SCHIESS

Products

SCHIESS Werkzeugmaschinenfabrik GmbH

Services for mounting machine

Retrofit

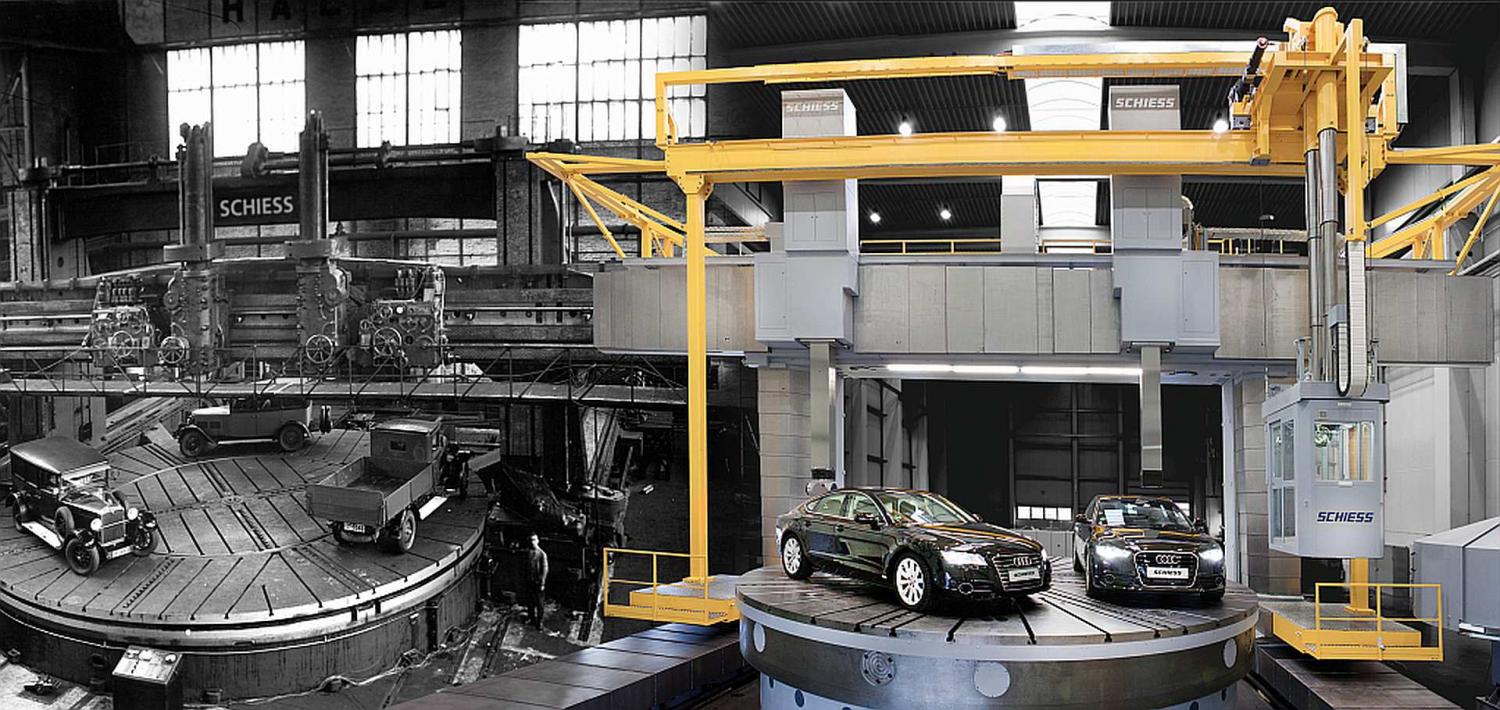

Especially in the segment of XXL machines the area of retrofit and service is a very important field. When buying a new XXL machine, one has to consider the costs for the machine as well as those for the periphery (foundation, media connections, etc.) By having the machine retrofitted, the customer saves this effort and receives a nearly-new machine at a lower cost. Furthermore, this machine suits the existing layout and fulfills all current technical requirements.

Our retrofit is independent of manufacturer and machining processes and involves overhauling of machine tools and components. To facilitate this, not only the Schiess assembly team but also the capacities of Purchasing, Manufacturing, Quality Management, Electrical Commissioning and Documentation are available.

Just-in-time tot he exhibition we’ll finish a comprehensive retrofit of a XXL turning machine. We’ll explain these project on our booth to you.

Our worldwide service is independent of the manufacturer and involves everything including setting up, alignment, commissioning, troubleshooting, test machining and customer specific requests.

In addition to service, we also offer preventive measures to guard against machine failures/downtimes e.g. in the form of service/maintenance contracts.

We show on the EMO the assembly / disassembly as an example for these theme. The object: 2-axis-head of our XXL machines.