Zimmer Group

Products

THE KNOW-HOW FACTORY

Zimmer GmbH

Brakes

Clamping elements | electric Series LKE

With over 4,000 products and more than 20 years of development and market experience, the Zimmer Group is the world market leader in linear technology and in the field of clamps and brakes on profiled and round shaft guides. The new LKE series convinces - in contrast to a pneumatic solution - above all with its integrated status query (open/closed), which is output via digital status signals. The kinematics are carried out via an eccentric shaft with mechanical self-locking (bistable). Due to the self-locking operating principle, the full holding force is maintained in the closed state in the event of a current drop or in the de-energized state (e.g. when the system is switched off). Depending on the size, the LKE series has a very high holding force of up to 1,100 N without jamming permanently. Opening and closing is performed by a 24 V DC voltage at a current consumption of max. 1.5 A. An impressive feature of the new LKE series, however, is its speed. With a closing time of approx. 400 milliseconds (depending on the size) - which corresponds to an improvement by a factor of about 7 compared to the previous model - the Zimmer Group also underlines its innovative capability in electrical clamping elements. The Zimmer Group's clamping elements have integrated electronics and can be controlled very simply via digital signals. The open and closed positions reached are each output via a pin for reliable monitoring against cable breakage. Zimmer has also come up with a very interesting finesse for its new series, e.g. to correct any rail tolerances. Typical rail tolerances of ± 0.05 millimeters can be compensated for on a scale attached to the product. The clamping elements are sealed to IP64 and have a flexible cable outlet that allows maximum use of installation space by means of adaptable cable routing, thus minimizing interference contours. With the aforementioned features, the electrical clamping elements create the conditions for high flexibility and high machine utilization, while ensuring maximum reliability in production with a B10d value of 500,000 clamping cycles.In addition, the LKEs have an important safety feature in the form of a mechanical emergency release. The clamping elements are primarily used for electrically driven linear axes. By holding the axis via the clamping element, high process forces can be absorbed while maintaining the clamping position, which exceed the forces of the linear drive many times over. The LKE series is ideally suited for use in applications without an existing pneumatic or hydraulic supply, e.g. in clean room areas or in medical and food technology.

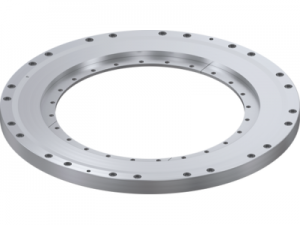

Rotary clamping element series DKHS1000

|

Brake

Zimmer GmbH

Brakes

- Highest accuracy in rotational axis

- No moving functional parts and therefore backlash-free Drive can be taken out of the drive control

- Fastest reaction time and pressureless safety function

- Due to a low displacement volume and internal stress of the housing

- Market leading cycles

- Housing strain stays below the elastic fatigue limit

Available for shaft diameters from 180mm to 460mm

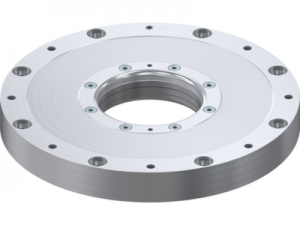

Rotary clamping element series DKPS

|

Brake

Zimmer GmbH

Brakes

- High holding torque without additional air

- Enhanced safety due to securing the

- rotation axes

- Simple status sensing

- Efficient and fast process flow

- Market leading cycles

- Leak-free thanks to a proven piston seal

Available for shaft diameters 50mm, 90mm and 160mm