ADVANCING EUROPE'S MACHINERY INDUSTRY

Barmag's new texturing machine impresses the market

eFK EvoSmart sets new standards in efficiency and productivity

Barmag's new texturing machine impresses the market

Remscheid, 08. January 2026 – Since its premiere at ITMA Asia + CITME 2025, the eFK EvoSmart texturing machine has achieved impressive market success. The innovative technology is winning over yarn manufacturers worldwide who are committed to energy-efficient and economical production processes. A total of 84 machines has already been sold – including in China, Turkey, and Indonesia – a clear sign of the industry's confidence in this forward-looking solution.

"Energy efficiency and top quality are key factors for successful yarn production," explains Dr. Wolfgang Ernst, Head of Sales at Barmag. "With the eFK EvoSmart, we are setting new standards in this area: intelligent technologies and significantly reduced maintenance requirements enable our customers to achieve future-proof production that takes quality and cost-effectiveness to a new level," he continues.

eFK EvoSmart – Efficiency and qualityThe market response to the eFK EvoSmart clearly shows how great the interest of yarn producers is in energy-optimized and maintenance-friendly solutions. The combination of the innovative EvoHeater heating technology and the single-converter-controlled Smart Godets is particularly impressive: it enables a significant reduction in energy consumption – with potential savings of 25% per kilogram of yarn.

With its innovative EvoHeater design, which simplifies the previously time-consuming task of heater cleaning and, despite the heater being closed, makes handling much easier for operating personnel and doubles maintenance intervals, the eFK EvoSmart sets new standards. The result: up to 50% less maintenance, higher plant availability, and increased productivity - a clear competitive advantage. Whether in weaving, knitting, or finishing, the consistent performance of the eFK EvoSmart ensures smooth processes and the best results in further processing.

"With the eFK EvoSmart, we offer our customers a solution that sustainably reduces their operating costs while meeting future efficiency requirements with consistently high yarn quality," summarizes Wolfgang Ernst.

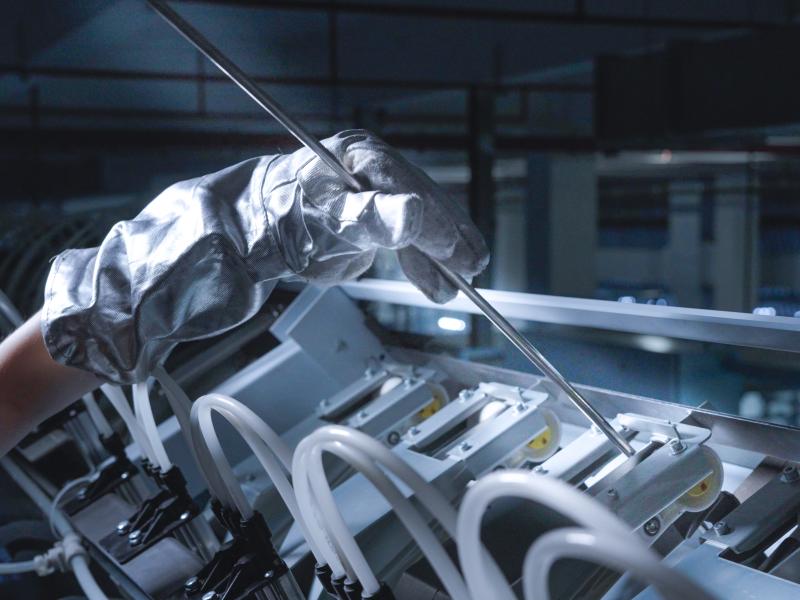

Caption 1:

The eFK EvoSmart’s new EvoHeater technology with patented heater design guarantees the highest yarn quality with up to 45% energy savings, which has a direct impact on operating costs.

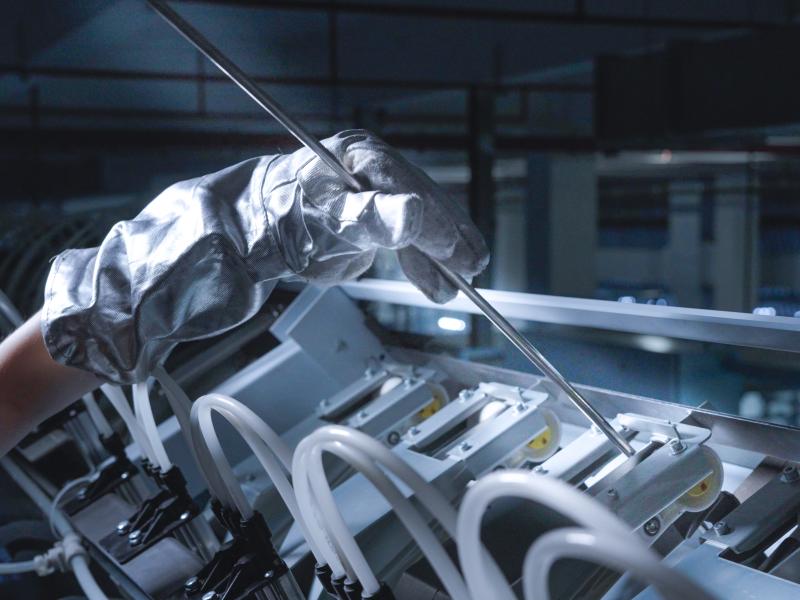

Caption 2:

Smart Godets – the new technology of single-converter-controlled godets optimizes the operating point of each godet, thereby significantly improving energy consumption.

>> picture download

About Barmag

Since 2025, the Swiss Oerlikon Group has been operating its manmade fibers business as a subsidiary under the traditional name Barmag. This includes the established product brands Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven. As a future-oriented company, the research and development of Barmag is driven by energy-efficiency and sustainable technologies (e-save).

Barmag is one of the leading providers of manmade fibers filament spinning systems, texturing machines, BCF systems, staple fibers systems and solutions for the production of nonwovens. Together with its range of polycondensation and extrusion systems and their key components, Barmag caters to the entire manufacturing process – from the monomer all the way through to the textured yarn – and supports it with customer-oriented engineering services. The product portfolio is rounded off with automation and digital solutions. In addition, Barmag offers high-precision gear metering pumps for the textile industry and other sectors, including the automotive, chemical and paint industries.

The main markets for the Barmag product portfolio are in Asia, particularly in China, India, Türkiye and the USA. Worldwide, Barmag – with round about 2,500 employees – has a presence in 120 countries with production, sales and distribution and service organizations. At the Research and Development centers in Remscheid, Neumünster (Germany), and Suzhou (China), highly qualified engineers, technologists and technicians develop innovative and technologically leading products for tomorrow’s world.

Oerlikon (SIX: OERL) is a global leader in surface technologies. Headquartered in Pfäffikon, Switzerland, the Group has a global presence with over 12 000 employees across 199 locations in 38 countries, achieving sales of CHF 2.4 billion in 2024.

For further information, please visit: www.barmag.com

Contact:

André Wissenberg

Marketing, Corporate Communications

& Public Affairs

Tel. +49 2191 67 2331

Fax +49 2191 67 1313

[email protected]

Ute Watermann

Marketing, Corporate Communications

& Public Affairs

Tel. +49 2191 67 1634

Fax +49 2191 67 1313

[email protected]

eFK EvoSmart sets new standards in efficiency and productivity

Barmag's new texturing machine impresses the market

Remscheid, 08. January 2026 – Since its premiere at ITMA Asia + CITME 2025, the eFK EvoSmart texturing machine has achieved impressive market success. The innovative technology is winning over yarn manufacturers worldwide who are committed to energy-efficient and economical production processes. A total of 84 machines has already been sold – including in China, Turkey, and Indonesia – a clear sign of the industry's confidence in this forward-looking solution.

"Energy efficiency and top quality are key factors for successful yarn production," explains Dr. Wolfgang Ernst, Head of Sales at Barmag. "With the eFK EvoSmart, we are setting new standards in this area: intelligent technologies and significantly reduced maintenance requirements enable our customers to achieve future-proof production that takes quality and cost-effectiveness to a new level," he continues.

eFK EvoSmart – Efficiency and qualityThe market response to the eFK EvoSmart clearly shows how great the interest of yarn producers is in energy-optimized and maintenance-friendly solutions. The combination of the innovative EvoHeater heating technology and the single-converter-controlled Smart Godets is particularly impressive: it enables a significant reduction in energy consumption – with potential savings of 25% per kilogram of yarn.

With its innovative EvoHeater design, which simplifies the previously time-consuming task of heater cleaning and, despite the heater being closed, makes handling much easier for operating personnel and doubles maintenance intervals, the eFK EvoSmart sets new standards. The result: up to 50% less maintenance, higher plant availability, and increased productivity - a clear competitive advantage. Whether in weaving, knitting, or finishing, the consistent performance of the eFK EvoSmart ensures smooth processes and the best results in further processing.

"With the eFK EvoSmart, we offer our customers a solution that sustainably reduces their operating costs while meeting future efficiency requirements with consistently high yarn quality," summarizes Wolfgang Ernst.

Caption 1:

The eFK EvoSmart’s new EvoHeater technology with patented heater design guarantees the highest yarn quality with up to 45% energy savings, which has a direct impact on operating costs.

Caption 2:

Smart Godets – the new technology of single-converter-controlled godets optimizes the operating point of each godet, thereby significantly improving energy consumption.

>> picture download

About Barmag

Since 2025, the Swiss Oerlikon Group has been operating its manmade fibers business as a subsidiary under the traditional name Barmag. This includes the established product brands Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven. As a future-oriented company, the research and development of Barmag is driven by energy-efficiency and sustainable technologies (e-save).

Barmag is one of the leading providers of manmade fibers filament spinning systems, texturing machines, BCF systems, staple fibers systems and solutions for the production of nonwovens. Together with its range of polycondensation and extrusion systems and their key components, Barmag caters to the entire manufacturing process – from the monomer all the way through to the textured yarn – and supports it with customer-oriented engineering services. The product portfolio is rounded off with automation and digital solutions. In addition, Barmag offers high-precision gear metering pumps for the textile industry and other sectors, including the automotive, chemical and paint industries.

The main markets for the Barmag product portfolio are in Asia, particularly in China, India, Türkiye and the USA. Worldwide, Barmag – with round about 2,500 employees – has a presence in 120 countries with production, sales and distribution and service organizations. At the Research and Development centers in Remscheid, Neumünster (Germany), and Suzhou (China), highly qualified engineers, technologists and technicians develop innovative and technologically leading products for tomorrow’s world.

Oerlikon (SIX: OERL) is a global leader in surface technologies. Headquartered in Pfäffikon, Switzerland, the Group has a global presence with over 12 000 employees across 199 locations in 38 countries, achieving sales of CHF 2.4 billion in 2024.

For further information, please visit: www.barmag.com

Contact:

André Wissenberg

Marketing, Corporate Communications

& Public Affairs

Tel. +49 2191 67 2331

Fax +49 2191 67 1313

[email protected]

Ute Watermann

Marketing, Corporate Communications

& Public Affairs

Tel. +49 2191 67 1634

Fax +49 2191 67 1313

[email protected]