Vision Wide Tech

Products

Vision Wide Always Wide Your Vision.

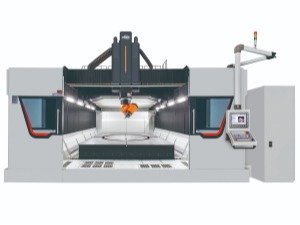

Boring and milling machines, gantry type

3+2 axes Gantry Type Machining Center

|

Boring and milling machine, gantry type

Vision Wide Tech Co. Ltd.

Boring and milling machines, gantry type

GSA

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1410 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 73500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

GSA Series 3+2 axis Gantry Type Machining Center, provided high accuracy performance in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the IAC-indexing attached head to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSA Series had an excellent dynamic performance on one-piece structural and equipped IAC 2-axis head to achieve 5-axis accuracy performance.

IAC- Indexing Attached head

Above 40kW spindle driving capacity

Auto tool clamping

Auto indexing: B axis 1? / C axis 1?

Spindle cooling device

High Tool clamping force: 20kN

15,000rpm spindle speed

IAC- Indexing Attached head

Above 40kW spindle driving capacity

Auto tool clamping

Auto indexing: B axis 1? / C axis 1?

Spindle cooling device

High Tool clamping force: 20kN

15,000rpm spindle speed

3-axis Gantry Type Machining Center

|

Boring and milling machine, gantry type

Vision Wide Tech Co. Ltd.

Boring and milling machines, gantry type

GS

| Workspace |

|

| 3000 mm | |

| 3000 mm | |

| 2000 mm | |

| 1200 mm | |

| 5000 kg | |

| Travel |

|

| 3000 mm | |

| 2000 mm | |

| 1000 mm | |

| Machine characteristics |

|

| 41500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

GS series, the Gantry CNC machining center of Vision Wide, featured with box structural design that is suitable for limited working space, and its one-piece design of work table and columns provides stable, speedy feeding performance that meets precision mold and aluminum cutting requirements.

GS CNC gantry type machining center performs efficient productivity with powerful spindle and best structural configuration that gives you smooth and fine surface within the available time. Its maximal rapid traverse of 3 axes reaches 24 m/ min, and the maximal cutting feed rate is 24,000 mm/ min.

Combination of columns, bed, and table in one piece casting, the Pyramid type weight distribution by the spindle, ran, cross beam, and bed arrangement.

X-axis with dual direct-driven servo motor, plus dual linear scales can ensure positioning accuracy at high-speed motion.

Z-axis is direct-driven, by servo motor prevents the error from indirect-driven between mechanisms, decreases power consumption, and improves Z-axis motion performance efficiently.

Direct-driven spindle 15,000rpm, low noise, backlash, vibration, and power consumption can ensure high work-piece surface accuracy after rapid cutting.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

GS CNC gantry type machining center performs efficient productivity with powerful spindle and best structural configuration that gives you smooth and fine surface within the available time. Its maximal rapid traverse of 3 axes reaches 24 m/ min, and the maximal cutting feed rate is 24,000 mm/ min.

Combination of columns, bed, and table in one piece casting, the Pyramid type weight distribution by the spindle, ran, cross beam, and bed arrangement.

X-axis with dual direct-driven servo motor, plus dual linear scales can ensure positioning accuracy at high-speed motion.

Z-axis is direct-driven, by servo motor prevents the error from indirect-driven between mechanisms, decreases power consumption, and improves Z-axis motion performance efficiently.

Direct-driven spindle 15,000rpm, low noise, backlash, vibration, and power consumption can ensure high work-piece surface accuracy after rapid cutting.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

GSF Series

|

Boring and milling machine, gantry type

Vision Wide Tech Co. Ltd.

Boring and milling machines, gantry type

GSF

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1475 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 79500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSF Series had an excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

Backlashless driving on B/C axis? Rotation Positioning accuracy ±5”.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

Backlashless driving on B/C axis? Rotation Positioning accuracy ±5”.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

NF Series High Speed Double Column Machining Center

|

Boring and milling machine, gantry type

Vision Wide Tech Co. Ltd.

Boring and milling machines, gantry type

NF

| Workspace |

|

| 10000 mm | |

| 10000 mm | |

| 2450 mm | |

| 1500 mm | |

| 26000 kg | |

| Travel |

|

| 10100 mm | |

| 3900 mm | |

| 1400 mm | |

| Machine characteristics |

|

| 78500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Mitsubishi, Siemens | |

NF series, a 3-axis bridge-type CNC milling machining center, is one of the most attractive products of Vision Wide, for its linear guideways and Z-axis box way.

Positioning accuracy could reach ±0.005/300 mm (JIS B6333).

NF satisfies various demands in mold surface cutting, angles cutting, 3D mold cutting, and precise contour finishing, and it also completes automatic 5-face machining with specially designed accessories such as tool center point compensation, auto multi-angle head attachments, and auto tool change system.

High rigidity box base, best span work table guideways, and wider load dimension ensured the best level of dynamic accuracy.

Cross-section square beam enabled the centroid of the head close to the beam center to ensure the heavy cutting ability.

Fully auto 5-face machining capacity

Auto head change: 90º head/extension head / universal head

Vertical and horizontal auto tool change for 90º head.

AC 3-axis mechanical coordinates system

Positioning accuracy could reach ±0.005/300 mm (JIS B6333).

NF satisfies various demands in mold surface cutting, angles cutting, 3D mold cutting, and precise contour finishing, and it also completes automatic 5-face machining with specially designed accessories such as tool center point compensation, auto multi-angle head attachments, and auto tool change system.

High rigidity box base, best span work table guideways, and wider load dimension ensured the best level of dynamic accuracy.

Cross-section square beam enabled the centroid of the head close to the beam center to ensure the heavy cutting ability.

Fully auto 5-face machining capacity

Auto head change: 90º head/extension head / universal head

Vertical and horizontal auto tool change for 90º head.

AC 3-axis mechanical coordinates system