Real and virtual worlds in harmony?

Production processes are coming up against their virtual limits - Industry 4.0: process and machine simulation are trending

Frankfurt am Main, 25 February 2014. – The vision of Industry 4.0 is taking on ever-more-tangible shape. But before it becomes reality, the task is to bring the real world of production equipment into harmony with its virtual representatives. For this purpose, virtual control of the machine tools and process simulation have to reflect everyday shopfloor reality. The obstacles still to be overcome are analysed by Dr.-Ing. Werner Herfs MBA from the Machine Tool Laboratory at RWTH University in Aachen.

Dr. Herfs, as an electrical engineer, what’s your assessment of the virtual situation?

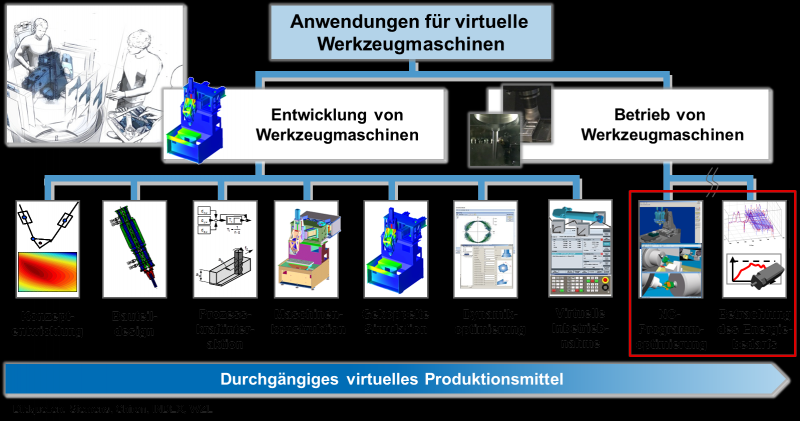

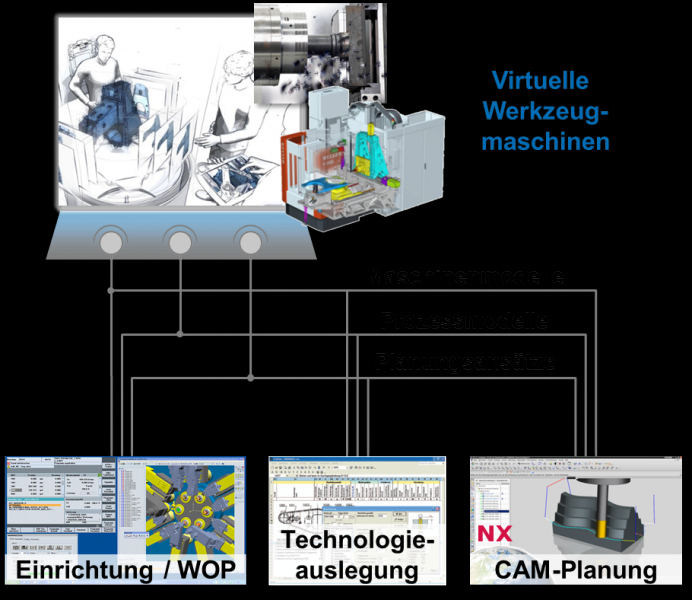

Herfs: We are very far from utilising to the full the potentials involved. There are still a lot of questions remaining to be answered: how can cross-disciplinary information from the development process be utilised? How can we succeed in automating the formation of keywords in the CAM systems (Computer Aided Manufacturing) from real control data? How can machine variants be started up in virtual mode? What’s more, machinery manufacturers lack the tools to support them in securing the logic of their control systems (PLCs).

Where are we heading when it comes to virtual simulation of the subsequent process?

Herfs: More and more, metal-cutting production processes are coming up against their limitations, because metal-cutting tools are becoming more and more performatively capable, and the stability of the machines is no longer a given – keyword: “rattling”. The planning and simulation tools used, however, assume largely idealised physical conditions: they ignore the actual interrelationships between the process and the machine. This can be remedied by expanded models that predict non-stable machining areas during virtual running-in of NC programs between process and machine.

But won’t expanded computational models be too slow?

Herfs: In the BMBF’s (German Federal Ministry for Education and Research) project, we are researching new approaches designed to reduce the simulation times involved while retaining sufficient accuracy in the results.

How is Industry 4.0 affecting the virtual machine tool?

Herfs: More indirectly at present. The discussions themed around Industry 4.0 help everyone involved to think about new utilisation scenarios. In terms of simulation, the prudent course is not to network the behavioural or process models concerned before they have been systematically examined and comprehended – and not only so that they can be networked in the context of Industry 4.0.

What constructive input can the Aachen Machine Tool Colloquium (AWK 2014) in May provide for these interrelated issues?

Herfs: Cross-specialism aspects will be addressed by the WZL’s Director Professor Christian Brecher in his paper on “Virtualisation and networking in production operations”, followed by a paper entitled “Real benefits from virtual production machines”, incorporating the practical knowledge from top-ranking machinery manufacturers.

Talking of information procurement: in this context, how do you rate the upcoming METAV 2014 – not least in regard to the conference there entitled “On the way to Industry 4.0“, at which Professor Dr. Günther Schuh from the Machine Tool Laboratory will also be presenting the perspectives as seen from Aachen?

Herfs: The METAV has for years now been committed to showcasing innovative solutions for all production-related challenges – and this applies to the field of automation as well. It has always mastered this most admirably in the past years, and has also always been an important forum for us in discussing development trends with the companies concerned, and where appropriate to map out a shared focus with them.

CV: Dr.-Ing. Werner Herfs MBA

After obtaining a degree in general electrical engineering, the Senior Academic Councillor of the Faculty for Machine Tools and Managing Senior Engineer at the Machine Tool Laboratory (WZL) at RWTH Aachen was awarded his doctorate with a dissertation on: “Model-based software in the loop simulation of machine tools”. In addition, he is actively involved in the fourth industrial revolution. Dr. Herfs was in 2012 and 2013 a member of the core authorial team drawing up recommendations regarding research and implementation for the up-to-the-future “Industry 4.0” project, and is the permanent deputy of the WZL’s Director Prof. Fritz Klocke on the academic advisory council of the “Industry 4.0” platform.

Conference tip: Industry 4.0

At the METAV 2014, ProductionNRW, the Mechanical Engineering/Production Technology Cluster, will on 12 March 2014 from 1:30 to 5:30 p.m. be hosting a conference entitled “On the way to Industry 4.0”. The event is designed to provide orientation for vendors and potential users, and map out options for future development. The conference will be examining the subject from a user’s viewpoint (“When cars talk to filling stations” “Industry 4.0 – more than just machine networking”), from the perspective of the scientist Prof. Dr. Günther Schuh from the Machine Tool Laboratory in Aachen, and from the angle of the electronics sector (security as a precondition for Industry 4.0). Recommended action for vendors and users will be mapped out in the final platform discussion.

www.produktion.nrw.de (registration: [email protected])

Background

METAV 2014 in Düsseldorf

The next METAV will be held in Düsseldorf from 11 to 15 March 2014. In the even-numbered years, it is now firmly established as an important technology window showcasing the entire spectrum of production technology for manufacturers and customers from all over Europe. The METAV showcases the entire spectrum of production technology, focusing primarily on machine tools, manufacturing systems, high-precision tools, automated materials flows, computer technology, industrial electronics, and accessories. The target group for the METAV’s visitors includes all branches of industry that machine metal, particularly machinery and plant manufacturers, the automotive industry and its component suppliers, the aerospace sector, the electrical engineering industry, energy and medical technology, plus metalworking and the craft sector. At the last METAV in 2012, around 700 exhibitors from 26 different countries showcased their products, their manufacturing solutions and their service capabilities. They attracted around 40,700 experts from more than 30 different nations.

New at METAV 2014: in conjunction with Messe Erfurt, the METAV’s organiser VDW will for the first time be addressing the issue of additive manufacturing in medical technology under the aegis of the Metal meets Medical special show.

Your contact person

Machine Tool Laboratory RWTH Aachen

Dr.-Ing. Werner Herfs MBA

Managing Senior Engineer and

Senior Academic Councillor

Steinbachstrasse 19

52074 Aachen

GERMANY

Tel. +49 241 80-27410

[email protected]

www.wzl.rwth-aachen.de

You will find texts and pictures on the internet under www.metav.com in Press Service. You can also visit the METAV through our social media channels:

Germany

Germany