Zimmer Group

Products

THE KNOW-HOW FACTORY

Gripping tools and automatic fixtures

Greiferfamilie Series 6000

|

Gripping tools and automatic fixtures

Zimmer GmbH

Gripping tools and automatic fixtures

- Electrically and positionable - for flexible handling

- Maintenance-free for up to 5 million cycles - for smooth production

- Up to 32 workpieces can be deposited

- Integrated query via IO-Link

- Power version -03 for heavy workpieces; sensitive version -31 for sensitive gripping

Convince yourself of the electric grippers in a class of their own! The 6000 series of Zimmer Group grippers can be flexibly positioned, have a high power density and convince with a longevity that is impressive (up to 5 million maintenance-free cycles). Individual force adjustment as well as position and speed control optimize the grippers of the 6000 series for use in sensitive, process-safe areas such as laboratories or medicine. IO-Link compatibility and storage of up to 32 workpieces provide maximum flexibility. Whether powerful handling including mechanical self-locking or sensitive precision - the grippers of the 6000 product family can be used in a variety of applications and are used across all industries.

2-JAW PARALLEL GRIPPER WITH LARGE STROKE

SERIES GEH6000IL

3-JAW CENTRIC GRIPPER WITH LARGE STROKE

SERIES GED6000IL

Pallet changer Series SPP

|

Gripping tools and automatic fixtures

Zimmer Group GmbH

Gripping tools and automatic fixtures

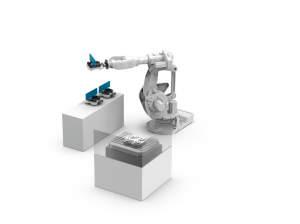

With the pallet changer, the Zimmer Group is expanding the zero-point clamping system product range. Along with changing pallets in tooling machines, it also offers numerous other applications, for example, the handling of components in portals or on robots with high repetition accuracy.

Because of the slim design and low set-up of the clamping plate and clamping pallets, you get both close-proximity pallet loading on the machine table as well as maximum use of the machine space. High clamping forces create an extraordinarily rigid system, whose excellent holding force enables the highest torque as well as a highly precise connection between the robot and the clamping plate. This makes the handling of heavier pallets, in particular, easier and safer.

Because of the slim design and low set-up of the clamping plate and clamping pallets, you get both close-proximity pallet loading on the machine table as well as maximum use of the machine space. High clamping forces create an extraordinarily rigid system, whose excellent holding force enables the highest torque as well as a highly precise connection between the robot and the clamping plate. This makes the handling of heavier pallets, in particular, easier and safer.