ROEMHELD will present an integrated concept for handling and changing forming and punching tools at Blechexpo 2021. With this concept, dies or moulds can be quickly and safely stored, transported to the press and positioned, centred and clamped on the machine table.

Furthermore, the set-up time optimiser shows two new products: an electrically driven changing console for dies or moulds up to 50 t and a double-acting arch clamp for flat clamping edges with clamping forces of up to 450 kN and mechanical lock.

The trade fair premieres and an overview of the clamping and handling technology can be seen in Hall 8 at Stand 8506.

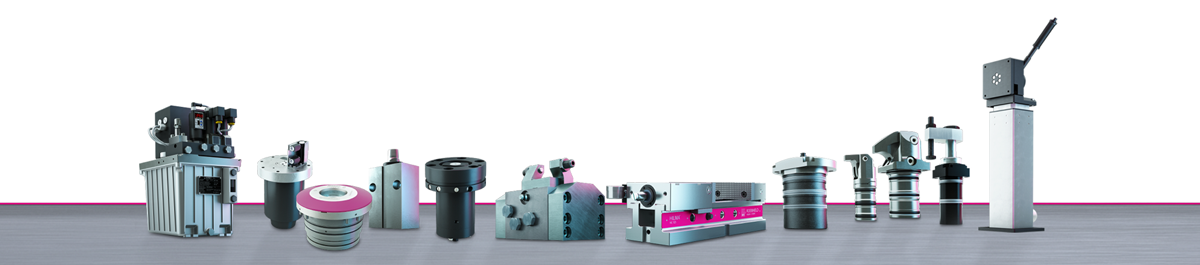

Extensive selection of components for almost every clamping task

For integrated die or mould handling, coordinated components for the entire process chain can be combined individually, depending on the task. The wide range includes numerous versions of rack systems, transport carts and bars, carrying and changing consoles, and clamping elements up to magnetic clamping plates. These components enable efficient die or mould handling for almost all requirements.

Move dies or moulds safely and effortlessly

Different rack types can be assembled to the desired size. The dies or moulds are transported from the warehouse to the press with changing carts manually or electrically powered by battery. They can be easily inserted into the machine via manually or electrically driven consoles. Roller and ball bars integrated into storage floors, transport and machine tables, ensure that even heavy dies or moulds can be moved effortlessly by hand over surfaces.

A uniform docking system fitted to all racks, transport carts and consoles ensures safe handling throughout the entire process chain. Thus, dies and moulds can only be moved once the components are firmly connected.

Clamping dies or moulds in all variations

A wide range of mechanical, hydraulic, electro-mechanical and magnetic clamping systems are available for positioning, centring and clamping the dies or moulds in the press.

Setting up is particularly safe and fast with the help of magnetic clamping technology, where the clamping process only takes a few seconds. An electrical impulse triggers clamping at the touch of a button at the control unit – without an operator having to touch the press and ram. Magnetic clamping plates can also be used universally for all ferromagnetic dies or moulds – regardless of their size and geometry. Therefore, it is also unnecessary to standardise dies, moulds and clamping edges. For the maintenance of the magnetic clamping technology, ROEMHELD also offers a comprehensive service package.

ROEMHELD: Set-up time optimiser for sheet metal forming, plastic and rubber processing

With its extensive portfolio of die clamping technology, the set-up time optimiser ROEMHELD solves almost every clamping task in sheet metal forming, plastics and rubber processing. The magnetic, hydraulic and electro-mechanical clamping systems are versatile and contribute to making processes in single and series production of nearly all industries more efficient and economical. Products for die change such as die changing cart, roller bars and driven carrying consoles complete the product range.

Germany

Germany