Vision Wide Tech

Products

Vision Wide Always Wide Your Vision.

Turning and milling centres

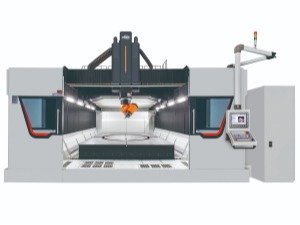

3+2 axes Gantry Type Machining Center

|

Turning and milling centre

Vision Wide Tech Co. Ltd.

Turning and milling centres

GSA

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1410 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 73500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

GSA Series 3+2 axis Gantry Type Machining Center, provided high accuracy performance in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the IAC-indexing attached head to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSA Series had an excellent dynamic performance on one-piece structural and equipped IAC 2-axis head to achieve 5-axis accuracy performance.

IAC- Indexing Attached head

Above 40kW spindle driving capacity

Auto tool clamping

Auto indexing: B axis 1? / C axis 1?

Spindle cooling device

High Tool clamping force: 20kN

15,000rpm spindle speed

IAC- Indexing Attached head

Above 40kW spindle driving capacity

Auto tool clamping

Auto indexing: B axis 1? / C axis 1?

Spindle cooling device

High Tool clamping force: 20kN

15,000rpm spindle speed

ASM Series 5-axis Universal Machining Center

|

Turning and milling centre

Vision Wide Tech Co. Ltd.

Turning and milling centres

ASM

| Workspace |

|

| 1200 mm | |

| 1060 mm | |

| 1500 mm | |

| Travel |

|

| 1000 mm | |

| Machine characteristics |

|

| 50000 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate, and synchronized axes machining, especially for aerospace components, tire molds, turbine blades, and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between the tool center point and B-axis transmission.

Positioning P0.006mm

Repeatability Ps0.0055mm

Spindle thermal compensation 0.02 mm

Rapid Traverse 40m/min

Acceleration 0.3G

Cutting Feed rate 24 m/min

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between the tool center point and B-axis transmission.

Positioning P0.006mm

Repeatability Ps0.0055mm

Spindle thermal compensation 0.02 mm

Rapid Traverse 40m/min

Acceleration 0.3G

Cutting Feed rate 24 m/min

GSF Series

|

Turning and milling centre

Vision Wide Tech Co. Ltd.

Turning and milling centres

GSF

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1475 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 79500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSF Series had an excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

Backlashless driving on B/C axis? Rotation Positioning accuracy ±5”.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

Backlashless driving on B/C axis? Rotation Positioning accuracy ±5”.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

VT Series Vertical Turning Lathe

|

Turning and milling centre

Vision Wide Tech Co. Ltd.

Turning and milling centres

VT

| Workspace |

|

| 1600 mm | |

| 1650 mm | |

| Travel |

|

| 950 mm | |

| Machine characteristics |

|

| 8000 kg | |

| Machine control |

|

| Fanuc, Siemens | |

Complex Vertical Turning Milling Solution

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance

VTM Series Vertical Turning Lathe

|

Turning and milling centre

Vision Wide Tech Co. Ltd.

Turning and milling centres

VTM

| Workspace |

|

| 1600 mm | |

| 1600 mm | |

| Travel |

|

| 950 mm | |

| Machine characteristics |

|

| 8000 kg | |

| Machine control |

|

| Fanuc, Siemens | |

Complex Vertical Turning Milling Solution

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance