Nine9 MCC thread mill

Let’s Talk About Coil Thread Insert and How Nine9 MCC thread mill Could Help?

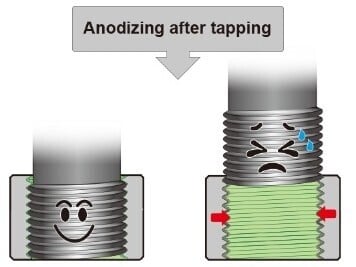

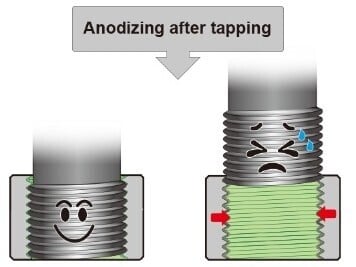

When installing a coil thread insert, used to repair or reinforce threaded holes, no matter the size, you need to create a pre-threaded hole using a specific tap designed for that insert. However, when the component undergoes surface coating treatments like anodizing after tapping, the pitch diameter of the thread often becomes smaller, leading to common problems with traditional methods:

Difficult Insertion: The coil thread insert may become hard to insert into the hole. After surface treatment, the hole can become too small for the screw, causing fitting issues.

Also due to the pitch diameter of the thread is fixed. This means there’s no flexibility to compensate for surface treatments like anodizing, leading to possible shrinkage and insertion problems.

Time-Consuming Process: Tapping involves multiple steps—preparation, cleaning, and lubricating each hole with tapping lubricant before tapping. All these steps are adding to production time.

Multiple Tools Required: Different taps are needed for each thread size, increasing costs and complicating tool inventory management.

How Nine9 Nine9 MCC thread mill could help?

With Nine9 MCC thread mill, you can overcome these problems and enjoy the following advantages:

Adjustable Pitch Diameter!

The thread milling program allows you to adjust the pitch diameter, eliminating the problem of thread shrinkage after surface treatments. Your insert thread dimensions will always fit perfectly, no matter the coating applied.

Versatility with One Tool!

One thread milling tool covers multiple thread sizes, eliminating the need for multiple taps. This simplifies tool management, saves time, and reduces costs.

No more fitting issues!

Enjoy smoother, more efficient thread creation with Nine9’s MCC Thread Mill!

Join us at EMO in Hall 5, Booth A13, to discover the latest innovations in high-performance indexable cutting tools!

Let’s Talk About Coil Thread Insert and How Nine9 MCC thread mill Could Help?

When installing a coil thread insert, used to repair or reinforce threaded holes, no matter the size, you need to create a pre-threaded hole using a specific tap designed for that insert. However, when the component undergoes surface coating treatments like anodizing after tapping, the pitch diameter of the thread often becomes smaller, leading to common problems with traditional methods:

Difficult Insertion: The coil thread insert may become hard to insert into the hole. After surface treatment, the hole can become too small for the screw, causing fitting issues.

Also due to the pitch diameter of the thread is fixed. This means there’s no flexibility to compensate for surface treatments like anodizing, leading to possible shrinkage and insertion problems.

Time-Consuming Process: Tapping involves multiple steps—preparation, cleaning, and lubricating each hole with tapping lubricant before tapping. All these steps are adding to production time.

Multiple Tools Required: Different taps are needed for each thread size, increasing costs and complicating tool inventory management.

How Nine9 Nine9 MCC thread mill could help?

With Nine9 MCC thread mill, you can overcome these problems and enjoy the following advantages:

Adjustable Pitch Diameter!

The thread milling program allows you to adjust the pitch diameter, eliminating the problem of thread shrinkage after surface treatments. Your insert thread dimensions will always fit perfectly, no matter the coating applied.

Versatility with One Tool!

One thread milling tool covers multiple thread sizes, eliminating the need for multiple taps. This simplifies tool management, saves time, and reduces costs.

No more fitting issues!

Enjoy smoother, more efficient thread creation with Nine9’s MCC Thread Mill!

Join us at EMO in Hall 5, Booth A13, to discover the latest innovations in high-performance indexable cutting tools!