Tools for highest expectations!

Better chip control with 3D-lasered chip forming geometries!

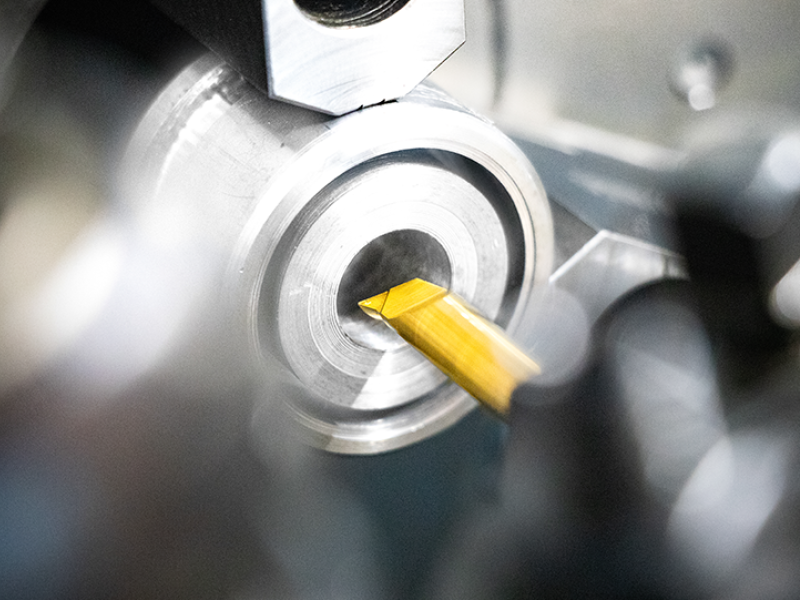

SIMTEK Präzisionswerkzeuge GmbH is presenting its range of tools with 3D-lasered chip forming geometries. According to the manufacturer, lasering the cutting edge geometry can sustainably improve production processes in metalworking and increase process reliability.

"We have been working with our customers for decades to develop optimal tool solutions for specific applications, particularly in precision and micro machining," explains Norbert Seifermann. The CEO of the Mössingen-based precision tool manufacturer SIMTEK played a leading role in the development of the new 3D laser technology.

Years of development work lead to success

SIMTEK has been investing heavily in the research and development of 3D-lasered chip forming geometries since 2018. After five years and numerous tests, the tool specialist was able to produce high-precision 3D-lasered chip forming geometries in series production according to individual customer requirements outside of laboratory conditions. In the meantime, tools with 3D-lasered chip forming geometries have also been implemented in the standard range. In the future, the manufacturer intends to continuously expand its standard range with additional laser geometries. These have proven themselves in practice in various pilot projects over the last two years.

"The introduction of laser geometries marks an enormous advance in tool technology," Norbert Seifermann is certain. Individually designed and 3D-lasered chip forming geometries are the most effective and economical solution for optimum chip control. "Our tools are not only sharper and more precise, they are also able to reliably meet the requirements for chip control." With a view to long tool life and process reliability, this is not only of crucial importance in sectors such as the automotive, aerospace and medical technology industries.

The optimum design of a 3D-lasered chip forming geometry is developed in coordination with the customer, taking into account the component and the respective process parameters (such as cutting speed, feed rate, cutting depth, etc.). Thanks to this, optimum results can be achieved when machining small diameters, running with high cutting speeds with a high heat input, high forming depths or long-chipping materials, for example.

The SIMTEK tool range currently includes over 11.000 standard tools listed in the catalog. In addition, several thousand individual tool concepts are created every year. The development and design expertise is extremely high and ranges from blanks to coating on own systems. Despite the large number of individual tool developments per year, SIMTEK is known for its reliable delivery times. The target delivery reliability is over 98 percent, which is now also to apply to the new 3D-lasered chip forming geometries.

Copyright: SIMTEK AG

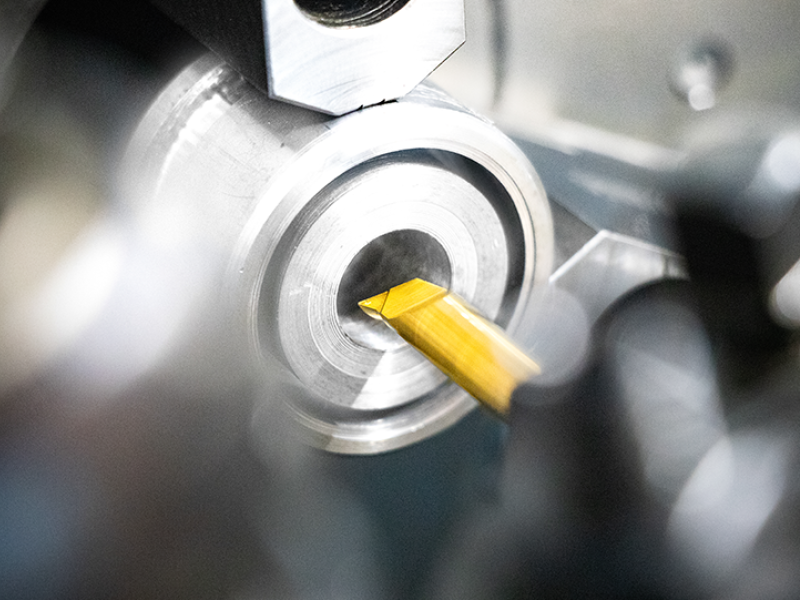

SIMTEK Präzisionswerkzeuge GmbH is presenting its range of tools with 3D-lasered chip forming geometries. According to the manufacturer, lasering the cutting edge geometry can sustainably improve production processes in metalworking and increase process reliability.

"We have been working with our customers for decades to develop optimal tool solutions for specific applications, particularly in precision and micro machining," explains Norbert Seifermann. The CEO of the Mössingen-based precision tool manufacturer SIMTEK played a leading role in the development of the new 3D laser technology.

Years of development work lead to success

SIMTEK has been investing heavily in the research and development of 3D-lasered chip forming geometries since 2018. After five years and numerous tests, the tool specialist was able to produce high-precision 3D-lasered chip forming geometries in series production according to individual customer requirements outside of laboratory conditions. In the meantime, tools with 3D-lasered chip forming geometries have also been implemented in the standard range. In the future, the manufacturer intends to continuously expand its standard range with additional laser geometries. These have proven themselves in practice in various pilot projects over the last two years.

"The introduction of laser geometries marks an enormous advance in tool technology," Norbert Seifermann is certain. Individually designed and 3D-lasered chip forming geometries are the most effective and economical solution for optimum chip control. "Our tools are not only sharper and more precise, they are also able to reliably meet the requirements for chip control." With a view to long tool life and process reliability, this is not only of crucial importance in sectors such as the automotive, aerospace and medical technology industries.

The optimum design of a 3D-lasered chip forming geometry is developed in coordination with the customer, taking into account the component and the respective process parameters (such as cutting speed, feed rate, cutting depth, etc.). Thanks to this, optimum results can be achieved when machining small diameters, running with high cutting speeds with a high heat input, high forming depths or long-chipping materials, for example.

The SIMTEK tool range currently includes over 11.000 standard tools listed in the catalog. In addition, several thousand individual tool concepts are created every year. The development and design expertise is extremely high and ranges from blanks to coating on own systems. Despite the large number of individual tool developments per year, SIMTEK is known for its reliable delivery times. The target delivery reliability is over 98 percent, which is now also to apply to the new 3D-lasered chip forming geometries.

Copyright: SIMTEK AG