Your solution provider in clamping and handling technology

ROEMHELD at Blechexpo: the first in-house magnetic clamping system and innovative die changing carts

Laubach, 8 September 2025. ROEMHELD is presenting several innovations at Blechexpo that help to reduce set-up times in sheet metal forming and increase operational reliability.

R-MAG-M, the supplier's first developed magnetic clamping system for sheet metal forming, is celebrating its trade fair premiere. It is the first to offer a clamping force display and interchangeable magnetic poles. With both functions, which were requested by many customers, the clamping technology specialist is currently unrivalled in sheet metal forming.

Two further electrically powered innovations facilitate die transport: an RW 1000-ELMO for dies weighing up to 1,000 kg and the RWT for loads weighing up to 4,000 kg.

The Flexline-R quick-clamping system for automatically clamping dies of different sizes on the press ram will also be on display for the first time at a trade fair – as will the 24-volt DC version, the "Green Edition".

ROEMHELD will be presenting these new products and an overview of its complete portfolio for die change in forming technology at Blechexpo from 21 to 24 October 2025 in Stuttgart in Hall 8, Stand 8505.

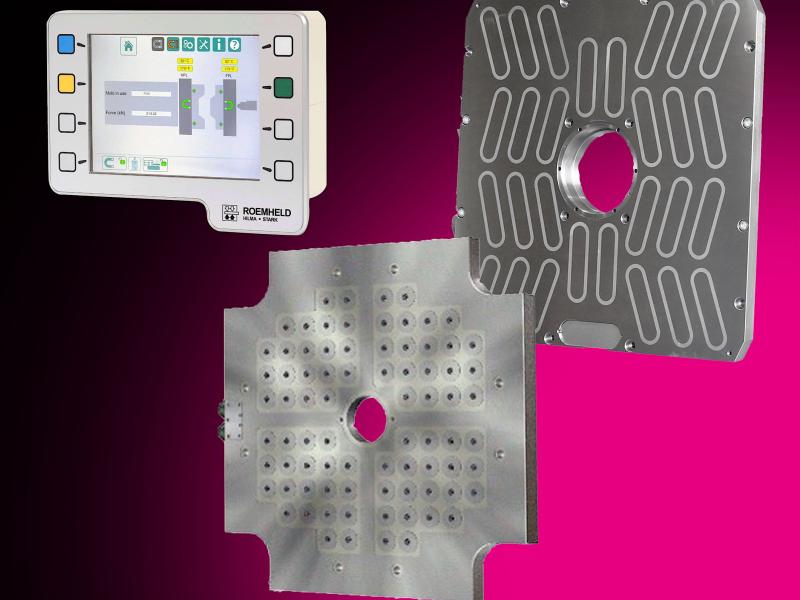

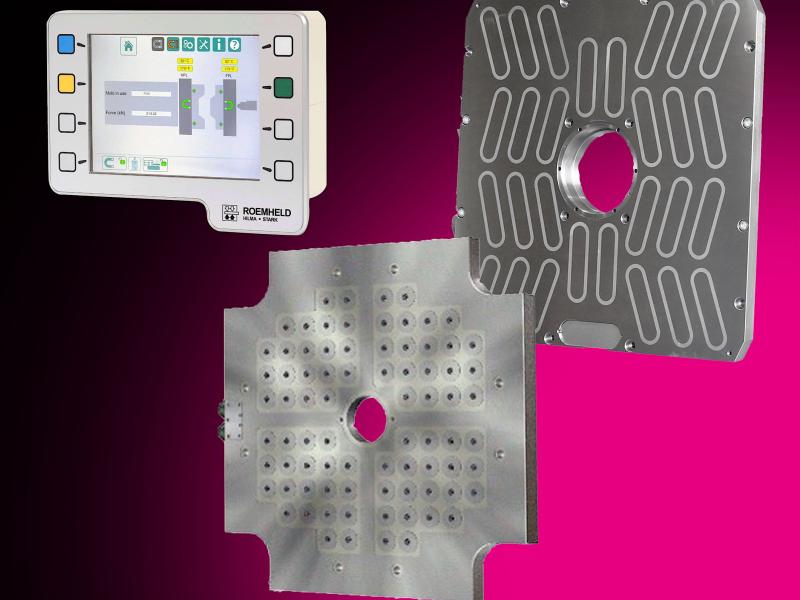

R-MAG-M: The first magnetic clamping system with clamping force display

The electro permanent magnetic clamping system R-MAG-M clamps dies of various sizes and geometries fully automatically and without distortion in seconds and guarantees a secure hold even in the event of a power failure.

A new feature is an integrated clamping force display for greater process reliability. In addition, various sensors such as temperature sensors, position switches and flux measurement sensors monitor the system during production. These control functions and high holding forces guarantee secure die clamping.

The replaceable magnetic poles are innovative. The technology simplifies maintenance and reduces downtime to a minimum, as defective poles can be replaced on site. A modern 8-inch colour display and an integrated remote maintenance module round off the new R-MAG-M.

ROEMHELD designs and develops all magnetic clamping systems to customer specifications in Europe.

RW 1000 ELMO, "Electric Motion": Fully electric drive for greater convenience

A new version of the RW 1000 series die changing carts for loads up to 1,000 kg expands the proven model series with a fully electric variant. Unlike its manually driven sister products, both the lift and the drive of the new RW 1000 ELMO are purely electrically operated.

The "B" version with an additional integrated docking strip at the front is also available. This bridges any interfering edges on the press table, making it easier to move the dies onto the machine table.

Heavy-duty specialist: RWT die changing cart for up to 4,000 kg

For particularly heavy loads, ROEMHELD is presenting the new RWT die changing cart at the trade fair. The electric vehicle with radio remote control for ergonomic die handling of loads up to 4,000 kg is a fully integrated transport solution.

It combines a powerful drive with an electro-hydraulic lifting platform, an integrated push-pull system, hydraulic ball bars and docking devices. This enables the safe transport, effortless automatic extension and retraction, and precise positioning of heavy dies. A radio remote control g and modular equipment ensure ergonomic handling and high flexibility.

Flexline-R and Green Edition

The Flexline-R quick-clamping system is based on the proven Flexline models and has been optimised for high loads. It is particularly suitable for automated press lines with frequent die changes. At its core is a welded stainless steel pull-push chain that offers maximum stability and durability. Reinforced brackets, stainless steel components and an emergency release on the motor increase operational safety. Precise sensors monitor the positions of the clamping element and, optionally, the end position of the chain.

Flexline R is available with two adjustment ranges and with various hollow piston cylinders offering clamping forces of up to 104 kN. The compact design, low weight and use of low-maintenance modules facilitate installation and servicing and reduce downtime. Thanks to the integrated energy and signal line, a separate guide is not required.

The Green Edition is also available as a variant with 24-volt DC power supply, which is compatible worldwide and eliminates the need for retrofitting.

Complete solutions from clamping to changing technology

With these new products, ROEMHELD is expanding its range of user-friendly, safe and efficient solutions for sheet metal forming. Visitors to the booth will receive a comprehensive overview of modern set-up time optimisation – from clamping and transport to die change.

About ROEMHELD:

Whether aircraft, automobiles, machine tools or smartphone cases: ROEMHELD technologies and products have been used in the manufacture of numerous industrial goods and consumer goods for over 80 years.

Innovative and smart clamping technology solutions for workpieces and dies in forming technology and plastics processing form the core of the continuously growing portfolio. This is complemented by components and systems for assembly and handling technology, drive technology and automation, as well as interlocks for rotors of wind turbines.

In addition to a constantly growing range of more than 25,000 catalogue items, ROEMHELD specialises in the development and manufacture of customer-specific solutions and is internationally recognised as one of the market and quality leaders.

Innovation through tradition: ROEMHELD has its origins in the Friedrichshütte foundry, founded in 1707, which still belongs to the ROEMHELD Group today and is one of the oldest active industrial companies in Germany.

The owner-managed group of companies employs around 500 people at its three locations in Laubach, Wilnsdorf and Rankweil/Austria and is represented in over 50 countries with service and sales companies. With customers primarily from the mechanical engineering, automotive, aerospace and agricultural industries, ROEMHELD generates annual sales of more than €90 million.

Laubach, 8 September 2025. ROEMHELD is presenting several innovations at Blechexpo that help to reduce set-up times in sheet metal forming and increase operational reliability.

R-MAG-M, the supplier's first developed magnetic clamping system for sheet metal forming, is celebrating its trade fair premiere. It is the first to offer a clamping force display and interchangeable magnetic poles. With both functions, which were requested by many customers, the clamping technology specialist is currently unrivalled in sheet metal forming.

Two further electrically powered innovations facilitate die transport: an RW 1000-ELMO for dies weighing up to 1,000 kg and the RWT for loads weighing up to 4,000 kg.

The Flexline-R quick-clamping system for automatically clamping dies of different sizes on the press ram will also be on display for the first time at a trade fair – as will the 24-volt DC version, the "Green Edition".

ROEMHELD will be presenting these new products and an overview of its complete portfolio for die change in forming technology at Blechexpo from 21 to 24 October 2025 in Stuttgart in Hall 8, Stand 8505.

R-MAG-M: The first magnetic clamping system with clamping force display

The electro permanent magnetic clamping system R-MAG-M clamps dies of various sizes and geometries fully automatically and without distortion in seconds and guarantees a secure hold even in the event of a power failure.

A new feature is an integrated clamping force display for greater process reliability. In addition, various sensors such as temperature sensors, position switches and flux measurement sensors monitor the system during production. These control functions and high holding forces guarantee secure die clamping.

The replaceable magnetic poles are innovative. The technology simplifies maintenance and reduces downtime to a minimum, as defective poles can be replaced on site. A modern 8-inch colour display and an integrated remote maintenance module round off the new R-MAG-M.

ROEMHELD designs and develops all magnetic clamping systems to customer specifications in Europe.

RW 1000 ELMO, "Electric Motion": Fully electric drive for greater convenience

A new version of the RW 1000 series die changing carts for loads up to 1,000 kg expands the proven model series with a fully electric variant. Unlike its manually driven sister products, both the lift and the drive of the new RW 1000 ELMO are purely electrically operated.

The "B" version with an additional integrated docking strip at the front is also available. This bridges any interfering edges on the press table, making it easier to move the dies onto the machine table.

Heavy-duty specialist: RWT die changing cart for up to 4,000 kg

For particularly heavy loads, ROEMHELD is presenting the new RWT die changing cart at the trade fair. The electric vehicle with radio remote control for ergonomic die handling of loads up to 4,000 kg is a fully integrated transport solution.

It combines a powerful drive with an electro-hydraulic lifting platform, an integrated push-pull system, hydraulic ball bars and docking devices. This enables the safe transport, effortless automatic extension and retraction, and precise positioning of heavy dies. A radio remote control g and modular equipment ensure ergonomic handling and high flexibility.

Flexline-R and Green Edition

The Flexline-R quick-clamping system is based on the proven Flexline models and has been optimised for high loads. It is particularly suitable for automated press lines with frequent die changes. At its core is a welded stainless steel pull-push chain that offers maximum stability and durability. Reinforced brackets, stainless steel components and an emergency release on the motor increase operational safety. Precise sensors monitor the positions of the clamping element and, optionally, the end position of the chain.

Flexline R is available with two adjustment ranges and with various hollow piston cylinders offering clamping forces of up to 104 kN. The compact design, low weight and use of low-maintenance modules facilitate installation and servicing and reduce downtime. Thanks to the integrated energy and signal line, a separate guide is not required.

The Green Edition is also available as a variant with 24-volt DC power supply, which is compatible worldwide and eliminates the need for retrofitting.

Complete solutions from clamping to changing technology

With these new products, ROEMHELD is expanding its range of user-friendly, safe and efficient solutions for sheet metal forming. Visitors to the booth will receive a comprehensive overview of modern set-up time optimisation – from clamping and transport to die change.

About ROEMHELD:

Whether aircraft, automobiles, machine tools or smartphone cases: ROEMHELD technologies and products have been used in the manufacture of numerous industrial goods and consumer goods for over 80 years.

Innovative and smart clamping technology solutions for workpieces and dies in forming technology and plastics processing form the core of the continuously growing portfolio. This is complemented by components and systems for assembly and handling technology, drive technology and automation, as well as interlocks for rotors of wind turbines.

In addition to a constantly growing range of more than 25,000 catalogue items, ROEMHELD specialises in the development and manufacture of customer-specific solutions and is internationally recognised as one of the market and quality leaders.

Innovation through tradition: ROEMHELD has its origins in the Friedrichshütte foundry, founded in 1707, which still belongs to the ROEMHELD Group today and is one of the oldest active industrial companies in Germany.

The owner-managed group of companies employs around 500 people at its three locations in Laubach, Wilnsdorf and Rankweil/Austria and is represented in over 50 countries with service and sales companies. With customers primarily from the mechanical engineering, automotive, aerospace and agricultural industries, ROEMHELD generates annual sales of more than €90 million.