A lot of shavings in just a short time. In addition, a long service life, the highest precision and accuracy: Users of RÖHM products are used to this, and exactly that is offered by the clamping and gripping specialist with its KFD-HS power chucks. “We know the high demands that are placed on the work material in machining practice. Our power chucks are designed to meet these needs,” says Fabian Baur, the responsible product manager at RÖHM.

Power chucks have to mount parts in just a few seconds, clamp them reliably, accurately and stably, and then release them again reliably after machining. It doesn’t matter whether it is for machining rods and tubes or for machining flange-like workpieces, high clamping forces are usually required. Baur explains how this is realised: “The centrifugal forces that occur during machining are absorbed in such a way that they only have a minor effect on the clamping force.” The drop in clamping force is very low even at extremely high speeds. “This is ensured by our particular type of wedge hook connection.” That is because the proven system enables the highest clamping forces with the highest clamping accuracy at the same time.

Especially when machining rod material, the KFD-HS is characterised not only by its high flexibility due to the large passageway, but it also boosts efficiency thanks to high cycle rates. “Economical manufacturing means automated manufacturing,” says Baur. It is necessary to cover the biggest possible range of parts in the fewest possible operations and with minimum tooling times.

There is indeed great potential in the KFD-HS, the direct interface to the workpiece. Thanks to the enormous clamping forces and highest resilience, even the fiddliest clamping tasks can be solved economically. “Precision machining, process stability when changing the workpiece, as well as the highest resilience in 24/7 operation are simply part of it,” says Baur. Specifically, high rigidity is achieved through the screw connection of the chuck body and chuck flange. That way, this chuck type offers optimum conditions for precise machining of both shaft and flange types of workpieces.

In short, the long service life, highest accuracy and reliability as well as decades of experience and the knowledge of power chucks make the KFD-HS from RÖHM so successful.

RÖHM

News

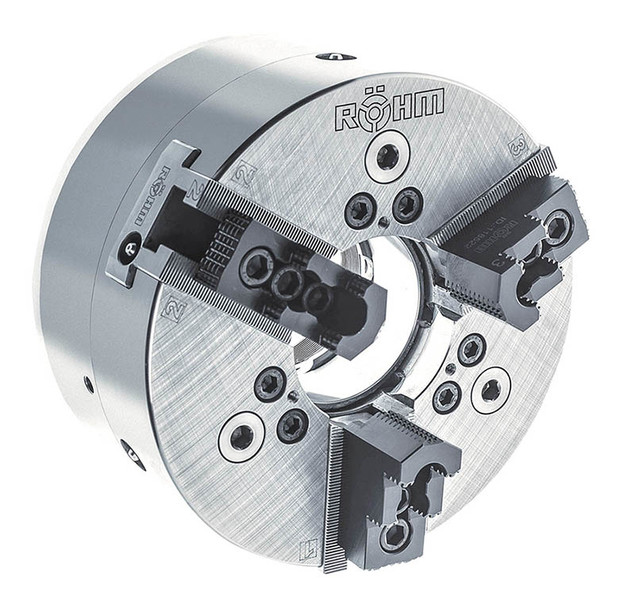

The KFD-HS power chuck from RÖHM

Responsible for the content of this press release: RÖHM GmbH

|

Contact

RÖHM GmbH

Heinrich-Röhm-Str. 50 89567 Sontheim

Germany

Germany Route planner

Route planner