Starrag Group

Products

Machining centres

Five-axis milling machining centres

Bumotec s100 multi

|

Five-axis-machining centre

Starrag Vuadens SA

Five-axis milling machining centres

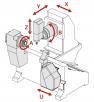

Thanks to linear motors in all axes, the recently developed machine concept of the Bumotec s100 multi machining center accelerates and cuts extremely fast (minimum chip-to-chip time: 500 ms) These enormous performances are also due to a high-speed spindle (60,000 rpm). Four workstations, equipped with a large tool capacity, and two milling spindles work simultaneously.

Thanks to its low footprint and multiple tool magazines (up to 144 tools), the dynamic transfer center is ideal for manufacturers producing ultra-precise components for clocks, computers and electronic applications made from brass, aluminium or stainless steel - very fast and in batch sizes from one to bulk production runs. This makes the machine ideally suited for components up to a size of 80 x 80 x 80 mm.

Bumotec S191 V

|

Five-axis-machining centre

Starrag Vuadens SA

Five-axis milling machining centres

With the CNC Bumotec S191 V turn-mill center, precise and complex components can be produced via 5-axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel.

Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warm-up cycles when starting or after machining interruptions.

Starrag LX Series

|

Five-axis-machining centre

Starrag AG

Five-axis milling machining centres

The LX series was specifically designed for the high-precision, efficient five-axis machining of turbine blades. This ultra-modern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our in-house expertise in the prototype and series production of turbine blades.

Starrag NB Series

|

Five-axis-machining centre

Starrag AG

Five-axis milling machining centres

No matter if it is called a «Blisk» (bladed disk) or an «IBR» (integrally bladed rotor), no matter if it is single stage or multi stage, Starrag?s dedicated machine concept of the NB series provides the best solution for efficiently machining these parts. Blisks made from Titanium, Nickel-based superalloys and the Blisks made of blade steels for stationary gas turbines triggered the development of the NB series. For all the necessary manufacturing operations Starrag provides the benchmark: Efficient roughing for Blisks machined from solid, adaptive machining for friction welded Blisks, high dynamic finishing of the airfoils in point contact. Shortest cycle times and zero scrap rate production are achievable on the Starrag NB series.

Starrag STC Series

|

Five-axis-machining centre

Starrag AG

Five-axis milling machining centres

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multi-blades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

High speed machining centres

Bumotec s191 Linear

|

High speed machining centre

Starrag Vuadens SA

High speed machining centres

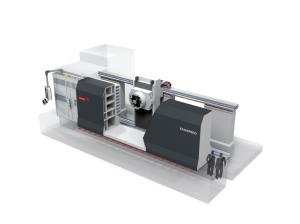

The machines of the S191 series are suitable for turning, milling and grinding of individual parts or from bar (diameters: 32, 50 and 65 mm) in a single setting. The series has an extremely versatile modular structure, which means that it is possible to build any kind of machines from standardised modules for various machining tasks ? including a machining center with seven axes and three spindles.

The CNC Bumotec S191 Linear turnmill center is suitable for complete machining of very complex six sided parts. Linear motors ensure maximum precision and reliable repeatability in the machining of parts. Thanks to the combination of the rapid linear drive with a high-resolution Renishaw measurement system and a stabilised cooling circuit for all heat-generating elements, the S191 Linear achieves excellent productivity. A unique feature is the high-speed spindle (150,000 rpm), on which ceramic parts can also be dry-ground.

Droop+Rein FOGS/FOGS D40

|

high speed machining centre

Starrag AG

High speed machining centres

With its innovative machining technology, the FOGS high speed machining center provides a new dimension in high speed milling. The Droop+Rein concept is a quantum leap in technological development, reducing machining time and increasing quality. The amount of manual finishing work traditionally associated with mould and die machining can be reduced to a minimum. Superior surface finish and accuracy is achieved by the use of efficient cutting strategies. The optional motor spindle changer ensures the optimal performance is always available, whatever the cutting conditions.

The FOGS D40 expands the machine concept to provide a highly economical, versatile machining solution for a wide range of applications. The integrated Droop+Rein D40 ram unit with its integral C-axis, provides a stable and powerful platform for a wide range of milling heads, from conventional vertical spindles, fixed angle heads, two axis positioning and full 5-axis contouring heads.

ECOLINER

|

High speed machining centre

Starrag Technology GmbH

High speed machining centres

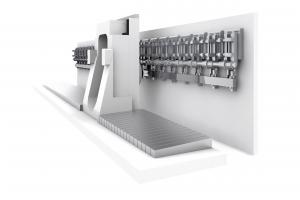

This high-speed machining center for long aluminium stringer components combines the advantages of Sprint-Z3 technology with rapidity and accuracy to provide efficient work piece machining with optimised workpiece handing. The machine is specially designed for machining aluminium profiles (or stringers) of up to 30 metres in length. Thanks to the excellent precision and speed the ECOLINER user can achieve high cutting rates (average machining time of 12 minutes per linear meter), optimum accuracy and excellent surface quality, even with extremely long stringers.

ECOSPEED

|

High speed machining centre

Starrag Technology GmbH

High speed machining centres

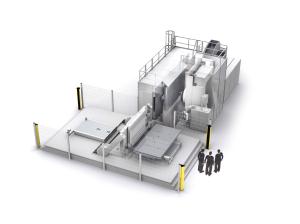

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for high-speed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5-axis simultaneous machining process.

At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

ECOSPEED F

|

High speed machining centre

Starrag Technology GmbH

High speed machining centres

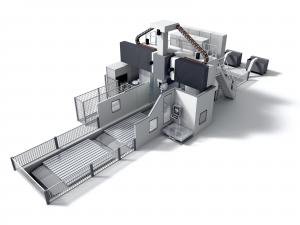

Scharmann has developed the ECOSPEED F for high-speed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED.

What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the X-axis, which enables component loading and unloading during the machining cycle.

ECOSPEED F HT2

|

High speed machining centre

Starrag Technology GmbH

High speed machining centres

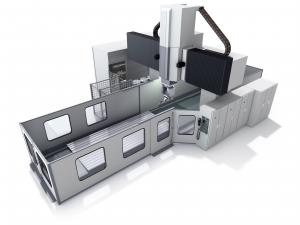

This high-speed machining center is perfect for rapid cutting of small and mediumsized workpieces with maximum productivity. The critical innovation is the Sprint Z3 parallel kinematic machining head, which enables components to be produced with excellent dynamics and precision and an outstanding surface quality, at batch sizes of a single unit through to bulk production. The excellent machining and surface quality means that there is no need for the manual rework that is usually required with conventional machining centers. This results in increased efficiency, improved process reliability and long-term stability. The key features include 1,000 x 1,000 mm pallet size, up to 120 kW spindle power and rapid tool change, from either a chain or rack magazine.

The table with the work piece moves horizontally in the X-axis while the headstock traverses on the stationary column to provide Y-axis movement. Z-axis, A-axis and B-axis movement is provided by the Sprint Z3 head with an additional positioning axis provided by the rotary table.

Horizontal machining centres

Bumotec S1000 C

|

Horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

The Bumotec S1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes.

The machine is configured with seven 4-axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight station comprises a 4-axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3-axis, 3 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates.

Heckert Athletic Series

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

Large machining center are ideal for rapid, cost-effective, complete machining of large and heavy workpieces (swing diameter up to 3,300 mm, maximum weight: 13,000 kg). The modular design provides maximum flexibility and allows tailored production solutions to be created. The center deliver high precision, process optimised and energy efficient machining of housings and prismatic workpieces, primarily in the agricultural machinery and the motor industry, equipment manufacture, pump and compressor production and the wind energy sector.

These Horizontal machining center are based on a very extensive modular concept. The modular design includes the major components, the tool and workpiece handling units, the design of the working spindles, with modified power and speed configurations, and the control options.

Heckert DBF 1000 / 1250

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

The DBF 1000 / 1250 enable complete machining in one clamping position, hence the name DBF (which stands for turning-drilling-milling in German) which has a decisive effect on the productivity of the overall production system. The working spindle of the DBF heads carries out all the machining on the tool that is attached. When turning is required on a clamped work piece, the rotating lathe tool can be radially shifted by ± 35 mm (servo-axis).

Balancing weights integrated in the head compensate for the imbalance set off by the balanced tools, which means that up to 1,200 rpm is possible for turning work.

For boring and milling, a 35/45 kW spindle achieves speeds of up to 3,500 rpm. The DBF 1000 / 1250 enables complete machining with a consistent axial and radial run-out of 5 - 6 µm on the part, which reduces the time and other effort required for clasping, temporary storage and new setting-up each time.

Heckert DBF 630 / 800

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

The DBF 630 / 800 enable complete machining in one clamping position, hence the name DBF (which stands for turning-drilling-milling in German) which has a decisive effect on the productivity of the overall production system. The working spindle of the DBF heads carries out all the machining on the tool that is attached. When turning is required on a clamped work piece, the rotating lathe tool can be radially shifted by ± 35 mm (servo-axis).

The HEC 630/800 Athletic machining centers are the base system concept. The DBF head enables complete machining with a consistent axial and radial run-out of 5-6 µm on the part. The imbalance of the valve plate is compensated by a counterweight, allowing turning speeds up to 1200 r.p.m.

SIP 7000

|

Ultra precise horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

Ever since it was founded in 1862, the Geneva-based Société d?Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models.

SIP 7000/7 (4 and 5 axis)

The horizontal SIP machining centers are living proof that ultra-precision is by no means a myth. Gearbox housings, spindle heads and two-axis turntables can be machined with significantly higher levels of precision than with conventional machining centers, making them the obvious choice for customers.

SIP SPC

|

Horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

he SIP SPC Series not only provides the user with the ultimate in precision but also with tried and tested sophisticated automation. Investment in SIP technology produces returns, thanks to above-average long-term precision and many years of durability.

Universal machining centres

Droop+Rein G/GF

|

portal machining center in gantry design

Starrag Technology GmbH

Universal machining centres

The advantage of machining large, heavy and unwieldy components on a gantry type machine is that the component mass has no effect on the machining process. Droop+Rein created the G/GF series for just such difficult tasks. The gantry machines reliably prevent dynamic loss when supporting and accelerating these high loads. To cope with its demanding machining tasks, the G/GF series boasts many technical highlights, for example, hydrostatic guides on all the linear axes, the thermo-symmetrical construction of the ram-type milling unit and the integral C-axis. Automatic milling head, spindle and tool changing are available by the integration of standard, well proven, expansion modules.

Droop+Rein T/TF

|

portal machining center

Starrag Technology GmbH

Universal machining centres

With its T/TF portal machining center series Droop+Rein supply heavy duty cutting applications for many industries. The range extends from tool making and mould and die, aircraft component production, engine manufacture and through to general engineering applications. Based on stable, extremely accurate and high performance base machines, the T/TF series offers a very comprehensive system for innovative automation. With the addition of various expansion modules the T/TF range can be adapted very easily to any machining task.

Optional automatic milling head, spindle and tool changing units enable complex and demanding machining routines to be performed. Due to Droop+Rein?s extensive applications expertise a wide variety of different milling heads are available, vertical heads, angled heads as well as fork-type milling heads for positionable or simultaneously controlled applications.

Droop+Rein TFS

|

portal machining center

Starrag Technology GmbH

Universal machining centres

For machine manfacturers and toolmakers, flexibility, cost effectiveness and precision play a very important role, especially when machining large components. These three requirements are what led to the development of the TFS portal machining center with its fixed cross-rail. Customers use the modular principle to select the table configuration, control systems and milling units appropriate to their individual tasks. The flexible D40 ram-type milling unit with its integral C-axis, provides a stable platform for our wide range of milling heads, from a conventional vertical spindle through fixed angle heads and on to 3+2 axis and full 5-axis contouring.

The large number of well proven, automatically exchangeable milling heads increases the range of suitable applications. The TFS range of attachments also includes automatic spindle changing as well as tool and component measurement.

Vertical machining centres

SIP 5000

|

Ultra precise vertical machining centre

Starrag Vuadens SA

Vertical machining centres

Ever since it was founded in 1862, the Geneva-based Société d?Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models.

SIP 5000/6 / 5000/7

The SIP vertical range is a must for all producers of parts with high levels of value creations. It enables ultraprecision positioning and the closest of dimensional tolerances for drilling and milled surfaces.