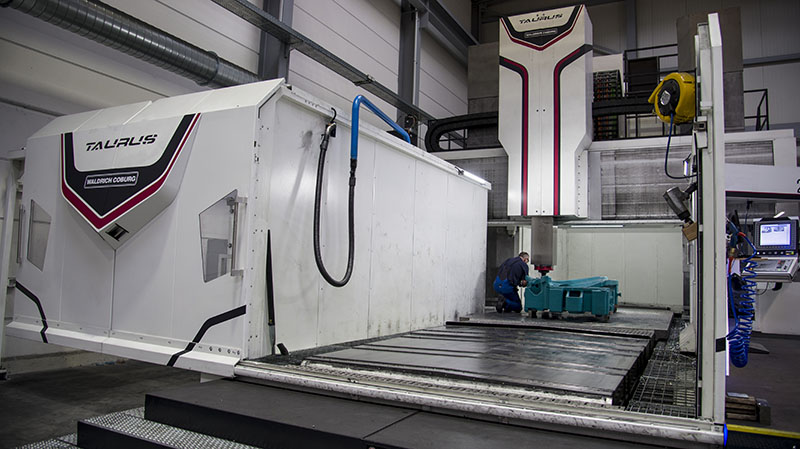

Marcus Friedrich is Managing Director of company FMF-WWF Werkzeug- und Prototypenbau GmbH located in Hardthausen-Gochsen/Germany. The company is a traditional automotive part supplier and decided for a TAURUS 30 TNC 640. This machine was first choice because of the high-accuracy and milling performance and hydrostatic in all axes, resulting in excellent damping behavior. Another advantage is the good service of WALDRICH COBURB.

WALDRICH COBURG: Marcus Friedrich, why have you decided for a TAURUS?

Marcus Friedrich: The hydrostatic guideways in all axes was an important decision criterion for the TAURUS. The damping characteristics, combined with an almost wear-free running of the hydrostatic make the machine unique in this range. Another factor was the high process stability during roughing operation. The Montronix machine airbag is working very well.

WALDRICH COBURG: And what about the control system? Also a strong reason to buy a TAURUS?

Markus Friedrich: Yes, of course, we have already been using Heidenhain controls at FMF-WWF. If the machine was not offered with a control system already in use in our company, we had not decided for a TAURUS.

WALDRICH COBURG: The TAURUS design was awarded several times, but you mentioned that the performance is more essential. What has changed in terms of productivity since TAURUS is in operation?

Markus Friedrich: We can work more efficient in the precision abrasive finishing due to the movable W-axis and the retracted Z-axis. We achieve good results in single part machining. Now complete machining is also possible due to the tool- and head-changer. The efficiency depends on the type of operation and the number of pieces. We estimate a 10% productivity increase in this field.

WALDRICH COBURG: Until now you have only been working as automotive part supplier. What kind of parts are produced on the TAURUS?

Marcus Friedrich: casting base frames, large slide units and contour parts.

WALDRICH COBURG: You have already experience in the preparation of machine foundations. The perfect hardening of the foundation played an important role. What is necessary to achieve a good result?

Marcus Friedrich: We have used our long experience and started very early with the digging works to have enough time for the foundation drying.

WALDRICH COBURG: What is the opinion of your people about the machine, a critical one or gives the TAURUS reason for even more motivation ?

Marcus Friedrich: It is the same with every other new investment, our people are motivated and give everything to meet the challenge. We have chosen people with much experience to operate the new TAURUS. From ergonomic point of view, the machine is perfectly adapted to our operators’ needs.

WALDRICH COBURG: Strong and wear-free are the most important values of the TAURUS for us. In the development, all aspects were considered to create an excellent milling machine.

What is your experience with the TAURUS?

Marcus Friedrich: The concept of the machine and the workmanship are very good and allow a production increase. However, it is a new machine type and there is still potential for adjustments in our company-specific working environment. In case of problems, we can rely on the fast service from WALDRICH COBURG.

WALDRICH COBURG: This is an important point. We set high priority on a fast and competent teleservice to achieve shortest reaction times. What is your opinion about the service?

Marcus Friedrich: Service is one of the most important aspects when making an investment. Teleservice is the best way to get an impression of the quality of the WALDRICH COBURG personnel. The WALDRICH COBURG service is absolutely reliable in all respects.

FMW-WWF Werkzeug- und Prototypenbau GmbH is an owner-managed medium-sized company. The company is an important partner for the automotive industry and is renowned in automotive development, prototype and industrial production equipment. Developing of methods for car bodies or application of customer methods in series trials are another field of activity.

High-efficient CAM processes are the basis for economic CNC-machining. FMF-WWF ensures highest precision in the milling process by means of modern HSC milling centers. A low rework level in tool making and tryout reduces the order process times. For structural die cast components FMF-WWF provides mechanical processing, straightening processing, measuring and assemblies, even for complex parts in the motor racing sector!

FMF-WWF

Werkzeug- und Prototypenbau GmbH

Untere Au 2

74239 Hardthausen-Gochsen

GERMANY

Germany

Germany