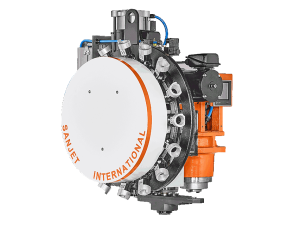

Sanjet International Co., Ltd.

Products

Automatic Tool Changer / Change by Sanjet

Sanjet International Co. Ltd

Tool changers and magazines

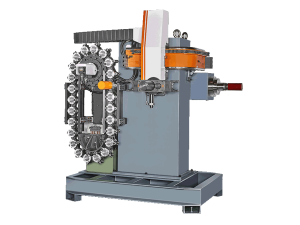

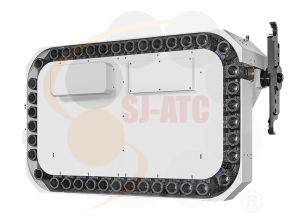

DVCA - CHAIN GRIPPER TYPE TOOL MAGAZINE

1. Continuous track design with smooth operation and low gap.

2. Original transmission eliminates chordal action during chain operation.

3. Modular design, tool loading capacity can be customized.

4. System integration without additional tool changing PLC editing requirement.

5. Connecting any brand of controller by I/O link.

Product Origin: Taiwan

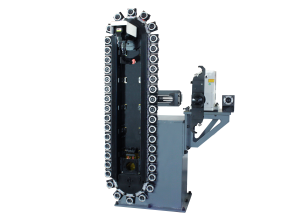

DVC09 - CHAIN GRIPPER TYPE TOOL MAGAZINE

|

For Double-Column Machining

Sanjet International Co. Ltd

Tool changers and magazines

1. Exclusively designed connection between the tool chain and the tool gripper provides extreme smoothness and stability for the tool chain running.

2. Exclusively using high precision and low backlash reducer in combination with rearmount servo motor drive that ensures uniform gravity distribution and convenient for motor replacement.

Product Origin: Taiwan

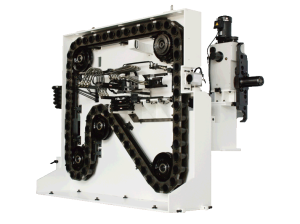

DVC2 - CHAIN GRIPPER TYPE TOOL MAGAZINE

|

Tool changers and magazines

Sanjet International Co. Ltd

Tool changers and magazines

1. The exclusive use of the Sanjet tool chain effectively reduces the tool chain gap and repeat positioning accuracy is high.

2. Exclusively using high precision and low backlash reducer in combination with rear-mount servo motor drive that ensures uniform gravity distribution and convenient for motor replacement

Product Origin: Taiwan

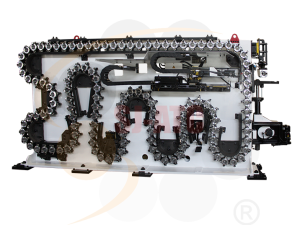

DVCAB - Chain Type With Electronic Braker And Tool Arm

|

For Double-Column Machining

Sanjet International Co. Ltd

Tool changers and magazines

1. Modular design of tool magazine and tool running component can be replaced and customized according to customers? needs.

2. Unique design of a pedrail type tool chain. The tool chain runs in a rolling way to reduce abrasions and running noises, and prolong service life.

3. Servo motor or induction motor is optional.

4. The buffering function of electronic braker reduces shocks caused by the magazine operation.

5. The tool change time is stable, won?t be affected by varieties of power supply from different areas and countries.

Product Origin: Taiwan

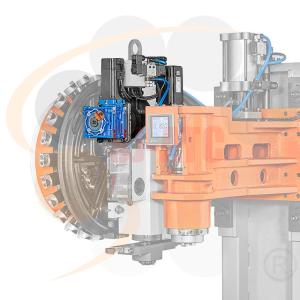

HVC - TOOL MAGAZINE WITH HYDRAULIC ROBOTIC ARM

|

For Double-Column Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. A transmission mechanism consisting of servo motor and low backlash speed reducer.

2. A modular transmission mechanism consisting of hydraulic motor and positioning hydraulic cylinder.

Product Origin: Taiwan

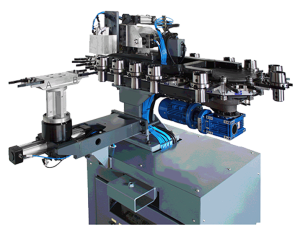

HBC2 - CHAIN TYPE TOOL WITH HYDRAULIC RAIL ROBOTIC ARM ?

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. Feature:

Sanjet original design toolchain: Magazine chain operates by rolling, which reduce mechanism resistance, increase lifespan, and reduce toolchain operation noise effectively. Dual chain design eliminates gap in tool transporting structure and provides precise positioning.

2. Rail design?

V shape steel rail design increases rail rigidity. Auto-guide roller design is using fewer rollers and having auto gap making up running mechanism which increases product lifespan.

Product Origin: Taiwan

CFH - HORIZONTAL SQUARE CHAIN TYPE TOOL MAGAZINE

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

For Horizontal Machining Center

Product Origin: Taiwan

HHC - CHAIN TYPE TOOL MAGAZINE

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

Patented automatic chain tension adjustment mechanism extends the chain service life.

Product Origin: Taiwan

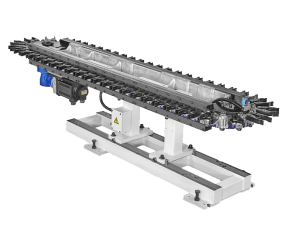

VHC - CHAIN TYPE TOOL MAGAZINE

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. Simple modular tool shifting mechanism with accurate positioning and low failure rate.

2. The use of special cam box in combination with the fully supported tool arm module feature high stability and smoothness.

Product Origin: Taiwan

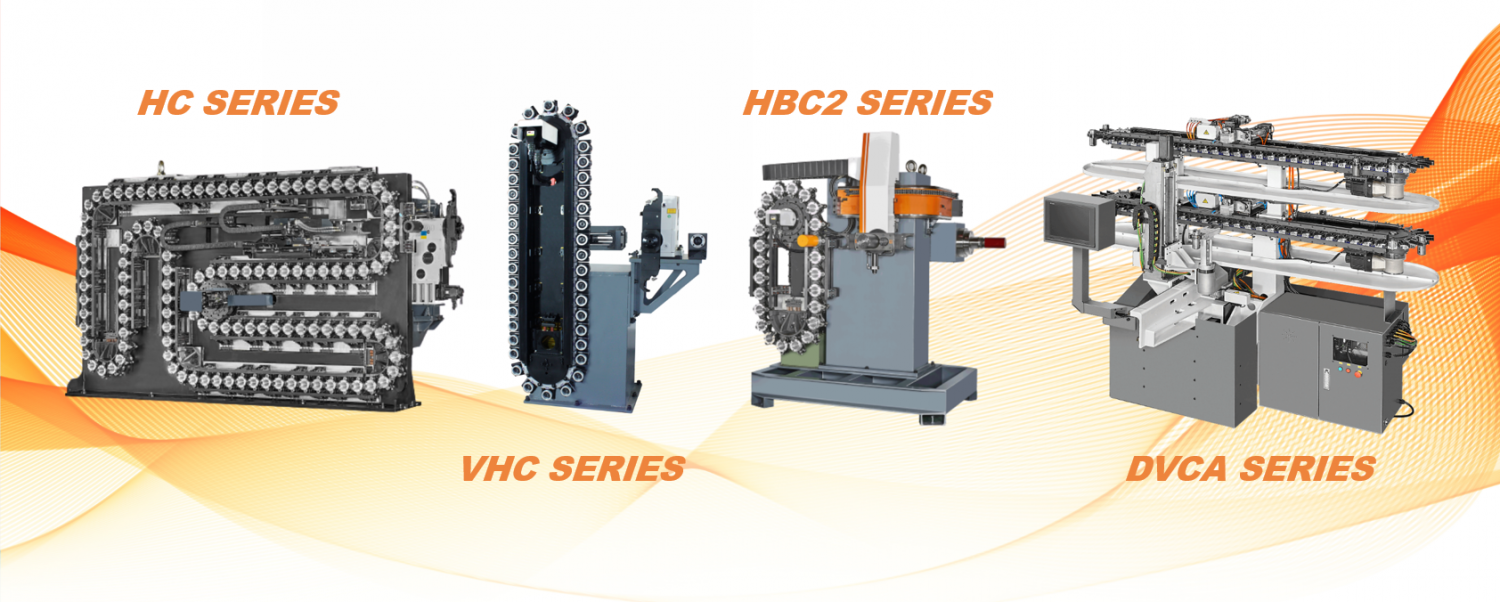

HC - TOOL MAGAZINE WITH HYDRAULIC ROBOTIC ARM

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. A transmission mechanism consisting of servo motor and low backlash speed reducer.

2. Front-mounted transmission mechanism.

3. A modular transmission mechanism consisting of hydraulic motor and positioning hydraulic cylinder.

Product Origin: Taiwan

HC - Chain Type Tool With Hydraulic Rail Robotic Arm

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. Magazine chain operates by rolling, which reduce mechanism resistance, increase life span.

2. Original chain design, detached chain and tool holder structure, easy maintenance.

3. Can be customized with different type of tool holder.

4. Self-complement mechanism-effectivity remove chain chordal action, extend chain life.

Product Origin: Taiwan

HAC - CHAIN TYPE TOOL MAGAZINE

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. The robotic arm features three-position moving motion which increases tool preparation position of tool change and shortens moving time.

2. A transmission mechanism consisting of servo motor and low backlash speed reducer.?

3. A modular transmission mechanism consisting of hydraulic motor and positioning hydraulic cylinder.

Product Origin: Taiwan

HCS - HCSCHAIN TYPE TOOL MAGAZINE

|

For Horizontal Machine

Sanjet International Co. Ltd

Tool changers and magazines

1. The stable tool picking mechanism and tool preparation position mechanism provide a modular coordination for simplest calibration.

2. The use of special cam box in combination with the fully supported tool arm module feature high stability and smoothness.

Product Origin: Taiwan

DCVM - Separate cambox verticle tool magazine

|

Customized Product

Sanjet International Co. Ltd

Tool changers and magazines

1. Original chain design, chain operates by rolling.Resistance and noise reduced significantly.Extend life span.

2. Horizontal?vertical module-Replace traditional complicated structure. Solution to horizontal magazine vertical tool change combination.

3. Iron black oxide tube-Don?t break after long term usage.Tidy tube set up, present delicate technics.

4. Integrate magazine and tool changer.Reduce machine maker installation procedure and work time.

Product Origin: Taiwan

CHA - Horizontal chain type pneumatic arm tool magazine

|

Customized Product

Sanjet International Co. Ltd

Tool changers and magazines

1. Vertical-Horizontal Switching Mechanism.Replace the complex construction from old times.Perfect Solution for Horizontal Magazine requiring Vertical Tool Change.

2. Calibration of Concentricity by Spindle Aligners.High repeatability of positioning.

3. Tool change by Arm.High stability in tool gripping.Space-saving tool change movement

4. Vertical-Horizontal Switching Tool change can be perfectly done by Patented Arm.

Product Origin: Taiwan

TD.TDS PLUS - Tool Magazine Servo Type Tool Magazine

|

For Tapping Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. The tool magazine features low volume, light weight, small tool swing

diameter and convenient maintenance.

2. Fully enclosed tank-type transmission mechanism, extends lifespan

effectively.

3. Connecting any brand of controller by I/O link.

4. High-precision one-piece tool gripper achieves fast assemble and

replacement.

5. End point feedback encoder, intelligent position tracking function.

Product Origin: Taiwan

TDF3 - Servo Type Tool Magazine

|

For Tapping Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. Low volume, light weight and high tool loading capacity.

2. Special floating tool gripper design.

3. End point feedback encoder, smart correction tracking.

4. Connecting any brand of controller by I/O link.

Product Origin: Taiwan

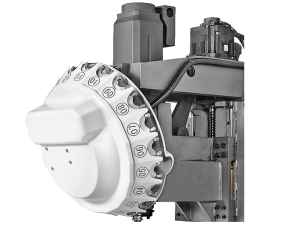

DK - Drum Type Tool Magazine

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. Powder dusts, fine chips or any contaminant may affect the accuracy of tool taper on a conventional tool pocket. However, dust adhering can be reduced by around 80% when using tool pockets in this series.

2. Standardized wiring and the use of connector-type sensor switch make it easy to maintain or replace motion sensors.

3. Completely waterproof design with separate tool seats, easy to change to different tool specifications.

4. Sanjet chooses cam that employs roller cam for tool change with maximum smoothness and stability.

Product Origin: Taiwan

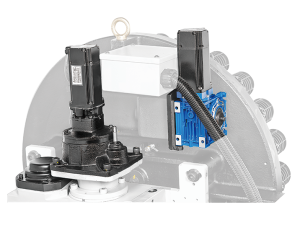

SDK - Tool Magazine With Simple Electronic Brake

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. With electronic braker, motors don't require relay, saves maintenance cost.

2. Motors without brake eliminates lining wearing issue. Lifespan is longer and more stable.

Product Origin: Taiwan

DKCS - SERVO SYSTEM DRUM TYPE TOOL MAGAZINE

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. Unique acceleration and deceleration of the S-curve control, the arm is rotated to the buckle tool, the spindle impact to a minimum, effectively protect the spindle and prolong life.

2. When using a tool with more than 4KG, follow the heavy tool mode instructions to ensure tool change stability.

3. Global Initiative Hand Crank Reducer. Exclusive use of the Sanjet's manual rotating crank for the adjustment of operation mechanism.

DKCS ?

- Single Servo: The magazine motor uses a general motor.

- The driver of I/O communication indicates tool magazine loading capacity and output tool disk position signal with encoding type, and it can be used with any brand of controller and system.

Product Origin: Taiwan

DKSS - SERVO SYSTEM DRUM TYPE TOOL MAGAZINE

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. Unique acceleration and deceleration of the S-curve control, the arm is rotated to the buckle tool, the spindle impact to a minimum, effectively protect the spindle and prolong life.

2. When using a tool with more than 4KG, follow the heavy tool mode instructions to ensure tool change stability.

3. Global Initiative Hand Crank Reducer. Exclusive use of the Sanjet's manual rotating crank for the adjustment of operation mechanism.

DKSS:

- Double Servo: Magazine with servo motors can effectively avoid the inertia force caused by the rotation of the tool disk when machining. It affects the machining accuracy of the column vibration.

- The integration of two single drive servo motor, using I/O communication, can be any brand of controller and system.

Product Origin: Taiwan

SDR - Electric Breaker Type Radial Magazine

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. FEATURE:

Radial set up tool pots saves tool changing time and makes machine compact.Special tool pot set up reduces pot tilting stroke, increases product life. Lower inertia force in tool pot tilting reduces side effect to column, improves machine precision.

2. DETAIL:

heavy Duty Connector

Tidy appearance, convenience installation, similar army connector with easy wiring. Improving installing speed effectively and avoiding mistaken wiring. Improving water proof by water proof pad.

3. EB2:

High/low voltage separated safely. Added tool disk/arm recognition signal. Motor motion output separately. Improving noise prevent, reducing signal disturbance effectively.

Product Origin: Taiwan

DRSS - Servo Type Radial Magazine

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. FEATURE:

Radial set up tool pots saves tool changing time and makes machine compact. Special tool pot set up reduces pot tilting stroke, increases product life. Lower inertia force in tool pot tilting reduces side effect to column, improves machine precision.

2. Double servo motors:

Servo magazine motor avoids vibration caused by magazine rotation during machining, improves machine precision.

3. Global pioneer:

Sanjet patented manual crank reducer provides convenient adjustment.

Product Origin: Taiwan

CV - CHAIN TYPE MAGAZINE

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. The tool magazine is a flattened transmission design that not only eliminates the problem of installation on the machine, but also runs continuously to avoid chain loosening due to intermittent running. In addition, the front-mount chain positioning mechanism ensures high positioning accuracy of the tool pocket.

2. The new and exclusive chain design ensures stability. Moreover, tool pot assembling is easy and fast. Stability and convenient installing and replacing are the top features in the industry.

Product Origin: Taiwan

LV - ARMLESS TYPE TOOL MAGAZINE

|

For Vertical Machining Center

Sanjet International Co. Ltd

Tool changers and magazines

1. The exclusive use of the SANJET ball type indexing mechanism provides machine center smooth and stable tool changing.

2. SANJET unique one-piece constructed tool gripper design provides strong tool holding and prevents deformation of the tool disk.

3. Electric discharge machine dedicated gripper.

Loading ...