More efficiency and safety - even in little space

Laubach, in February 2014. ROEMHELD presents at this year's Metav from March 11 to15 in Düsseldorf a number of new products from the manufacturing and workpiece clamping technology. The main focus is on components for time-saving set up, clamping in confined spaces and electrically driven elements. The new products include for example bore clamps for direct clamping of components without adapter plates. Also shown are space-saving swing clamps without swing stroke and compact clamps.

In addition, there are electrical clamping elements using the zero-point clamping system STARK SPEEDY, as well as a safety module for wireless pressure monitoring.

Many other exhibits provide an overview of the wide range of ROEMHELD workpiece clamping technology. The Company expects their visitors in Hall 14, Stand D 43.

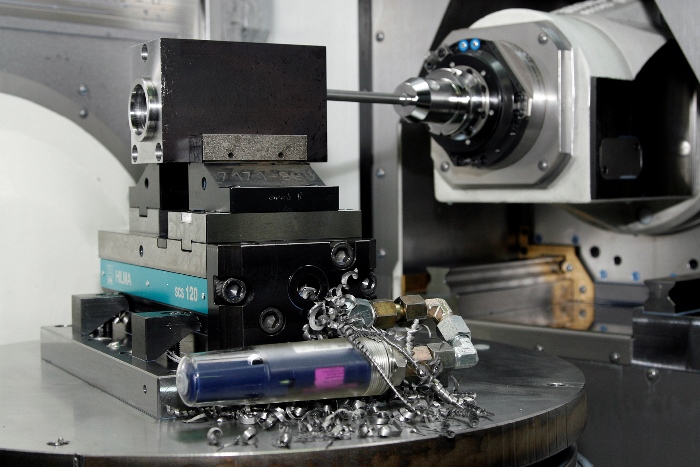

Direct clamping and 5-sided machining of components with bore holes

With the new bore clamp, ROEMHELD shows a revised direct clamping element that leads to increased productivity thanks to shorter set-up times. The elements are particularly suitable for positioning and clamping of workpieces with bore holes from diameter 6.6 to 17.7 mm in the support face. A positive air pressure connection avoids the penetration of liquids and swarf. Bore clamps offer an alternative to component clamping with customized adaptor plates. The direct loading of the workpiece in the fixture allows 5-sided machining. At the stand, ROEMHELD shows two different bore clamps to clamp a cylinder head for multi-sided machining.

New: Compact clamps with flange at the bottom

The increasing share of sales of multi-axis machines, the advancing automation and the desire to efficiently produce parts families boost the demand for space-saving clamping solutions. For use in confined areas, ROEMHELD offers a wide selection of compact clamps that will be extended by two innovations at the Metav. There will be

a new variant of the compact clamp with bottom flange that increases the field of possible applications. The hydraulically-driven components offer the advantage that the clamping points are free for loading and unloading. For swing in already a small recess at the workpiece is sufficient.

Optimised and low-priced swing clamps without axial stroke

Newly revised and available at a lower price is the compact swing clamp without swing stroke. The hydraulically-operated, double-acting clamping element swings the clamping arm in one level. Thus, space-saving clamping of the workpieces can be made in recesses, which are only slightly higher than the clamping arm. These elements with reinforced swing mechanism are available in numerous versions, e.g. with clockwise or counterclockwise swing motion or as variant with electrical or pneumatic position monitoring.

Complex hydraulic clamping devices in confined spaces can be controlled with a valve combination also shown by ROEMHELD at the Metav. All control and pressure valves are firmly installed, so that the costs for piping will be minimized and the space required will be saved.

Electric and zero-point clamping is also possible within one element

From the series of the zero point clamping systems and electrical clamping means of the etec series ROEMHELD shows, inter alia, the compact STARK SPEEDY etec with an insertion force of 7 kN and a retention force of 38 kN. It excels by short clamping and unclamping times and can be easily combined with other hydraulic and pneumatic zero point clamping systems and is also safe in the event of power failure due to the self-locking function. The diverse possible position monitorings contribute to a high process safety. The SPEEDY etec can be easily loaded thanks to the third-hand function.

Protection against machine damage

A wireless pressure monitoring guarantees more safety because of the early recognition of a pressure drop in hydraulic clamping fixtures and thus provides the protection against machine damages. Pressures up to 500 bar can be monitored with radio transmission and are shown at a RS485 interface as an analogue or digital signal. Monitoring is possible up to a distance of 300 meters to the machine.

Responsible for the content of this press release: Römheld GmbH

Germany

Germany