Okuma Europe GmbH

Products

Machining centres

Horizontal machining centres

MA-500HII

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 500 x 500 | |

| 700/900/780 | |

| 6.000 [12.000, 15.000, 20.000] | |

| 40 [60,81,111,141,171,195,225,255,285,320,400] | |

| 30/22 [37/26] | |

| 60/60/60 | |

| 3.110 × 5.971 |

When your business calls for a machine that delivers high productivity without compromising on accuracy, look to the MA-H-II Series of horizontal machining centers. The fourth generation of a proven design platform, the MA-H-500H-II/600H-II machines boast a series of engineering features guaranteed to achieve results.

A high-speed axis feed of 60 m/min provides near instant access to parts, improving productivity. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s double sleeve spindle cooling system balances the spindle head temperature to prevent deformation and the resulting imperfection. The MA-H-II Series is the place to turn for the fast creation of precision-crafted components, a true advance in profitability.

MB-5000HII

|

Horizontal machining centre

Okuma Europe GmbH

Horizontal machining centres

| 500 x 500 | |

| X: 760 / Y: 760 / Z: 810 | |

| 15,000, 12,000, 20,000 | |

| 48, 64, 100, 140, 220, 260, 300, 340 | |

| 26/18.5, 33/26, 30/22 | |

| X: 60 / Y: 60 / Z: 60 | |

| 2,540 x 5,620 |

The MB-5000HII is a high-speed, thermally stable horizontal machining centre that offers quick acceleration, short tool changes, and high power to improve productivity. Compared to the previous model, this machine's powerful cutting capabilities and high-speed automation increase productivity and reduce cycle time by 25 percent, while the 20 percent smaller footprint maximises valuable shop floor space.

MA-600HII

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 630 × 630 | |

| 1.000/900/1.000 | |

| 6.000 [12.000, 15.000, 20.000] | |

| 40 [60,81,111,141,171,195,225,255,285,320,400] | |

| 30/22 [45/37, 37/26, 26/18.5, 30/22] | |

| 60/60/60 | |

| 3.410 × 6.495 |

When your business calls for a machine that delivers high productivity without compromising on accuracy, look to the MA-H-II Series of horizontal machining centers. The fourth generation of a proven design platform, the MA-H-500H-II/600H-II machines boast a series of engineering features guaranteed to achieve results.

A high-speed axis feed of 60 m/min provides near instant access to parts, improving productivity. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s double sleeve spindle cooling system balances the spindle head temperature to prevent deformation and the resulting imperfection. The MA-H-II Series is the place to turn for the fast creation of precision-crafted components, a true advance in profitability.

MA-400HA

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 400 x 400 | |

| 560/ 610/ 625 | |

| 8.000 [15.000, 20.000, 25.000, 35.000] | |

| 30 [40, 60, 100, 152, 198, 240] | |

| 15/11 [26/18.5, 30/22] | |

| 60/60/60 | |

| 2.394 x 4.532 |

When your business calls for a machine that delivers high productivity without compromising on accuracy, look to the MA-H Series of horizontal machining centers. This proven design platform boasts a series of engineering features guaranteed to achieve results. A high-speed axis feed of 60 m/min provides near instant access to parts, improving productivity and nearly eliminating the need to hold inventory. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s double sleeve spindle cooling system balances the spindle head temperature to prevent deformation and ensuring continuous, consistent accuracy. The MA-H Series is the place to turn for the fast creation of precision-crafted components, a true advance in profitability.

MA-800HB

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 800 x 800 | |

| 1.400/1.250/1.250 | |

| 6.000 [12.000] | |

| 40 [60,100,150,200,240,320,400] | |

| 30/22 [37/26] | |

| 50/50/50 | |

| 4.745 x 6.465 |

When your business calls for a machine that delivers high productivity without compromising on accuracy, look to the MA-H Series of horizontal machining centers. This proven design platform boasts a series of engineering features guaranteed to achieve results. A high-speed axis feed of 60 m/min provides near instant access to parts, improving productivity and nearly eliminating the need to hold inventory. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s double sleeve spindle cooling system balances the spindle head temperature to prevent deformation and ensuring continuous, consistent accuracy. The MA-H Series is the place to turn for the fast creation of precision-crafted components, a true advance in profitability.

MA-12500H

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 1.250 x 1.250 | |

| 2.200/1.600/1.650 | |

| 6.000 [4.500, 12.000] | |

| 81 [129, 177] | |

| 45/37 (40/37/30, 37/26) | |

| 42/42/42 | |

| 6.880 × 11.532 |

When your business calls for a machine that delivers high productivity without compromising on accuracy, look to the MA-H Series of horizontal machining centers. This proven design platform boasts a series of engineering features guaranteed to achieve results. A high-speed axis feed of 60 m/min provides near instant access to parts, improving productivity and nearly eliminating the need to hold inventory. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s double sleeve spindle cooling system balances the spindle head temperature to prevent deformation and ensuring continuous, consistent accuracy. The MA-H Series is the place to turn for the fast creation of precision-crafted components, a true advance in profitability.

MB-4000H

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 400 x 400 | |

| 560/560/625 | |

| 15.000 [20.000] | |

| 48 [64,110,146,182,218] | |

| 26/18,5 [30/22] | |

| 60/60/60 | |

| 2.420 × 4.700 |

The MB-H series provides a unique combination of high-speed and power in a small footprint. Highly productive with a high speed spindle and reduced non-cutting time, the MB-H series is built on the Okuma Thermo-Friendly Concept which enables the machine to predict and counter thermal deformation, ensuring consistent accuracy.

Each machine is expandable with modular ATC magazine and APC.

MB-5000H

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 500 × 500 | |

| 760/760/760 | |

| 15.000 [20.000] | |

| 48 [64,110,146,182,218] | |

| 26/18,5 [30/22] | |

| 60/60/60 | |

| 2.695 × 4.725 |

The MB-H series provides a unique combination of high-speed and power in a small footprint. Highly productive with a high speed spindle and reduced non-cutting time, the MB-H series is built on the Okuma Thermo-Friendly Concept which enables the machine to predict and counter thermal deformation, ensuring consistent accuracy.

Each machine is expandable with modular ATC magazine and APC.

MB-8000H

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 800 × 800 | |

| 1.300/1.100/1.250 | |

| 6.000 [12.000] | |

| 40 [60,81,111,141,171,195,225,255,285,320,400] | |

| 30/22 [37/26, 45/37] | |

| 50/50/50 | |

| 3.960 × 7.505 |

The MB-H series provides a unique combination of high-speed and power in a small footprint. Highly productive with a high speed spindle and reduced non-cutting time, the MB-H series is built on the Okuma Thermo-Friendly Concept which enables the machine to predict and counter thermal deformation, ensuring consistent accuracy.

Each machine is expandable with modular ATC magazine and APC.

MB-10000H

|

Horizontal Machining Centers

Okuma Europe GmbH

Horizontal machining centres

| 1.000 x 1.000 | |

| 1.400/1.250/1.250 | |

| 6.000 [12.000] | |

| 40 [60,100,150,200,240,320,400] | |

| 30/22 [37/26] | |

| 50/50/50 | |

| 4.545 × 6.465 |

The MB-H series provides a unique combination of high-speed and power in a small footprint. Highly productive with a high speed spindle and reduced non-cutting time, the MB-H series is built on the Okuma Thermo-Friendly Concept which enables the machine to predict and counter thermal deformation, ensuring consistent accuracy. Each machine is expandable with modular ATC magazine and APC.

Vertical machining centres

Genos M460R-VE-e

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.000 x 460 | |

| 762/460/460 | |

| 12.000 | |

| 32 | |

| 22/18.5 | |

| 40/40/32 | |

| 2.200 x 2.805 |

Based on the proven technology of the MB-V Series, the GENOS M Series of CNC vertical machining centers offers Okuma value at an economical and affordable price. Thermally stable, accurate, and rigid, these machines provide high productivity and profitability; in other words, Affordable Excellence. Equipped with Okuma’s industry leading OSP control, these environmentally-friendly vertical machining centers have the power and flexibility to deliver results time after time.

GENOS M560-V-e

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.300 x 560 | |

| 1.050/560/460 | |

| 12.000 | |

| 32 | |

| 22/18.5 | |

| 40/40/32 | |

| 2.510 x 3.100 |

Based on the proven technology of the MB-V Series, the GENOS M Series of CNC vertical machining centers offers Okuma value at an economical and affordable price. Thermally stable, accurate, and rigid, these machines provide high productivity and profitability; in other words, Affordable Excellence. Equipped with Okuma’s industry leading OSP control, these environmentally-friendly vertical machining centers have the power and flexibility to deliver results time after time.

MA-550VB

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.300 x 560 | |

| 1.300/560/560 | |

| 6.000 [12.000] | |

| 32 [48, 60] | |

| 22/15/11 | |

| 40/40/30 | |

| 3.200 x 2.855 |

When you want to harness the full potential of power and speed, look no further than the MA-V Series. Designed with a dual way system, the MA-V Series combines the heavy-duty cutting power of box ways with the high-speed capability of the linear guide. This unique approach creates a versatile machine able to accommodate multiple cutting and finishing needs on a single machine. Extreme power must be balanced by control. Okuma designed the box ways on the MA-V Series with an internal coolant system to eliminate overheating. A geared headstock provides maximum torque and power throughout the entire RPM range for heavy machining.

MA-650VB

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.530 x 660 | |

| 1.530/660/610 | |

| 6.000 [12.000] | |

| 32 [48, 60] | |

| 22/15/11 | |

| 40/40/30 | |

| 3.750 x 3.128 |

When you want to harness the full potential of power and speed, look no further than the MA-V Series. Designed with a dual way system, the MA-V Series combines the heavy-duty cutting power of box ways with the high-speed capability of the linear guide. This unique approach creates a versatile machine able to accommodate multiple cutting and finishing needs on a single machine. Extreme power must be balanced by control. Okuma designed the box ways on the MA-V Series with an internal coolant system to eliminate overheating. A geared headstock provides maximum torque and power throughout the entire RPM range for heavy machining.

MB-46VA / B

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 760 x 460 | |

| 560/460/460 | |

| 8.000 [15.000/20.000/25.000/35.000] | |

| 20 [32, 48] | |

| 11/7.5 [22/18,5, 30/22, 15/11] | |

| 40/40/32 | |

| 1.900/1.950 x 2.715 |

The basis for all Okuma vertical machining centers, the MB-V Series sets the bar for efficiency, utility, and high speed. Among the fastest in the industry. An impressive thermal stability and zero table overhang allow for tight tolerances and extreme accuracy. The ergonomic front-access design of the Okuma MB-V Series requires minimal floor space while yielding maximum results. In addition, the MB-V Series is environmentally friendly, requiring no hydraulic fluid. Construction optimisation based on FEM analysis and a rapid spindle traverse with Hi-G acceleration combine to create a solid, nimble machine that delivers on its promise of speed and accuracy, time and time again.

MB-56VA / B

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.300 x 560 | |

| 1.050/560/460 | |

| 8.000 [15.000/20.000/25.000/35.000] | |

| 20 [32,48] | |

| 11/7.5 [22/18.5, 15/11] | |

| 40/40/32 | |

| 2.470 x 3.100 |

The basis for all Okuma vertical machining centers, the MB-V Series sets the bar for efficiency, utility, and high speed. Among the fastest in the industry. An impressive thermal stability and zero table overhang allow for tight tolerances and extreme accuracy. The ergonomic front-access design of the Okuma MB-V Series requires minimal floor space while yielding maximum results. In addition, the MB-V Series is environmentally friendly, requiring no hydraulic fluid. Construction optimisation based on FEM analysis and a rapid spindle traverse with Hi-G acceleration combine to create a solid, nimble machine that delivers on its promise of speed and accuracy, time and time again.

MB-66VA / B

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.530 x 660 | |

| 1.500/660/660 | |

| 8.000 [15.000, 20.000, 25.000] | |

| 20 [32, 48] | |

| 11/7.5 [22/18.5, 30/22] | |

| 40/40/32 | |

| 2.940 x 3.265 |

The basis for all Okuma vertical machining centers, the MB-V Series sets the bar for efficiency, utility, and high speed. Among the fastest in the industry. An impressive thermal stability and zero table overhang allow for tight tolerances and extreme accuracy. The ergonomic front-access design of the Okuma MB-V Series requires minimal floor space while yielding maximum results. In addition, the MB-V Series is environmentally friendly, requiring no hydraulic fluid. Construction optimisation based on FEM analysis and a rapid spindle traverse with Hi-G acceleration combine to create a solid, nimble machine that delivers on its promise of speed and accuracy, time and time again.

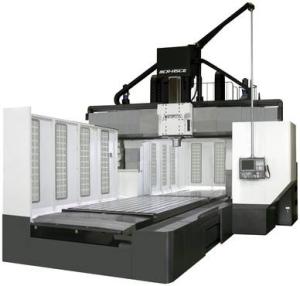

MCR-A5CII

|

Double Columns

Okuma Europe GmbH

Vertical machining centres

| 2.150 - 3.650 | |

| 1.500 x 3.000 - 3.000 x 12.000 | |

| 3.200/2.600/800 - 12.200/4.100/1.200 | |

| 4.000 [6.000, 10.000] | |

| 50 [80, 100, 120, 180] | |

| 26/22 [30/22] | |

| 30/32/20 | |

| 6.180 x 8.430 - 7.780 x 28.420 |

The MCR-A5CII is a high-speed double column machining center with compact auto loading/unloading attachments for true 5-sided machining in a compact footprint. The solid double column construction ensures greater rigidity and closer tolerances, making this machine well-suited for the efficient machining of general parts and rapid die/mould jobs.

MCR-BIII

|

Double Columns

Okuma Europe GmbH

Vertical machining centres

| 2.050 - 3.550 | |

| 2.800 x 1.500 - 3.000 x 11.800 | |

| 3.000/2.700/800 - 12.000/4.200/1.300 | |

| 4.000 [3.600, 6.000, 8.000, 10.000] | |

| 32 [50, 72, 100, 120, 180] | |

| 30/22 [45/37, 26/22] | |

| 15/20/15 | |

| 6.995 x 8.200 - 8.780 x 27.400 |

The Okuma MCR-BIII double column machining center provides five-face machining of parts in a single, economical and efficient setup. The ram-type head features a 30 kW, 4.000 min vertical spindle for powerful cutting and rigidity. A wide variety of machining, including angular and compound angular surface machining, can be performed automatically with a single workpiece setup through the use of various attachments. Automatic tool changing to the vertical spindle or to the horizontal attachment is provided with a standard 50 tool magazine located on the side of the column, with additional tool chain capacities optional. The MCR-BIII is versatile enough to handle everything from heavy cutting to high-accuracy finishing of die/mould jobs and large, complex parts.

MCR-C

|

Double Columns

Okuma Europe GmbH

Vertical machining centres

| 2.650 - 3.650 | |

| 2.000 x 4.000 - 3.000 x 12.000 | |

| 4.200/3.200/1.050 - 12.200/4.200/1.250 | |

| 4.000 [6.000] | |

| 50 [80, 100, 120, 180] | |

| 45/37 | |

| 24/24/15 | |

| 7.810 x 10.730 - 8.710 x 28.420 |

The MCR-C double column machining center was created to meet the demand of heavy industries for high power, high torque and high productivity. The exceptionally rigid spindle delivers powerful, 5-axis cutting on a thermally stable machine that provides efficient and accurate machining of large components. The MCR-C double column machining center’s auto tool changer (ATC) and full array of available spindle heads (attachments) support the machining of all types and shapes of parts.

MCV-AII

|

Double Columns

Okuma Europe GmbH

Vertical machining centres

| 1.650 - 2.050 | |

| 1.200 x 2.100 - 1.500 x 5.100 | |

| 2.000/ 1.600 / 1.000 - 5.000/ 2.000/ 1.150 | |

| 4.000 [6.000, 10.000] | |

| 24 [50, 72, 100] | |

| 22/18,5 [22/15] | |

| 20/20/10 | |

| 4.740 x 6.000 - 5.140 x 12.200 |

The MCV-AII delivers smooth performance with the speed and power you expect from an Okuma double column machining center. This machine is perfect for streamlined machining of medium to large parts from heavy-duty cutting to fast finishing. The direct (gearless) spindle drive means less noise for better work environment and less vibration for longer tool life. Standard spindle cooler delivers consistently high accuracies while the solid double-column construction ensures flawless precision and rigidity.

MF-46VA / B

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 760 x 460 | |

| 760/560/460 | |

| 8.000 [15.000, 20.000, 25.000, 35.000] | |

| 20 [32, 48] | |

| 11/7.5 [22/18.5, 30/22, 15/11] | |

| 40/40/32 | |

| 2.406/2.456 x 3.270 |

The basis for all Okuma vertical machining centers, the MB-V Series sets the bar for efficiency, utility, and high speed. Among the fastest in the industry. An impressive thermal stability and zero table overhang allow for tight tolerances and extreme accuracy. The ergonomic front-access design of the Okuma MB-V Series requires minimal floor space while yielding maximum results. In addition, the MB-V Series is environmentally friendly, requiring no hydraulic fluid. Construction optimisation based on FEM analysis and a rapid spindle traverse with Hi-G acceleration combine to create a solid, nimble machine that delivers on its promise of speed and accuracy, time and time again.

MILLAC 761VII

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 1.800 x 720 | |

| 1.540/760/660 | |

| 4.000 [6.000, 10.000, 12.000] | |

| 36 [54] | |

| 18,5/15 [22/18.5] | |

| 16/16/16 | |

| 4.300 x 4.060 |

The MILLAC-VII Series of vertical machining centers has high machining capacity with a large range of travel. The highly rigid construction allows for powerful, high-speed, heavy-duty cutting. The main spindle, equipped with a variable speed gear head and large diameter spindle bearings, can perform heavy-duty cutting and rapid machining with large torque from low to high speeds.

MILLAC 852VII

|

Vertical Machining Centers

Okuma Europe GmbH

Vertical machining centres

| 2.200 [3.200] x 850 | |

| 2.050 [3.050]/850/750 | |

| 4.000 [6.000, 10.000, 12.000] | |

| 36 [54] | |

| 18,5/15 [22/18.5] | |

| 12/12/16 | |

| 5.460 [7.460] x 4.445 |

The MILLAC-VII Series of vertical machining centers has high machining capacity with a large range of travel. The highly rigid construction allows for powerful, high-speed, heavy-duty cutting. The main spindle, equipped with a variable speed gear head and large diameter spindle bearings, can perform heavy-duty cutting and rapid machining with large torque from low to high speeds.

Loading ...