Vision Wide Always Wide Your Vision.

Universal machining centres

|

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1410 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 73500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

IAC- Indexing Attached head

Above 40kW spindle driving capacity

Auto tool clamping

Auto indexing: B axis 1? / C axis 1?

Spindle cooling device

High Tool clamping force: 20kN

15,000rpm spindle speed

|

| Workspace |

|

| 1200 mm | |

| 1060 mm | |

| 1500 mm | |

| Travel |

|

| 1000 mm | |

| Machine characteristics |

|

| 50000 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between the tool center point and B-axis transmission.

Positioning P0.006mm

Repeatability Ps0.0055mm

Spindle thermal compensation 0.02 mm

Rapid Traverse 40m/min

Acceleration 0.3G

Cutting Feed rate 24 m/min

|

| Workspace |

|

| 10000 mm | |

| 10000 mm | |

| 3000 mm | |

| 2715 mm | |

| 26000 kg | |

| Travel |

|

| 10100 mm | |

| 4200 mm | |

| 1400 mm | |

| Machine characteristics |

|

| 100000 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

BM series 5 faces machines, with typical VW products features of rigid structure and high precision, is unique by the features of movable cross rail and W-axis feed cutting synchronic with another axial feeding. The max. height for workpiece & machining is 2,450mm & 2,400mm.

The movable cross rail can be positioned precisely by dual synchronized servo motors driving system. Besides, it can carry precision feeding and heavy cutting on W-axis.

The rationing hydraulic system precisely controls the parallelism of cross rail travel, even with different positions of the headstock on the Y-travel. Dual cylinders offer strong support for W-axis smooth movement.

Double beams configuration: Fixed beam to keep the best parallelism and maintain the structural rigidity; Movable beam to have the dynamic straightness and sustain the cutting power.

A precise clamping device can hold the cross beam tightly, well controlling and supporting the spindle cutting accuracy.

Automatic horizontal and vertical tool changer.

Automatic head magazine (one head).

AH attachment-Automatic 5-face function with 700mm longer Y-travel.

|

| Workspace |

|

| 8000 mm | |

| 8000 mm | |

| 2450 mm | |

| 1285 mm | |

| 24000 kg | |

| Travel |

|

| 8100 mm | |

| 3300 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 86000 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

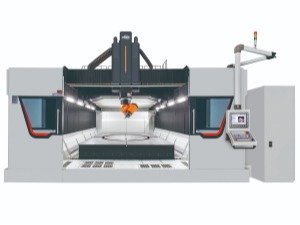

FA series, the first 5-axis bridge type CNC milling machining center of Vision Wide, was released in 2014, and it provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping.

Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. FA series had an excellent dynamic performance on XYZ axes and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

Structural rigidity was optimized by double column/bridge type structure design enabling a wider machining range.

5 axes dynamic rotation synchronization accuracy (TCPM) 0.04mm

Auto measurement compensation for rotation axis accuracy

Spindle vibration lower than 1 mm/sec

Auto measurement compensation for tool accuracy

Not affected by spindle thermal variation and environment temperature change, thermal elongation less than 0.02mm

Multi-axis synchronous head machining accuracy to meet the demand for parts processing

Vision Wide is a recognized specialist in 5-axis machining centers. We have vast experience and know-how to help clients solve machining problems. We manufacture stable and reliable machining centers via a set of strict production and QC procedures to provide the customers with quality technical service, enjoying profits and growing together with our sales partners. Any suggestion, question or commentary regarding CNC machining, please don't hesitate to submit them to our Customer Service Center.

Vision Wide is a recognized specialist of 5-axis machining centers. We have vast experience and know-how to help clients solve machining problems. We manufacture stable and reliable machining centers via a set of strict production and QC procedures to provide the customers with quality technical service, enjoying profits and growing together with our sales partners. Any suggestion, question or commentary regarding CNC machining, please don't hesitate to submit them to our Customer Service Center.

|

| Workspace |

|

| 6000 mm | |

| 6000 mm | |

| 3200 mm | |

| 1475 mm | |

| 5000 kg | |

| Travel |

|

| 6000 mm | |

| 3200 mm | |

| 1200 mm | |

| Machine characteristics |

|

| 79500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

Backlashless driving on B/C axis? Rotation Positioning accuracy ±5”.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

|

| Workspace |

|

| 10000 mm | |

| 10000 mm | |

| 2450 mm | |

| 1500 mm | |

| 26000 kg | |

| Travel |

|

| 10100 mm | |

| 3900 mm | |

| 1400 mm | |

| Machine characteristics |

|

| 78500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Mitsubishi, Siemens | |

Positioning accuracy could reach ±0.005/300 mm (JIS B6333).

NF satisfies various demands in mold surface cutting, angles cutting, 3D mold cutting, and precise contour finishing, and it also completes automatic 5-face machining with specially designed accessories such as tool center point compensation, auto multi-angle head attachments, and auto tool change system.

High rigidity box base, best span work table guideways, and wider load dimension ensured the best level of dynamic accuracy.

Cross-section square beam enabled the centroid of the head close to the beam center to ensure the heavy cutting ability.

Fully auto 5-face machining capacity

Auto head change: 90º head/extension head / universal head

Vertical and horizontal auto tool change for 90º head.

AC 3-axis mechanical coordinates system

|

| Workspace |

|

| 4000 mm | |

| 4000 mm | |

| 1800 mm | |

| 1150 mm | |

| 12000 kg | |

| Travel |

|

| 4100 mm | |

| 2700 mm | |

| 1020 mm | |

| Machine characteristics |

|

| 33500 kg | |

| Machine control |

|

| Heidenhain, Fanuc, Mitsubishi, Siemens | |

Its full casting structure provides long-term accuracy stability, and an ultra-wide column structure with a big dimension surface provides the best rigid support for the spindle and YZ axis.

Worth value, excellent manufacturing quality, and a complete range of specifications.

Ultra-wide base of X axis with thick high rigidity table enhances table load capacity and ensures the best dynamic level accuracy.

Large stepped design of Y axis makes guide ways close to beam and spindle which effectively increases the rigidity of cutting load.

Z axis 15m rapid traverse, high acceleration/deceleration performance to achieve contour accuracy of high-speed mold machining.

Spindle and thermal compensation function for environmental temperature change can be chosen to ensure the accuracy change within 0.02mm which is influenced by environmental temperature change.

|

| Workspace |

|

| 1600 mm | |

| 1650 mm | |

| Travel |

|

| 950 mm | |

| Machine characteristics |

|

| 8000 kg | |

| Machine control |

|

| Fanuc, Siemens | |

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance

|

| Workspace |

|

| 1600 mm | |

| 1600 mm | |

| Travel |

|

| 950 mm | |

| Machine characteristics |

|

| 8000 kg | |

| Machine control |

|

| Fanuc, Siemens | |

Table dia.1250-5000mm available

One piece design machine bed with strong rigidity

Workpiece spindle driven system as full gear transmission with high torque and precise accuracy

Module design column with extension possibility

Directly-drive tool spindle could install motor up to 37kw

Patent design tool clamping system with clamping force 8 tons

Multi-function magazine with large storage

Patent design high pressure coolant system up to 125 bar

X axis with full stroke able to probe complete workpiece dia.

Module design hydraulic and pneumatic system for easy maintenance

|

| Workspace |

|

| 60000 mm | |

| 60000 mm | |

| 3500 mm | |

| 2150 mm | |

| 5000 kg | |

| Travel |

|

| 60000 mm | |

| 4200 mm | |

| 1400 mm | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

Fully automatic multi-face machining: It can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

Milling and turning compound multitask: This machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

|

| Workspace |

|

| 60000 mm | |

| 60000 mm | |

| 6100 mm | |

| 3500 mm | |

| 5000 kg | |

| Travel |

|

| 60000 mm | |

| 5700 mm | |

| 3000 mm | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

XMF series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

Fully automatic multi-face machining: It can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

Milling and turning compound multitask: This machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

|

| Workspace |

|

| 60000 mm | |

| 60000 mm | |

| 5700 mm | |

| 3050 mm | |

| 5000 kg | |

| Travel |

|

| 60000 mm | |

| 5700 mm | |

| 2200 mm | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

XML series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

Fully automatic multi-face machining: It can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

Milling and turning compound multitask: This machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

|

| Workspace |

|

| 60000 mm | |

| 60000 mm | |

| 5200 mm | |

| 2200 mm | |

| 5000 kg | |

| Travel |

|

| 60000 mm | |

| 5200 mm | |

| 2200 mm | |

| Machine control |

|

| Heidenhain, Fanuc, Siemens | |

XMS series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

Fully automatic multi-face machining: It can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

Milling and turning compound multitask: This machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.