Setting new standards

SORALUCE at EMO 2025: Shaping the Future of Machining. Driven by Innovation. Built on Trust.

The manufacturer unveils a new generation of milling machines that are more powerful, more precise, and more intelligent than ever before. These machines are engineered to address the evolving challenges faced by key industries such as aerospace, energy, and mold & die, while anticipating a future that is automated, connected, and data-driven.

At Soraluce, innovation is not an end, it's a way forward. We shape the future of machining by engineering solutions that anticipate industry needs, solve real production challenges, and empower our customers to stay ahead.

Each project is an opportunity to push boundaries together, combining our technological leadership with our clients’ ambition for excellence.

What continues to define Soraluce’s approach, however, goes beyond technology—it is about trust. The company works closely with its customers to adapt solutions to specific processes, challenges, and long-term visions. With every collaboration, it offers more than machines—it offers real commitment.

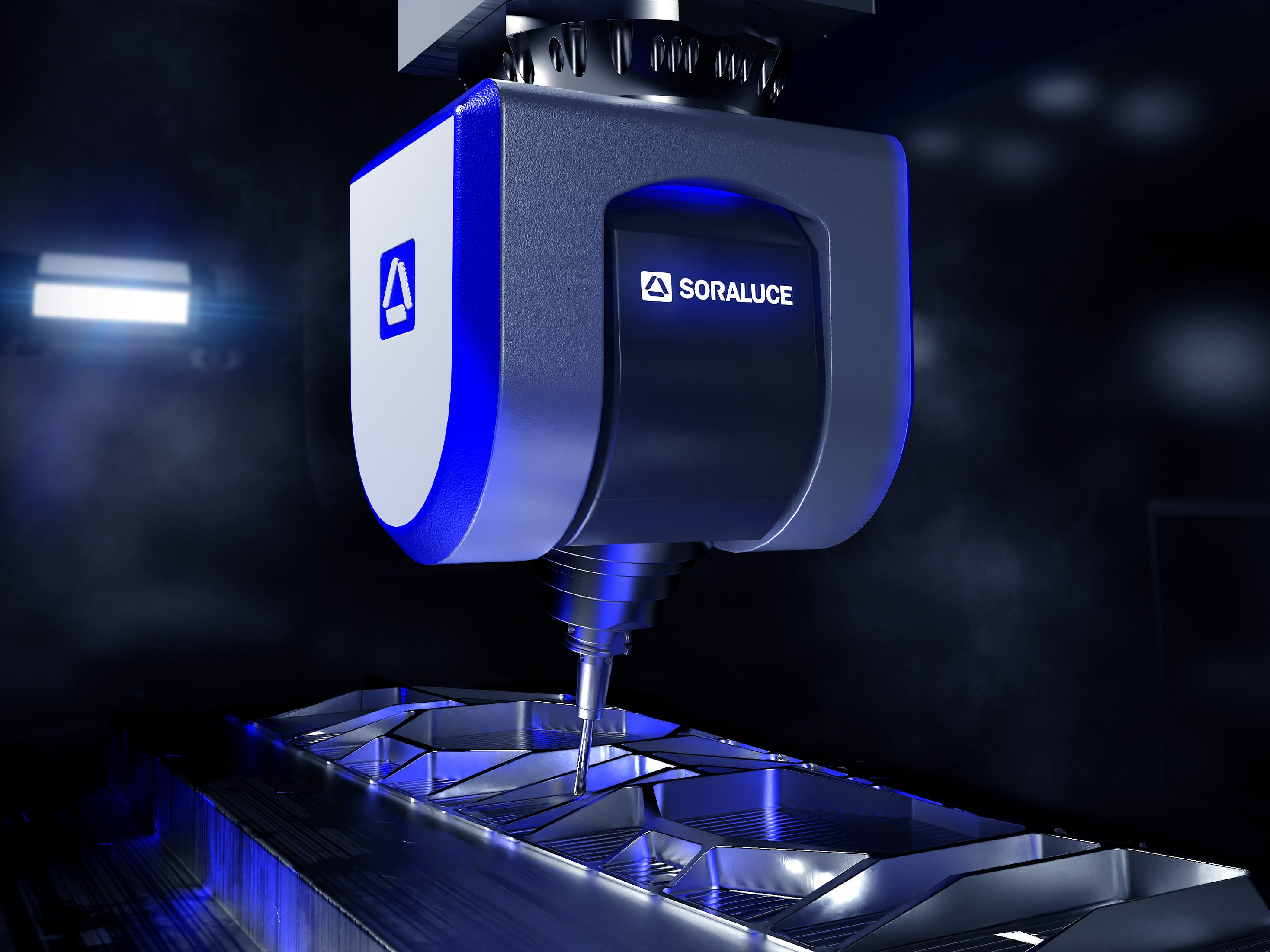

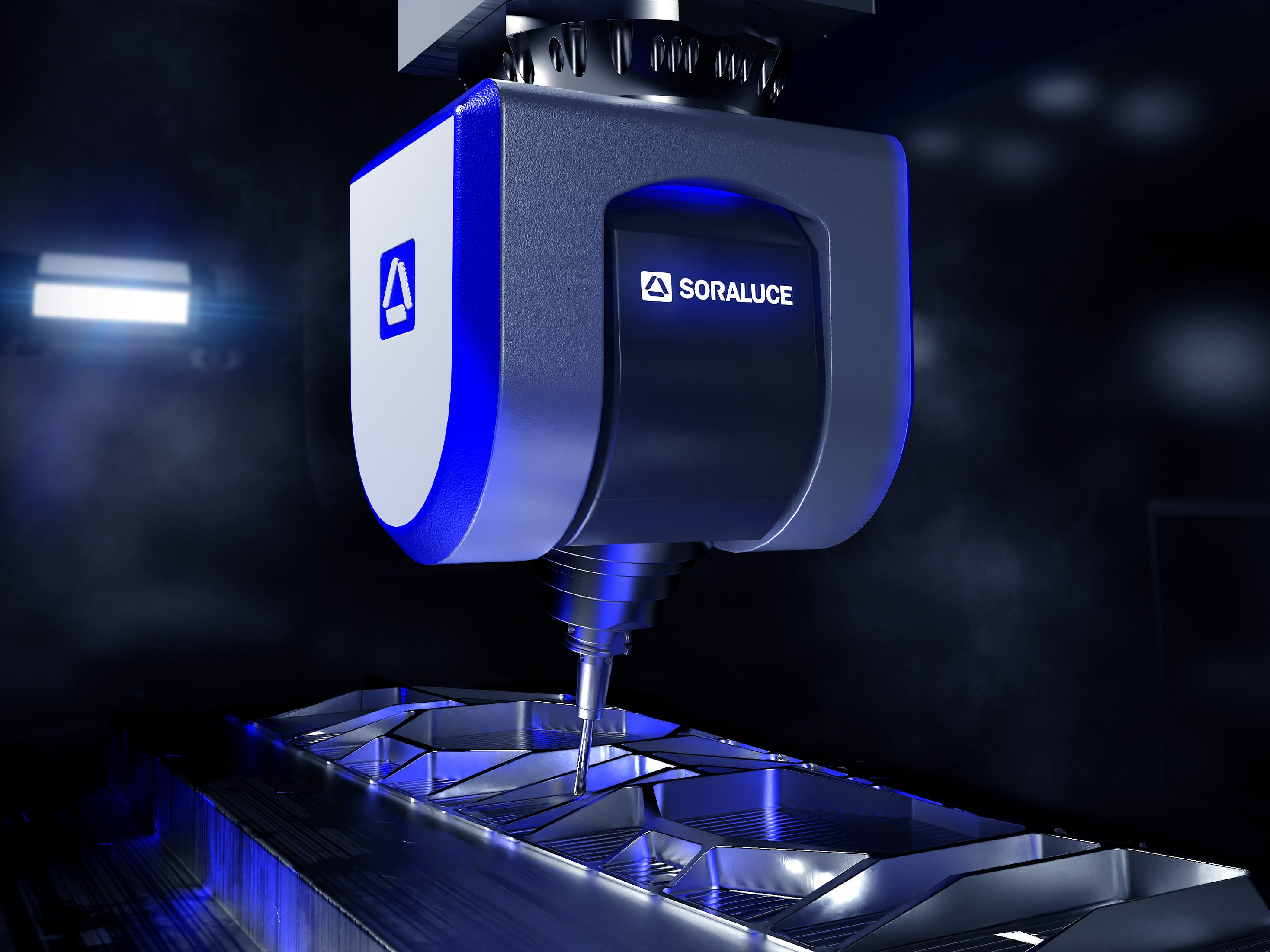

New Dynamic Line High-Rail Gantry Machines

The new High-rail Gantry Machines from Soraluce are engineered to push manufacturing to unprecedented levels of performance. Offering high-speed cutting capabilities, exceptional precision rates, and the ability to handle high-volume machining tasks, these machines are backed by the firm's extensive expertise in the milling sector and state-of-the-art technology.

The Dynamic Line comprises three machine models tailored to applications in sectors such as aerospace, mold & die, and mechanical engineering, with solutions designed specifically for materials like composites, light alloys, and steel-based components.

Customized to meeting unique requirements of diverse industries and applications, these machines can be equipped with either 5-axis contouring fork-type or high-torque milling heads, enabling seamless machining of complex geometries. An advanced splash guarding system ensures a clean and safe work environment, while integrated dust extraction—both within the enclosure and directly at the heads—effectively removes dust and debris generated during operation, maintaining cleanliness and consistent performance.

With outstanding dynamic capabilities, the machines reach axis speeds of up to 60,000 mm/min and acceleration rates of 4 m/s². Their innovative 5-axis heads can achieve spindle speeds of up to 30,000 rpm, enabling rapid, high-precision contouring.

Precision is further supported by thermal stability systems, calibrated kinematics, and advanced high-speed finishing techniques that deliver exceptional surface quality without compromising accuracy.

With powerful milling heads delivering up to 73 kW and 2,000 Nm of torque, and smart damping technologies such as DAS+ and DWS enhancing structural stability, the Dynamic Line ensures reliable, high-performance machining even under the most demanding conditions.

World premiere of the Soraluce Fork-type Head

At the forefront of our EMO showcase is the world premiere of its latest innovation in 5-axis machining: the new Fork-type Head, a next-generation solution designed to set new standards in operational flexibility, precision, and stability.

Engineered for exceptional flexibility and outstanding accuracy on complex geometries, this head integrates seamlessly with the new Dynamic Line of High-Rail Gantry Machines. Developed to meet the rigorous demands of aerospace and mold & die sectors, the Fork-type Head enables precise, stable, and highly efficient machining of intricate contours and hard-to-reach surfaces.

The Fork-type Head features a true 5-axis configuration with direct-drive torque motors, enabling smooth, backlash-free movement and high responsiveness. A fully water-cooled design ensures maximum thermal stability, while high-precision optical encoders offer reliable angular position feedback, ensuring consistent accuracy even during prolonged, high-speed operations. With power output up to 100 kW and spindle speeds up to 30,000 rpm, the head is built for both heavy-duty and high-speed machining. Optional high-frequency electrospindles are available, allowing customization for specific materials and cutting conditions.

Designed for superior mechanical performance and full thermal stability, the new fork-type head expands operational versatility, enabling manufacturers to tackle increasingly intricate parts and demanding materials with complete confidence.

Upgraded Soraluce FP-series

Soraluce is proud to unveil the upgraded version of its flagship FP floor-type milling boring machine, now delivering higher capacity, increased speed, greater power, and unmatched precision. This enhancement optimizes performance and expands customization options to meet the specific needs of each customer.

The Soraluce FP stands out as a productivity powerhouse, combining maximum cutting capacity with exceptional flexibility. Designed to meet the most demanding production requirements, the FP series excels under the highest standards of efficiency, quality, and precision, making it the ideal solution for specialized and highly competitive machining markets.

Thanks to its flexible machine architecture, the FP supports various configurations that facilitate the use of multiple workstations and enable pendulum machining, significantly reducing unproductive downtime.

Key specifications include a generous longitudinal traverse of 8,000 mm, vertical traverse of 3,200 mm, and a now upgraded cross traverse of 1,800 mm. Its inline motorization features direct-drive motors with high torque integrated into the ram, equipped with an advanced cooling system to ensure maximum reliability and precision. Among the most notable innovations is the 60 kW Soraluce motorization at 7,000 rpm. The machine incorporates a universal stepless head ideal for high-precision interpolation machining.

The machine is included with Ram Balance system into the vertical saddle. This closed-loop system continuously monitors and corrects the ram’s geometrical accuracy, straightness, and parallelism during vertical and cross-axis movements. Functioning as an additional CNC axis with its own direct position measurement, Ram Balance significantly enhances overall machine precision, especially when paired with the automatic head changing system.

The automatic head changer enables seamless management of multiple setups, allowing the CNC to compensate for the weight differences among different heads and maintain exceptional machining accuracy across all configurations.

With these advancements, the upgraded Soraluce FP-series sets a new benchmark in milling boring technology—delivering superior performance, flexibility, and precision for the most demanding industrial applications.

Shaping Aerospace Progress

Maximize efficiency, precision, and reliability in aerospace component machining with Soraluce’s advanced technologies in 5-axis machining, multitasking, automation, vibration control, and smart digital monitoring. Our solutions are engineered to meet the highest standards required for critical aerospace parts such as engines, structural assemblies, fuselages, and landing gear.

The manufacturer’s systems are designed to handle the most demanding materials in the industry—including high-strength titanium alloys, Inconel, large aluminum structures, and advanced composites—ensuring dimensional accuracy, excellent surface finish, and process stability. Whether machining intricate aerostructures or critical engine components, Soraluce delivers consistent, high-quality results.

At the core of our offering is 5-axis machining, which enables complex geometries to be produced in a single setup, significantly reducing cycle times while maintaining maximum precision. This versatility allows manufacturers to adapt quickly to diverse materials and industry needs.

To address one of the biggest challenges in machining advanced materials—vibration—Soraluce integrates active damping systems such as DAS+ (Dynamic Active Stabilizer), which detect and suppress vibrations in real time. This technology ensures smoother, safer, and more accurate machining, extending tool life and improving surface quality.

Multitasking capabilities combine milling, turning, drilling, grinding, riveting, and friction welding in a single set-up, minimizing part handling and setup times while reducing errors and costs.

Automation further enhances operational efficiency, ranging from single machines with integrated CNC pallet control to advanced flexible machining cells managed by the firm’s proprietary software solutions. This ensures optimized workflows, higher throughput, and production flexibility.

Complementing these innovations is smart monitoring technology, providing real-time oversight of machining processes to optimize productivity and minimize equipment wear. The system tracks production, enables traceability, logs stoppages, manages tool wear, and integrates with ERP and OEE systems, supporting large-scale manufacturing environments.

Together, these technologies form a comprehensive aerospace machining strategy—delivering superior performance, reduced operational costs, and total process control from the first part through full production runs. Soraluce also offers turnkey projects tailored to each client’s needs, including specialized heads, custom tooling, and validated machining cycles to ensure maximum reliability and productivity from day one.

Smart Automation

Responding to growing demand for efficient, flexible production in complex, multi-reference environments, Soraluce presents its Smart Automated Solutions, developed to optimize productivity and reduce unproductive time across the entire manufacturing process.

Automation at this level goes beyond standard solutions. The firm’s systems are designed to accommodate large-scale components with tailored configurations adaptable to different part types and batch sizes. From single machines with CNC-integrated pallet control to advanced flexible cells coordinated by industrial PCs, every solution is customized for efficiency and real-world application.

The manufacturer’s palletizing systems stand out—engineered around the principles of precision, modularity, and adaptability. These systems streamline workflows, reduce changeover durations, and significantly boost overall plant productivity.

Further enhancing production agility, Soraluce have implemented centralized tool storage systems, operating in full integration with our proprietary tool management software. This interconnected setup enables shared tool access between machines, eliminates selection errors, reduces the need for duplicate tooling, and minimizes the space required for storage infrastructure. All tool automation processes are data-driven—guided by real-time production orders, delivery schedules, and tool availability—ensuring just-in-time manufacturing.

Driving this automation ecosystem is the Control System, a powerful software platform developed in-house by Soraluce Software Factory. Based on the innovative Job List concept, it provides complete integration of all manufacturing flow components: machines, parts, pallets, tools, CNC programs, fixtures, and operations. This unified system orchestrates the entire cell, maximizing productivity while enabling full traceability, process transparency, and seamless operation across every level of the production environment.

About Soraluce

With a wealth of experience based on 60 years of history and inspired by innovation, Soraluce is moving the machine tool sector forward with innovative pioneer engineering solutions that have made it a benchmark within the sector.

Soraluce's success is based on excellent quality, the best possible service, in-house state-of-the-art technology, its technological capacity to customize each product in accordance with the individual requirements of the customer, and a fully international outlook. Soraluce produces innovative solutions with commitment to the technological progress of its customers, addressing the challenges of the most demanding machining work, and establishing new standards.

Soraluce offers an extensive range of milling machines, boring machines and vertical lathes, multipurpose solutions and automated lines and systems, with a professional advisory service in machining engineering and a highly experienced technical team to assess the production and machining processes of our customers and provide solutions to optimize them in accordance with the parameters of quality, efficiency and costs demanded by the investor.

Innovation is Soraluce's cutting edge, and it has pioneered many of the technologies driving the machine tool sector, such as, for example, the DAS™ system (Dynamic Active Stabilizer), the Modular Quill system and the Ram Balance (a system to offset ram fall), all of which have been patented.

This European brand has a wealth of experience and has sold over 3,300 machines, almost half of them in Germany, an extremely demanding market. It has also been observed over the years that 80% of customers have returned to confirm their trust in its products.

Soraluce forms part of Danobatgroup, the machine tool division of the Mondragon Corporation, one of Europe's largest business groups. It has Excellence Centers in Germany, Italy, the USA, China and the UK, and its own R+D center staffed by 120 engineers and 29 Ph.Ds, a facility that goes back more than 30 years. Danobatgroup provides one of the market's most comprehensive and competitive multi-technology offers. With a headcount of 1,460 employees and a turnover of 340 million euros, it has a clear focus on innovation, investing approximately 9% of revenue in R+D+i.

The manufacturer unveils a new generation of milling machines that are more powerful, more precise, and more intelligent than ever before. These machines are engineered to address the evolving challenges faced by key industries such as aerospace, energy, and mold & die, while anticipating a future that is automated, connected, and data-driven.

At Soraluce, innovation is not an end, it's a way forward. We shape the future of machining by engineering solutions that anticipate industry needs, solve real production challenges, and empower our customers to stay ahead.

Each project is an opportunity to push boundaries together, combining our technological leadership with our clients’ ambition for excellence.

What continues to define Soraluce’s approach, however, goes beyond technology—it is about trust. The company works closely with its customers to adapt solutions to specific processes, challenges, and long-term visions. With every collaboration, it offers more than machines—it offers real commitment.

New Dynamic Line High-Rail Gantry Machines

The new High-rail Gantry Machines from Soraluce are engineered to push manufacturing to unprecedented levels of performance. Offering high-speed cutting capabilities, exceptional precision rates, and the ability to handle high-volume machining tasks, these machines are backed by the firm's extensive expertise in the milling sector and state-of-the-art technology.

The Dynamic Line comprises three machine models tailored to applications in sectors such as aerospace, mold & die, and mechanical engineering, with solutions designed specifically for materials like composites, light alloys, and steel-based components.

Customized to meeting unique requirements of diverse industries and applications, these machines can be equipped with either 5-axis contouring fork-type or high-torque milling heads, enabling seamless machining of complex geometries. An advanced splash guarding system ensures a clean and safe work environment, while integrated dust extraction—both within the enclosure and directly at the heads—effectively removes dust and debris generated during operation, maintaining cleanliness and consistent performance.

With outstanding dynamic capabilities, the machines reach axis speeds of up to 60,000 mm/min and acceleration rates of 4 m/s². Their innovative 5-axis heads can achieve spindle speeds of up to 30,000 rpm, enabling rapid, high-precision contouring.

Precision is further supported by thermal stability systems, calibrated kinematics, and advanced high-speed finishing techniques that deliver exceptional surface quality without compromising accuracy.

With powerful milling heads delivering up to 73 kW and 2,000 Nm of torque, and smart damping technologies such as DAS+ and DWS enhancing structural stability, the Dynamic Line ensures reliable, high-performance machining even under the most demanding conditions.

World premiere of the Soraluce Fork-type Head

At the forefront of our EMO showcase is the world premiere of its latest innovation in 5-axis machining: the new Fork-type Head, a next-generation solution designed to set new standards in operational flexibility, precision, and stability.

Engineered for exceptional flexibility and outstanding accuracy on complex geometries, this head integrates seamlessly with the new Dynamic Line of High-Rail Gantry Machines. Developed to meet the rigorous demands of aerospace and mold & die sectors, the Fork-type Head enables precise, stable, and highly efficient machining of intricate contours and hard-to-reach surfaces.

The Fork-type Head features a true 5-axis configuration with direct-drive torque motors, enabling smooth, backlash-free movement and high responsiveness. A fully water-cooled design ensures maximum thermal stability, while high-precision optical encoders offer reliable angular position feedback, ensuring consistent accuracy even during prolonged, high-speed operations. With power output up to 100 kW and spindle speeds up to 30,000 rpm, the head is built for both heavy-duty and high-speed machining. Optional high-frequency electrospindles are available, allowing customization for specific materials and cutting conditions.

Designed for superior mechanical performance and full thermal stability, the new fork-type head expands operational versatility, enabling manufacturers to tackle increasingly intricate parts and demanding materials with complete confidence.

Upgraded Soraluce FP-series

Soraluce is proud to unveil the upgraded version of its flagship FP floor-type milling boring machine, now delivering higher capacity, increased speed, greater power, and unmatched precision. This enhancement optimizes performance and expands customization options to meet the specific needs of each customer.

The Soraluce FP stands out as a productivity powerhouse, combining maximum cutting capacity with exceptional flexibility. Designed to meet the most demanding production requirements, the FP series excels under the highest standards of efficiency, quality, and precision, making it the ideal solution for specialized and highly competitive machining markets.

Thanks to its flexible machine architecture, the FP supports various configurations that facilitate the use of multiple workstations and enable pendulum machining, significantly reducing unproductive downtime.

Key specifications include a generous longitudinal traverse of 8,000 mm, vertical traverse of 3,200 mm, and a now upgraded cross traverse of 1,800 mm. Its inline motorization features direct-drive motors with high torque integrated into the ram, equipped with an advanced cooling system to ensure maximum reliability and precision. Among the most notable innovations is the 60 kW Soraluce motorization at 7,000 rpm. The machine incorporates a universal stepless head ideal for high-precision interpolation machining.

The machine is included with Ram Balance system into the vertical saddle. This closed-loop system continuously monitors and corrects the ram’s geometrical accuracy, straightness, and parallelism during vertical and cross-axis movements. Functioning as an additional CNC axis with its own direct position measurement, Ram Balance significantly enhances overall machine precision, especially when paired with the automatic head changing system.

The automatic head changer enables seamless management of multiple setups, allowing the CNC to compensate for the weight differences among different heads and maintain exceptional machining accuracy across all configurations.

With these advancements, the upgraded Soraluce FP-series sets a new benchmark in milling boring technology—delivering superior performance, flexibility, and precision for the most demanding industrial applications.

Shaping Aerospace Progress

Maximize efficiency, precision, and reliability in aerospace component machining with Soraluce’s advanced technologies in 5-axis machining, multitasking, automation, vibration control, and smart digital monitoring. Our solutions are engineered to meet the highest standards required for critical aerospace parts such as engines, structural assemblies, fuselages, and landing gear.

The manufacturer’s systems are designed to handle the most demanding materials in the industry—including high-strength titanium alloys, Inconel, large aluminum structures, and advanced composites—ensuring dimensional accuracy, excellent surface finish, and process stability. Whether machining intricate aerostructures or critical engine components, Soraluce delivers consistent, high-quality results.

At the core of our offering is 5-axis machining, which enables complex geometries to be produced in a single setup, significantly reducing cycle times while maintaining maximum precision. This versatility allows manufacturers to adapt quickly to diverse materials and industry needs.

To address one of the biggest challenges in machining advanced materials—vibration—Soraluce integrates active damping systems such as DAS+ (Dynamic Active Stabilizer), which detect and suppress vibrations in real time. This technology ensures smoother, safer, and more accurate machining, extending tool life and improving surface quality.

Multitasking capabilities combine milling, turning, drilling, grinding, riveting, and friction welding in a single set-up, minimizing part handling and setup times while reducing errors and costs.

Automation further enhances operational efficiency, ranging from single machines with integrated CNC pallet control to advanced flexible machining cells managed by the firm’s proprietary software solutions. This ensures optimized workflows, higher throughput, and production flexibility.

Complementing these innovations is smart monitoring technology, providing real-time oversight of machining processes to optimize productivity and minimize equipment wear. The system tracks production, enables traceability, logs stoppages, manages tool wear, and integrates with ERP and OEE systems, supporting large-scale manufacturing environments.

Together, these technologies form a comprehensive aerospace machining strategy—delivering superior performance, reduced operational costs, and total process control from the first part through full production runs. Soraluce also offers turnkey projects tailored to each client’s needs, including specialized heads, custom tooling, and validated machining cycles to ensure maximum reliability and productivity from day one.

Smart Automation

Responding to growing demand for efficient, flexible production in complex, multi-reference environments, Soraluce presents its Smart Automated Solutions, developed to optimize productivity and reduce unproductive time across the entire manufacturing process.

Automation at this level goes beyond standard solutions. The firm’s systems are designed to accommodate large-scale components with tailored configurations adaptable to different part types and batch sizes. From single machines with CNC-integrated pallet control to advanced flexible cells coordinated by industrial PCs, every solution is customized for efficiency and real-world application.

The manufacturer’s palletizing systems stand out—engineered around the principles of precision, modularity, and adaptability. These systems streamline workflows, reduce changeover durations, and significantly boost overall plant productivity.

Further enhancing production agility, Soraluce have implemented centralized tool storage systems, operating in full integration with our proprietary tool management software. This interconnected setup enables shared tool access between machines, eliminates selection errors, reduces the need for duplicate tooling, and minimizes the space required for storage infrastructure. All tool automation processes are data-driven—guided by real-time production orders, delivery schedules, and tool availability—ensuring just-in-time manufacturing.

Driving this automation ecosystem is the Control System, a powerful software platform developed in-house by Soraluce Software Factory. Based on the innovative Job List concept, it provides complete integration of all manufacturing flow components: machines, parts, pallets, tools, CNC programs, fixtures, and operations. This unified system orchestrates the entire cell, maximizing productivity while enabling full traceability, process transparency, and seamless operation across every level of the production environment.

About Soraluce

With a wealth of experience based on 60 years of history and inspired by innovation, Soraluce is moving the machine tool sector forward with innovative pioneer engineering solutions that have made it a benchmark within the sector.

Soraluce's success is based on excellent quality, the best possible service, in-house state-of-the-art technology, its technological capacity to customize each product in accordance with the individual requirements of the customer, and a fully international outlook. Soraluce produces innovative solutions with commitment to the technological progress of its customers, addressing the challenges of the most demanding machining work, and establishing new standards.

Soraluce offers an extensive range of milling machines, boring machines and vertical lathes, multipurpose solutions and automated lines and systems, with a professional advisory service in machining engineering and a highly experienced technical team to assess the production and machining processes of our customers and provide solutions to optimize them in accordance with the parameters of quality, efficiency and costs demanded by the investor.

Innovation is Soraluce's cutting edge, and it has pioneered many of the technologies driving the machine tool sector, such as, for example, the DAS™ system (Dynamic Active Stabilizer), the Modular Quill system and the Ram Balance (a system to offset ram fall), all of which have been patented.

This European brand has a wealth of experience and has sold over 3,300 machines, almost half of them in Germany, an extremely demanding market. It has also been observed over the years that 80% of customers have returned to confirm their trust in its products.

Soraluce forms part of Danobatgroup, the machine tool division of the Mondragon Corporation, one of Europe's largest business groups. It has Excellence Centers in Germany, Italy, the USA, China and the UK, and its own R+D center staffed by 120 engineers and 29 Ph.Ds, a facility that goes back more than 30 years. Danobatgroup provides one of the market's most comprehensive and competitive multi-technology offers. With a headcount of 1,460 employees and a turnover of 340 million euros, it has a clear focus on innovation, investing approximately 9% of revenue in R+D+i.