025 grade with a minus corner radius tolerance to ensure precision corner geometry on workpieces. The minus tolerance is available with designations 02M and 04M that have a precision minus corner radii between R0.15 - R0.20 and R0.35 - R 0.40 mm respectively. The series has been launched with two chipbreakers, the FS-P chipbreaker which has been specified for micro through to low depths of cut and the LS-P for medium to high depth of cut applications. These chip breakers feature geometries ideal for each type as well as both having a mirror finish polished surface for efficient chip evacuation. Both types have extremely high quality cutting edges that maintain dimensional accuracy and also importantly, they drastically reduce burrs thereby negating the need for a further de-burring operation.

MS7025 grade is available in 7º positive geometries CCGT, DCGT and VCGT types. A wide range of stainless steels, ranging from austenitic, ferritic, electromagnetic through to precipitation hardening types can be successfully machined.

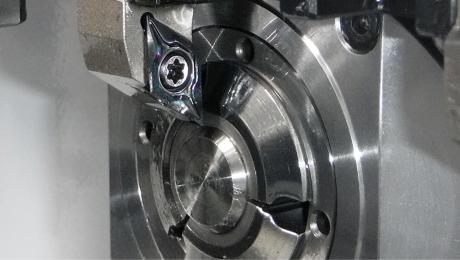

To improve performance when conducting small part machining, Mitsubishi Materials has now introduced a new insert grade to its range of precision turning inserts. Ideal for sliding head turning centres and intricate machining, the new MS7025 grade is the insert of choice for machining stainless steels.

The Nano multi-layer coating combines the high lubrication layer that provides excellent welding resistance, with a high hardness layer that suppresses the progress of wear. The damage usually caused by contact with the workpiece is also significantly reduced and increases tool life. The high lubrication layer suppresses built-up edge caused by chip welding which tends to occur in low feed and cutting speed machining. This has the benefit of reducing blemishes on the machined component surface.

A comparison test between MS7025 and a conventional grade was carried out to compare dimensional changes during low feed and cutting speed machining of stainless steel components (SUS440C, DIN1.4125). The results showed a large improvement in dimensional accuracy after machining many components, thereby reducing the number of insert changes. Another important benefit found throughout the test was that a consistently high quality surface finish could be maintained.

Mitsubishi Materials has also developed the new MS7025 grade with a minus corner radius tolerance to ensure precision corner geometry on workpieces. The minus tolerance is available with designations 02M and 04M that have a precision minus corner radii between R0.15 - R0.20 and R0.35 - R 0.40 mm respectively. The series has been launched with two chipbreakers, the FS-P chipbreaker which has been specified for micro through to low depths of cut and the LS-P for medium to high depth of cut applications. These chip breakers feature geometries ideal for each type as well as both having a mirror finish polished surface for efficient chip evacuation. Both types have extremely high quality cutting edges that maintain dimensional accuracy and also importantly, they drastically reduce burrs thereby negating the need for a further de-burring operation.

MS7025 grade is available in 7º positive geometries CCGT, DCGT and VCGT types. A wide range of stainless steels, ranging from austenitic, ferritic, electromagnetic through to precipitation hardening types can be successfully machined.