RoboJob

Products

First in CNC Automation

RoboJob NV

Handling of workpieces

Turn-Assist Series

The most compact total solution for the loading and unloading of your CNC lathe. Our Turn-Assist Series offers you a wide range of four standard products for the automation of your lathe. These four solutions differ in dimensions, capacity and workpiece diameter. They are all very user-friendly, compact, accessible and visible: thus our Turn-Assist Series are the most compact and user-friendly loading solutions on the market. You also have the most comprehensive standard functions, so that you can get started right away with our easy-to-use controls and significantly increase your Output, Efficiency and Flexibility. With the Turn-Assist Series we offer you four different standard automations, each with specific characteristics. Within each model you have a wide choice of robot payloads, options and modular extensions. You also have the option of choosing an 'integrated' model or a 'separated' model.

Coby CNC

|

Handling of workpieces

RoboJob NV

Handling of workpieces

With Coby CNC, we offer a completely new solution to our customers. An accessible automation that combines the brains of RoboJob - rock-solid software with intuitive operating system - with the accessibility of a Cobot.

As with all RoboJob systems, Coby is an automation solution for CNC turning and milling machines. What makes it so unique is that the customer can configure, install and use it entirely independently. You will be able to buy Coby online, after which he will be shipped to you. Several tools have been developed to make that possible: an online store with practical information, 'Quick Start Guides' to unpack and get Coby up and running, and videos that visualise each step. Nothing was left to chance.

You can meet Coby in person at the EMO tradeshow in Hannover. Visit us in Hall 15, Booth B15.

As with all RoboJob systems, Coby is an automation solution for CNC turning and milling machines. What makes it so unique is that the customer can configure, install and use it entirely independently. You will be able to buy Coby online, after which he will be shipped to you. Several tools have been developed to make that possible: an online store with practical information, 'Quick Start Guides' to unpack and get Coby up and running, and videos that visualise each step. Nothing was left to chance.

You can meet Coby in person at the EMO tradeshow in Hannover. Visit us in Hall 15, Booth B15.

Servogripper

|

Handling of workpieces

RoboJob NV

Handling of workpieces

To allow even more flexibility and autonomy, RoboJob has developed the Servogripper.

Just like any other gripper, this gripper too has 2 sides: one to handle a raw workpiece, and the other to handle the finished workpiece. Workpieces can include, but are not limited to discs, blocks and shafts. But the Servogripper can also handle fixtures, chuckfaces, individual jaws of a clamping device and collets.

Every gripperside can be docked and undocked, and by doing so the robot can change its grippertools automatically. The gripperbody has 2 integrated FANUC servo engines to allow for the highest clamping force and a streamlined design. The clamping force can be adjusted automatically.

The Servogripper can be fitted with automatically adjustable gripper jaws, which allow the robot to automatically adjust himself to the workpiece he is handling. In one single process, the robot can therefore handle a wide variety of workpieces in different shapes and sizes without any manual intervention op the operator. As a result, you can create much more autonomy in your production process.

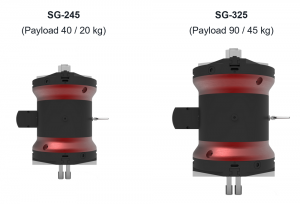

The Servogripper is available in 2 models:

Just like any other gripper, this gripper too has 2 sides: one to handle a raw workpiece, and the other to handle the finished workpiece. Workpieces can include, but are not limited to discs, blocks and shafts. But the Servogripper can also handle fixtures, chuckfaces, individual jaws of a clamping device and collets.

Every gripperside can be docked and undocked, and by doing so the robot can change its grippertools automatically. The gripperbody has 2 integrated FANUC servo engines to allow for the highest clamping force and a streamlined design. The clamping force can be adjusted automatically.

The Servogripper can be fitted with automatically adjustable gripper jaws, which allow the robot to automatically adjust himself to the workpiece he is handling. In one single process, the robot can therefore handle a wide variety of workpieces in different shapes and sizes without any manual intervention op the operator. As a result, you can create much more autonomy in your production process.

The Servogripper is available in 2 models:

- The SG-245 can be mounted on a FANUC robot with 70kg payload and it handle workpieces up to 40kg in a single-load cycle or 20kg in a double-load cycle. The SG-245 can grab discs as well as blocks internally in the range from Ø 50 to 165 mm, from Ø 165 to 280 mm or from Ø 280 to 395 mm. It can also grab round products as well as blocks externally in the range from Ø 10 to 125 mm, from Ø 125 to 240 mm or from Ø 240 to 355 mm.

- The SG-325 can be mounted on a FANUC robot with 165kg payload and it handle workpieces up to 90kg in a single-load cycle or 45kg in a double-load cycle. The SG-325 can grab discs as well as blocks internally in the range from Ø 60 to 215 mm, from Ø 215 to 370 mm or from Ø 370 to 525 mm. It can also grab round products as well as blocks externally in the range from Ø 10 to 165 mm, from Ø 165 to 320 mm or from Ø 320 to 475 mm.

Mill-Assist Series

|

Handling of workpieces

RoboJob NV

Handling of workpieces

The most compact total solution for the loading and unloading of your CNC milling machine. Our Mill-Assist Series offers you a wide range of standard products for the automation of your milling machine. These solutions differ in dimensions, capacity and workpiece dimensions. They are all very user-friendly, compact, accessible and visible: the Mill-Assist Series are the most compact and user-friendly loading solutions on the market. You also have the most comprehensive standard functions, so that you can get started right away with our easy-to-use controls and significantly increase your Output, Efficiency and Flexibility. With the Mill-Assist Series we offer you various standard automations, each with specific characteristics. Within each model you have a wide choice of robot payloads, options and modular extensions.

At EMO, will show you a modular extension that allows you to load and unload HWR SOLIDGrip vises. With one automation, you can now load both workpieces and vises.

At EMO, will show you a modular extension that allows you to load and unload HWR SOLIDGrip vises. With one automation, you can now load both workpieces and vises.

Tower

|

Other equipment for workpiece or tool handling

RoboJob NV

Handling of workpieces

Are you up to speed with Industry 4.0, digital transformation, and are you aiming for maximum autonomy for your machine park? Stop looking. The Tower can achieve 72 hours of unmanned machining.

A servo gripper? Check. One robot serving 2 machines? Absolutely. Even a turning lathe and a milling machine if possible. You can do it all with the same user-friendly software that you are used to from RoboJob. Including Job Scheduler, pallet gripper and much more.

The Tower is a revolutionary total solution for the loading and unloading of your CNC turning lathe, milling machine or turning/milling combination. Like with our other automation solutions, using the Tower you can also load and unload the workpieces in your CNC machine. You can do this on both a CNC-controlled lathe, milling machine and a turning/milling combination. But there's still so much more ... This universal concept can also load and unload pallets, and ultimately also provide your CNC machine with all the necessary clamping devices and tools. With the Tower you have an automation unit that allows your CNC machine to continue working unmanned for several days and/or allows automatic production of single pieces.

A servo gripper? Check. One robot serving 2 machines? Absolutely. Even a turning lathe and a milling machine if possible. You can do it all with the same user-friendly software that you are used to from RoboJob. Including Job Scheduler, pallet gripper and much more.

The Tower is a revolutionary total solution for the loading and unloading of your CNC turning lathe, milling machine or turning/milling combination. Like with our other automation solutions, using the Tower you can also load and unload the workpieces in your CNC machine. You can do this on both a CNC-controlled lathe, milling machine and a turning/milling combination. But there's still so much more ... This universal concept can also load and unload pallets, and ultimately also provide your CNC machine with all the necessary clamping devices and tools. With the Tower you have an automation unit that allows your CNC machine to continue working unmanned for several days and/or allows automatic production of single pieces.