Your solution provider in clamping and handling technology

ROEMHELD at EMO 2025: clamping technology that grows with you

Clearly positioned: clamping technology that grows with you

At EMO 2025, the ROEMHELD Group will demonstrate how clamping technology needs to be thought of today: not as a rigid element in the workpiece area, but as a convertible solution with connections to digital processes, flexible manufacturing environments and specific customer requirements. With practical further developments in workpiece clamping and several technological innovations in the field of automation and zero-point clamping technology, the group is positioning itself as a reliable partner and setup time optimiser for efficient production processes.

ROEMHELD will be showcasing its product portfolio and all of the group's innovations at EMO 2025 in Hanover from 22 to 26 September in Hall 4, Stand F33.

Workpiece clamping with a system

The focus of the fair presentation will include components for workpiece clamping, which impress with their continuous technical maturity and alignment with user requirements. Among other things, a new compact clamp with horizontal stroke will be on display – optimised in design for applications with limited installation space. The special kinematics allow space-saving workpiece clamping with precise positioning.

Existing technologies are also being further developed: precise, repeatable hydraulic technology remains at the core of the clamping solutions, but is increasingly being supplemented by new approaches. In cooperation with a start-up, ROEMHELD is currently working on systems that offer new options for specific applications, for example through electric drive concepts.

In addition, ROEMHELD is continuously optimising its clamping elements with regard to the dynamic requirements of digital manufacturing environments. In future, sensor-enabled products will enable integration into monitoring systems, for example for clamping position monitoring or error messages – important components for automated processes in accordance with Industry 4.0 standards. At EMO,

visitors will gain insights into the clamping technology of tomorrow.

ROEMHELD also sets standards in terms of organisation: new products in the field of workpiece clamping can be configured in a standardised manner and are usually available within a week – a plus for planning and implementation reliability in production.

New technological impulses

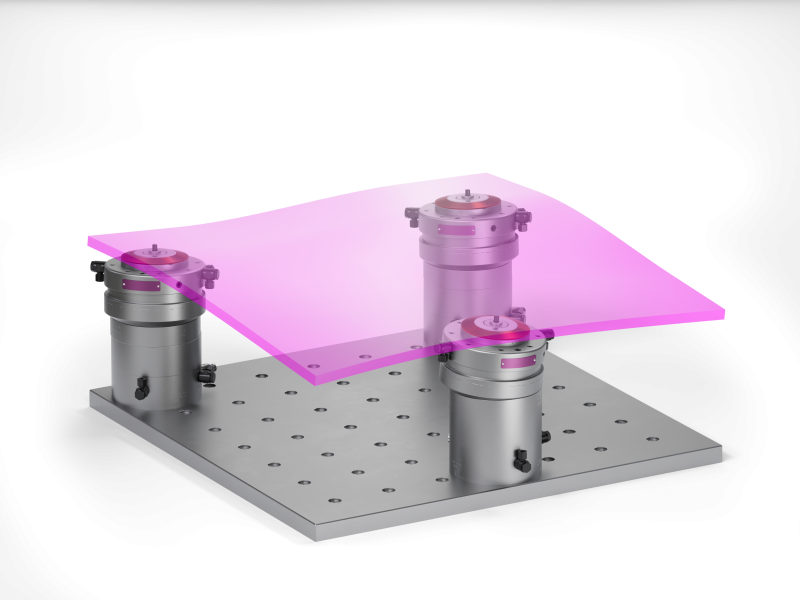

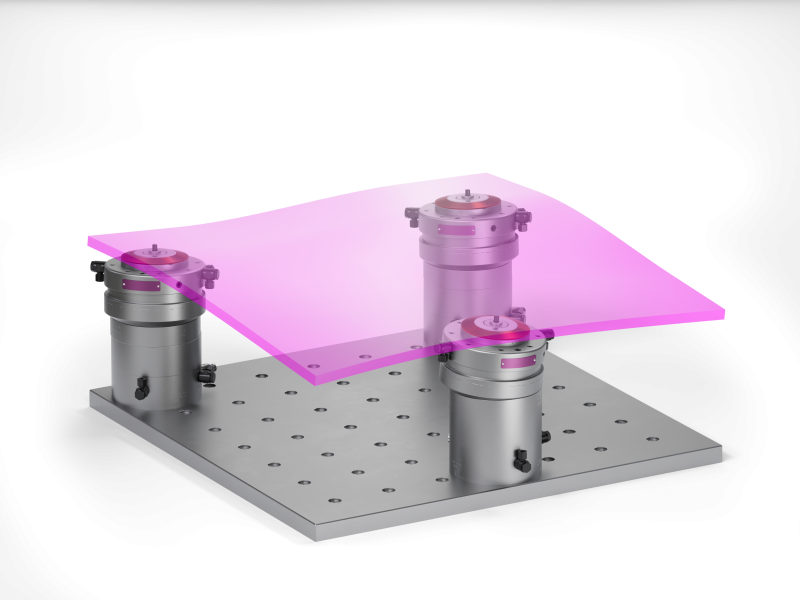

With six new products, STARK Spannsysteme – a company of the ROEMHELD Group – is bringing a breath of fresh air to zero-point and automation clamping technology. Among other things, the new STARK.spheric will be on display, which enables distortion-free clamping in volume machining – for example in aviation – thanks to pendulum compensation and length correction.

In addition, STARK is presenting the HILMA.EC 100, an electrically operated vice for hydraulic-free applications, and the redesigned HILMA.ASH 125 automation vice with sensor technology, IO-Link and support monitoring.

Further innovations include pull-in nipples for direct clamping in thin-walled components, new pendulum jaws for the secure clamping of flame-cut parts and castings, and the extension of the clamping range of the HILMA.UC 125 5-axis vice to up to one metre – including optional centre jaws for large and heavy workpieces.

All systems are designed with data integration, energy efficiency and short set-up times in mind – demonstrating how the ROEMHELD Group is consistently working on industry-specific solutions.

ROEMHELD: Precision with attitude

Where precision is crucial and no step can be spared, comprehensive, smart solutions ensure that production runs smoothly. ROEMHELD has been at home in these processes for generations.

The group of companies based in Laubach, Rankweil and Wilnsdorf develops and manufactures solutions for clamping, holding, positioning and moving workpieces and dies. These solutions are used in numerous industrial companies worldwide, e.g. in mechanical and plant engineering, in the automotive and aerospace industries, and in the manufacture of plastic components – wherever robust technology must meet efficiency.

With around 25,000 catalogue items and a high proportion of special solutions, ROEMHELD offers a broad portfolio that covers both standard and specialised applications. Technical advice, decades of application experience and customer proximity are the core strengths of the group of companies.

Clearly positioned: clamping technology that grows with you

At EMO 2025, the ROEMHELD Group will demonstrate how clamping technology needs to be thought of today: not as a rigid element in the workpiece area, but as a convertible solution with connections to digital processes, flexible manufacturing environments and specific customer requirements. With practical further developments in workpiece clamping and several technological innovations in the field of automation and zero-point clamping technology, the group is positioning itself as a reliable partner and setup time optimiser for efficient production processes.

ROEMHELD will be showcasing its product portfolio and all of the group's innovations at EMO 2025 in Hanover from 22 to 26 September in Hall 4, Stand F33.

Workpiece clamping with a system

The focus of the fair presentation will include components for workpiece clamping, which impress with their continuous technical maturity and alignment with user requirements. Among other things, a new compact clamp with horizontal stroke will be on display – optimised in design for applications with limited installation space. The special kinematics allow space-saving workpiece clamping with precise positioning.

Existing technologies are also being further developed: precise, repeatable hydraulic technology remains at the core of the clamping solutions, but is increasingly being supplemented by new approaches. In cooperation with a start-up, ROEMHELD is currently working on systems that offer new options for specific applications, for example through electric drive concepts.

In addition, ROEMHELD is continuously optimising its clamping elements with regard to the dynamic requirements of digital manufacturing environments. In future, sensor-enabled products will enable integration into monitoring systems, for example for clamping position monitoring or error messages – important components for automated processes in accordance with Industry 4.0 standards. At EMO,

visitors will gain insights into the clamping technology of tomorrow.

ROEMHELD also sets standards in terms of organisation: new products in the field of workpiece clamping can be configured in a standardised manner and are usually available within a week – a plus for planning and implementation reliability in production.

New technological impulses

With six new products, STARK Spannsysteme – a company of the ROEMHELD Group – is bringing a breath of fresh air to zero-point and automation clamping technology. Among other things, the new STARK.spheric will be on display, which enables distortion-free clamping in volume machining – for example in aviation – thanks to pendulum compensation and length correction.

In addition, STARK is presenting the HILMA.EC 100, an electrically operated vice for hydraulic-free applications, and the redesigned HILMA.ASH 125 automation vice with sensor technology, IO-Link and support monitoring.

Further innovations include pull-in nipples for direct clamping in thin-walled components, new pendulum jaws for the secure clamping of flame-cut parts and castings, and the extension of the clamping range of the HILMA.UC 125 5-axis vice to up to one metre – including optional centre jaws for large and heavy workpieces.

All systems are designed with data integration, energy efficiency and short set-up times in mind – demonstrating how the ROEMHELD Group is consistently working on industry-specific solutions.

ROEMHELD: Precision with attitude

Where precision is crucial and no step can be spared, comprehensive, smart solutions ensure that production runs smoothly. ROEMHELD has been at home in these processes for generations.

The group of companies based in Laubach, Rankweil and Wilnsdorf develops and manufactures solutions for clamping, holding, positioning and moving workpieces and dies. These solutions are used in numerous industrial companies worldwide, e.g. in mechanical and plant engineering, in the automotive and aerospace industries, and in the manufacture of plastic components – wherever robust technology must meet efficiency.

With around 25,000 catalogue items and a high proportion of special solutions, ROEMHELD offers a broad portfolio that covers both standard and specialised applications. Technical advice, decades of application experience and customer proximity are the core strengths of the group of companies.