The main theme of this year's Open House was "Focus on 4.0". The roughly 600 guests from die, mold and model manufacturing as well as from industrial design and mechanical engineering had the opportunity to learn about three different 4.0 topics in presentations and at many stands: Tebis 4.0, Proleis 4.0 and Industry 4.0.

Presentation program with keynote on Industry 4.0

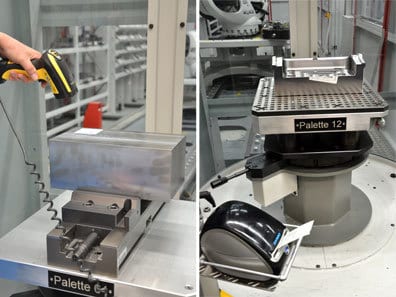

Josef-Peter Gallenberger, Head of BMW Group Die Manufacturing in Munich and Dingolfing, reported on Industry 4.0 (fourth industrial revolution) manufacturing in practice. In die manufacturing in the BMW Group – classic individual part manufacturing – "intelligent components" as the basis for automated Industry 4.0 manufacturing are no longer a vision but are already a part of everyday life. In this process established using software components from Tebis and ID Proleis, 10,000 small parts such as trim steels and flanging plates are now manufactured every year in a highly automated process in a manufacturing cell.

The relationship to Industry 4.0: The digital model of the component is enriched with increasingly more data on its own manufacturing over the course of the process. The actual component is identified by a barcode stamp and is synchronized online with the virtual component. Therefore, it has all the information from digital planning and NC manufacturing. This data can be called up with a barcode scanner at any time in the real manufacturing world – by both human operators and by the networked systems and machines.

At the well-attended presentations, other Tebis users reported on the benefits Tebis has for them. For example, Hans Brandner, managing director of BBG GmbH & Co. KG, focused on the good results achieved through implementing Tebis structuring measures. In the FMF/WWF Group, the innovative active surface process in Tebis means significantly less reworking on the dies. This was convincingly presented by Jürgen Müller, group technical director.

Marcel Voigt, Manager of CNC Production & Programming in Toyota Motorsport Cologne, presented to the attendees the clear benefits of process structuring with Tebis for his company: The same number of employees completes more orders with less overtime, and the hourly machine cost has gone down significantly. And Kaspar Hürlimann, managing director of the Swiss company Formbar AG, presented information on 40% increased sales and doubled machine runtimes with the same personnel – all thanks to process optimization and automation with Tebis.

In the Process Café, our experts from Consulting and implementation spoke in a relaxed atmosphere about how value creation strategies and technical process chains in manufacturing can be optimized – many qualities are open to you with Tebis as the process supplier.

Tebis 4.0

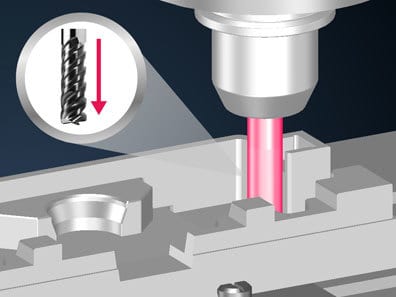

An additional focal point of the event was provided by the functional highlights of Tebis Version 4.0 Release 2: These include adaptive roughing for large depths of cut with full-width avoidance, the creation of guide curves for an optimal path layout, 2.5D machining with standard and free-form features as well as surface optimization at the click of a button. Visitors had the opportunity to see firsthand how Tebis 4.0 can be used to save up to 60% machining time, finish smoother and prepare geometries faster and with greater automation.

Designing processes with Proleis 4.0

Our guests had the opportunity to follow a manufacturing process in our showroom. Process stations demonstrated all the steps from data entry, programming, setup and tool assembly to processing on the machine. We used the Proleis 4.0 software from our collaborative partner ID GmbH to plan and control this manufacturing process and to manage all associated data. This ensures that all information and data are available centrally and transparently, from planning milestones and resources and the procurement of raw materials, to machine and operating data acquisition.

One process station also demonstrated robot tool and pallet handling. Tobias Maresch, robot machining project engineer at KUKA Industries in Augsburg, explained the benefits and opportunities offered by robot-based machining and presented both standard solutions as well as specific customer solutions in his presentation. For example, specially-equipped robot systems can be used to combine the machining process with handling or quality assurance.

Tebis offers extensive software for planning, controlling and managing data in combination with the Proleis 4.0 software from ID GmbH. Our guests at the Tebis Open House were invited to experience the world premiere of the new Proleis Version 4.0. They had the opportunity to test the new Proleis functions for themselves: Information terminals distributed around the facility provided an electronic management system based on Proleis A touch screen provided visitors with information on the locations and contents of the stands. Webcams provided live images of current activities at the stands and in the presentations. The experts from both companies demonstrated the benefits and opportunities offered by Industry 4.0 for die and mold manufacturing: These include the networking of internal systems and technology as well as industrial manufacturing with intelligent components. Tebis makes the components intelligent because the software knows the manufacturing environment and the manufacturing processes it represents, so that the components "know" how they are produced. At the same time, Proleis knows all the planning data and capacities, with the result that the combination of Tebis and Proleis yields a highly flexible, complete digitally controlled manufacturing with transparent information flow – all characteristics of Industry 4.0.

Germany

Germany